T U R B O s . r . l . D u s t F i l t e r C o m p o n e n t s

V i a C e n t r o I n d u s t r i a l e E u r o p e o , 3 3 –T u r a t e ( C O ) I t a l y

T e l + + 3 9 0 3 6 2 5 7 4 0 2 4 F a x + + 3 9 0 3 6 2 5 7 4 0 9 2

Introduction

In today’s industrial automation market, new Turbo technologies bring many opportunities for industrial system

developers to successfully address evolving challenges.

Automation systems require cutting-edge technologies to meet customer requirements for application ranging

from programmable logic controllers (PLC’s) and industrial computers to human machine interface (HMI),

industrial peripherals and factory communication.

Turbo has developed a solution for the industrial automation industry with a platform specifically focused on the

dust emission monitoring with industrial communication capabilities, that has been designed to implement the

real-time communications technologies used in industrial automation applications.

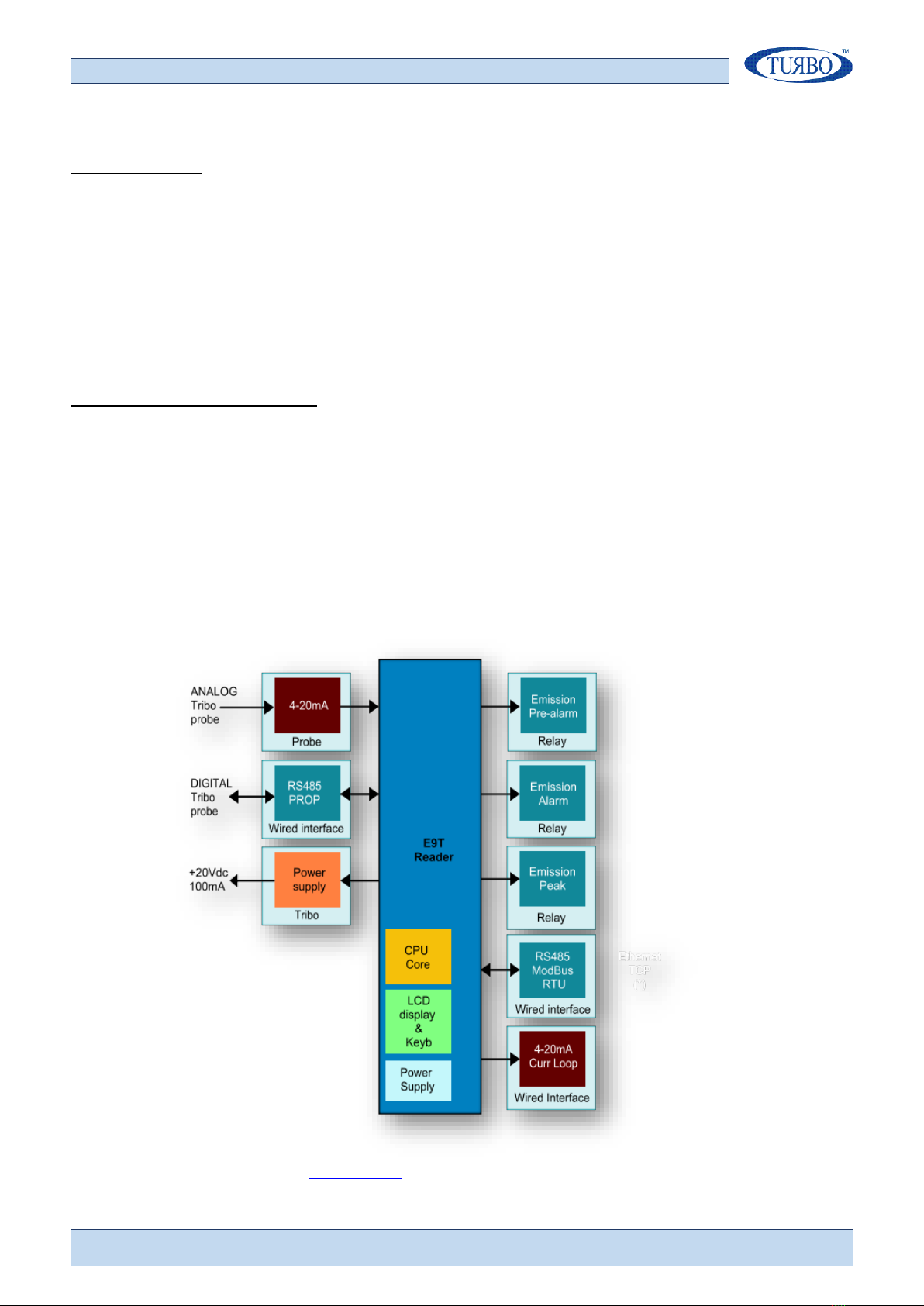

E9T triboelectric reader

The “E9T triboelectric reader”, also defined like E9T control unit, is a stand-alone electronic device connected to a

triboelectric probe and built for monitoring dust emission in chimneys of industrial systems.

