Pressure Drop Tables

- Series LL-STV / LL-STVL

Optional features and accessories available for this

Macon product are an extra charge, and not included

in the standard model price.

www.maconbalancing.com

Tunstall Corporation

118 Exchange Street · Chicopee, MA 01013

Phone (413) 594-8695 · Fax (413) 598-8109

Section: Components Bulletin-MB-LL-STV-STVL-0915

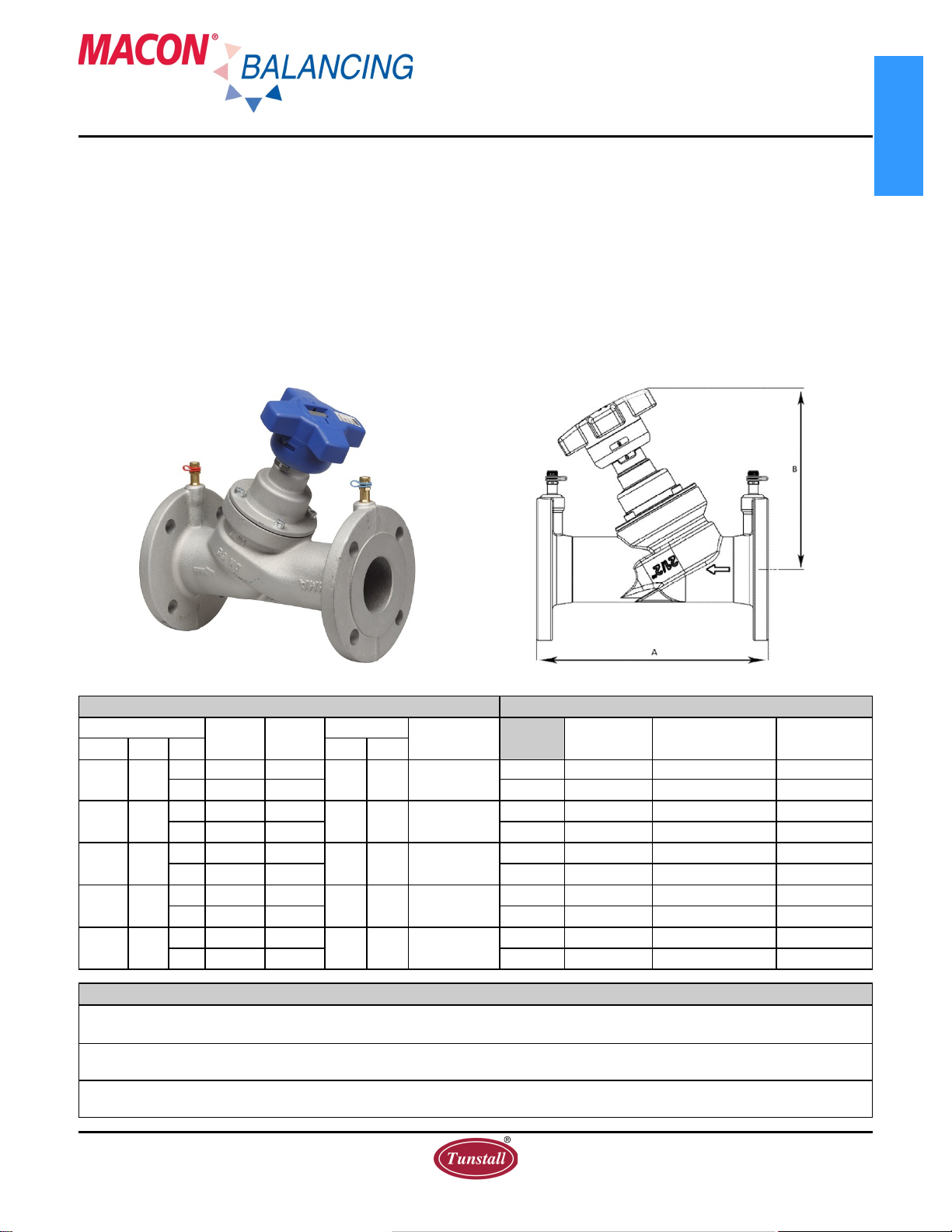

Cv Values for Valve Series LL-STV / LL-STVL

1 0.21 0.39 0.56 0.92 1.39 2.32

1.5 0.29 0.56 0.75 1.28 1.97 3.25

2 0.37 0.70 0.89 1.53 2.38 4.18

2.5 0.44 0.82 1.04 1.80 2.78 5.10

3 0.52 0.96 1.19 2.09 3.25 6.03

3.2 0.56 1.02 1.28 2.26 3.48 6.50

3.4 0.59 1.09 1.39 2.44 3.71 6.96

3.6 0.63 1.16 1.51 2.67 4.06 7.54

3.8 0.67 1.23 1.62 2.90 4.41 8.12

4 0.72 1.31 1.74 3.13 4.76 8.82

4.2 0.77 1.39 1.91 3.42 5.10 9.74

4.4 0.81 1.48 2.09 3.71 5.57 10.70

4.6 0.87 1.58 2.26 4.06 6.03 11.70

4.8 0.93 1.68 2.44 4.41 6.61 12.80

5 1.00 1.80 2.67 4.76 7.19 13.80

5.2 1.07 1.91 2.90 5.16 7.77 15.00

5.4 1.14 2.03 3.19 5.57 8.35 16.00

5.6 1.21 2.16 3.48 5.97 8.93 17.20

5.8 1.28 2.30 3.83 6.38 9.63 18.30

6 1.36 2.44 4.18 6.84 10.30 19.40

6.2 1.44 2.60 4.47 7.25 11.00 20.40

6.4 1.52 2.76 4.76 7.66 11.80 21.50

6.6 1.62 2.96 5.10 8.12 12.50 22.50

6.8 1.74 3.16 5.54 8.58 13.20 23.50

7 1.88 3.36 5.80 9.05 13.90 24.60

7.2 2.06 3.60 6.15 9.51 14.60 25.50

7.4 2.26 3.83 6.50 9.98 15.30 26.40

7.6 2.49 4.06 6.84 10.40 15.90 27.40

7.8 2.73 4.27 7.19 10.80 16.50 28.20

8 2.96 4.47 7.54 11.30 17.10 29.00

8.2 3.13 4.63 7.89 11.70 17.60 29.90

8.4 3.29 4.78 8.24 12.20 18.20 30.70

8.6 3.42 4.93 8.58 12.60 18.80 31.60

8.8 3.54 5.08 8.87 13.00 19.40 32.40

9 3.65 5.22 9.16 13.30 19.80 33.20

9.2 3.77 5.36 9.40 13.70 20.30 33.90

9.4 3.87 5.50 9.63 14.20 20.90 34.60

9.6 3.98 5.64 9.86 14.50 21.50 35.30

9.8 4.06 5.78 10.00 14.80 22.00 36.00

10 4.12* 5.92* 10.2* 15.2* 22.6* 36.5*

* Valve is fully open

Flow coefficient values (CV's) at various handwheel settings

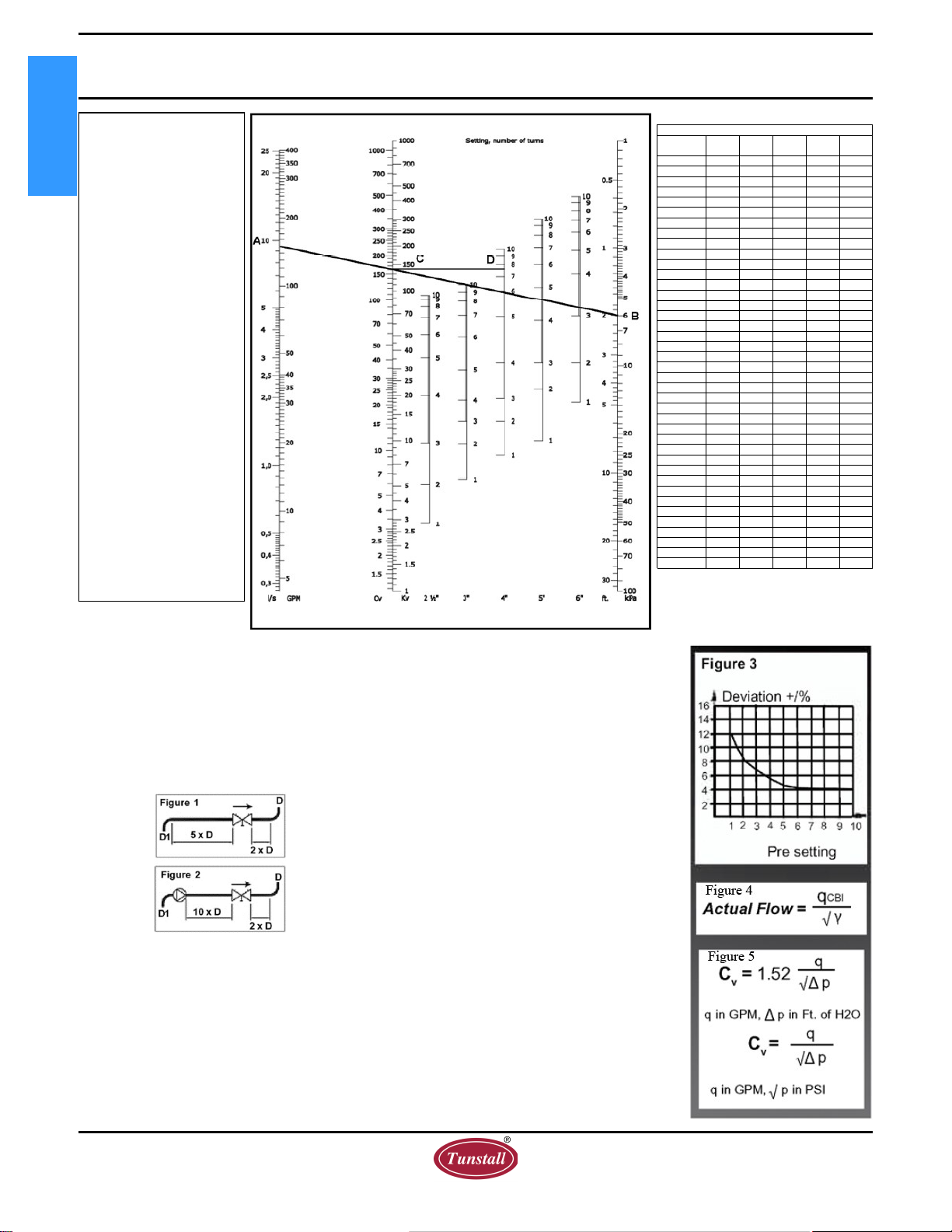

Series LL-STV &

LL-STVL 1/2” - 2”

This diagram details the

relationship between flow,

pressure drop and valve

preset points. Use the dia-

gram to select the correct

valve size and corresponding

handwheel setting to fulfill

the application requirements.

Determine the required flow

in the circuit (A) and the

pressure drop (B). Draw a

line between these two val-

ues. Read off the corre-

sponding Cv value on the Cv

scale.

Determine the valve setting,

in handwheel turns, by draw-

ing a horizontal line (D)

from the intersection point

on the Cv scale to the corre-

sponding valve setting posi-

tion.

For the highest level of accu-

racy, it is recommended to

choose a valve that has at

least 3 open turns.

Example: A 1” valve is

required to be open 8 turns for

a Cv value of 7.5 at a flow rate

of 10 gpm and a pressure drop of 4ft.

Installation Recommendations

Install the valve in the correct flow direction

according to the arrow on the valve body and the

distance parameters detailed in Figure 1.

(Note: D = pipe diameter).

For Series LL-STVL, cover the valve body with a wet

cloth when soldering to prevent premature deteriora-

tion of valve components.

When used with a pump, it is recommended to use a

straight length of pipe totaling 10 x D (instead of 5 x

D) upstream or downstream to avoid turbulence that

will affect the measuring accuracy. See Figure 2.

Turbulence can influence the measurements by up to

20% if this recommendation is not followed.

Flow Measurement & Accuracy

The measuring instrument connects to the test ports of

the valve and is pre-programmed with Macon Balanc-

ing characteristics. The pressure drop and flow read-

ings can be read off the display. If access to a Macon

Balancing instrument is unavailable, other industry

models are compatible. In addition, the flow can be

determined using the pressure drop diagram that is

included in the operating instructions with each

Macon Balancing valve.

The accuracy is highest when the valve is fully open.

Therefore, it is recommended to choose a valve that

can be opened at least three turns at the calculated

pre-setting value. Figure 3 represents the flow

measurement deviation in relation to handwheel turns.

Correction for Liquids

Applies to liquids other than water. Correct the meas-

ured flow (q) by the density (Y) according to this

formula. See Figure 4.

Sizing a Balancing Valve

When the differential pressure and design flow are

known, use this formula to calculate Cv value.

See Figure 5.

Memory Stop

1. Set valves to desired position.

2. Turn the inner stem with a 3 mm Allen wrench

in a clockwise direction until it stops.

CIRCUIT

SETTER LOW LEAD