Brief, the dust flowing in a chimney is detected by the triboelectric probe placed in the conduct and connected to

the E9T control unit. The triboelectric probe is able to measure the quantity of emissions flowing and immediately

communicate the measure to the E9T control unit.

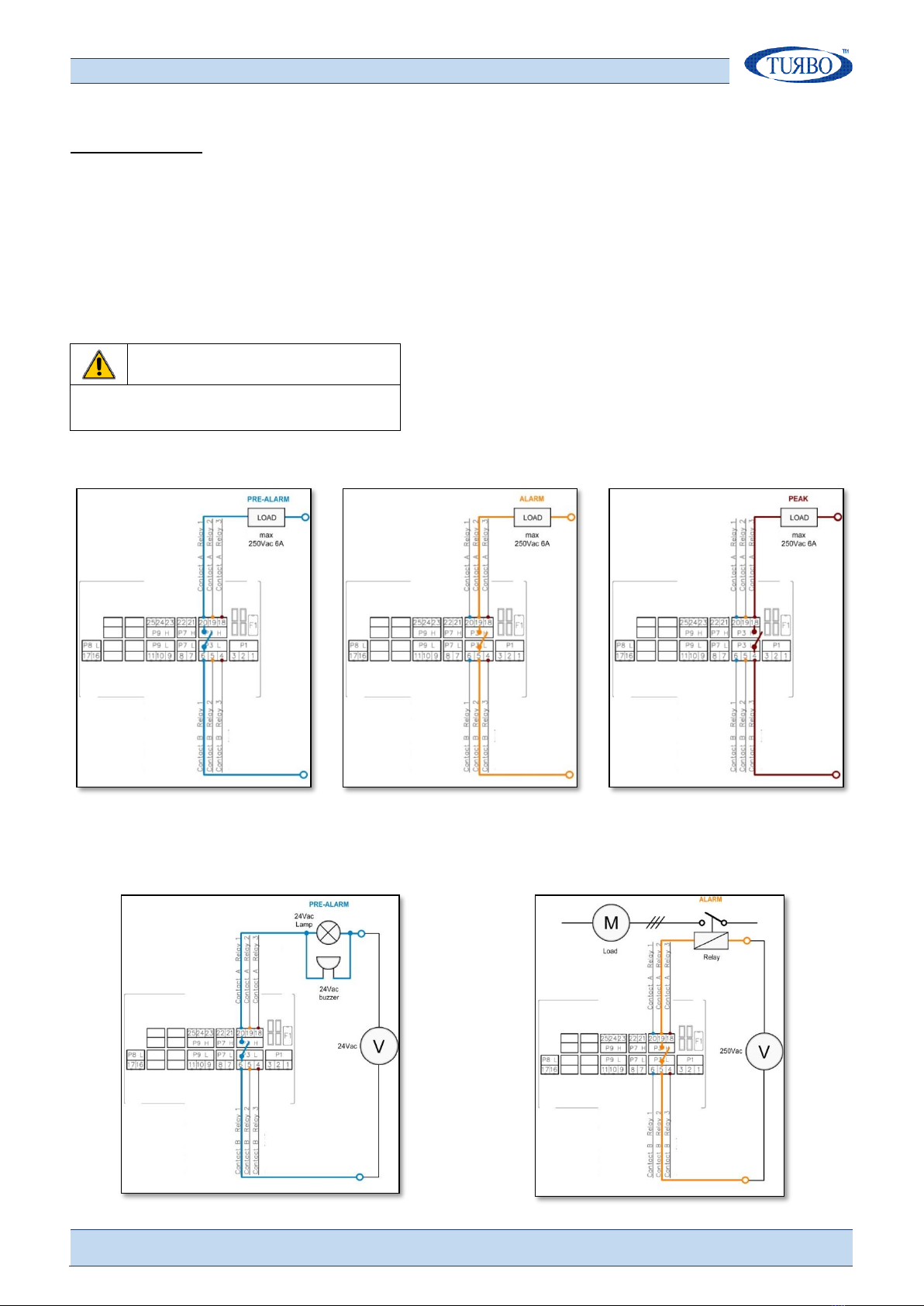

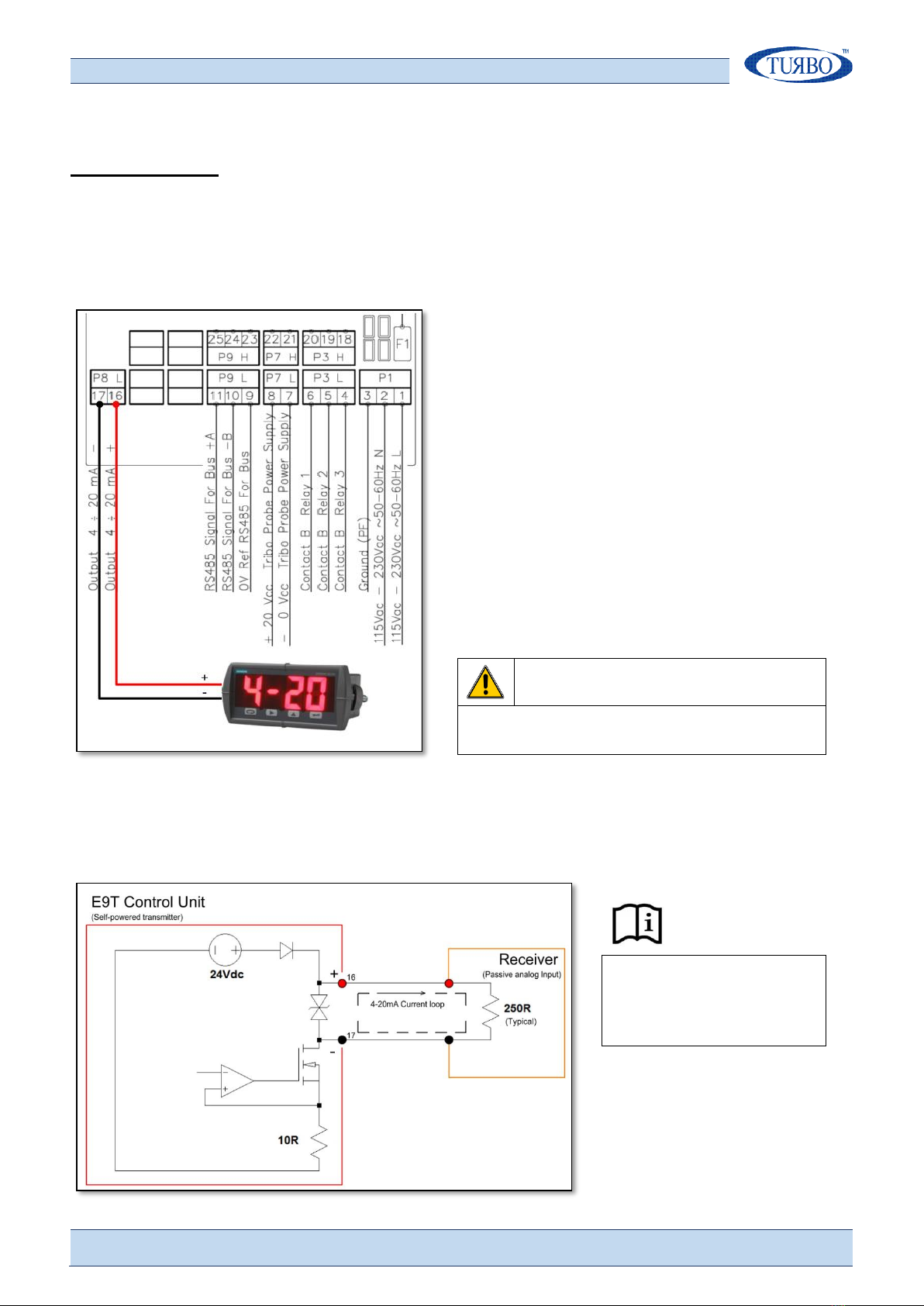

The E9T control unit is provided of LCD graphical display for visualization and local programming and a lot of I/O

lines for system interfacing in order to transmit emissions values and alarms status.

The E9T control unit schematic resources diagram is shown below: