1. - General information 5

1.1 - Introduction

1.2 - General information

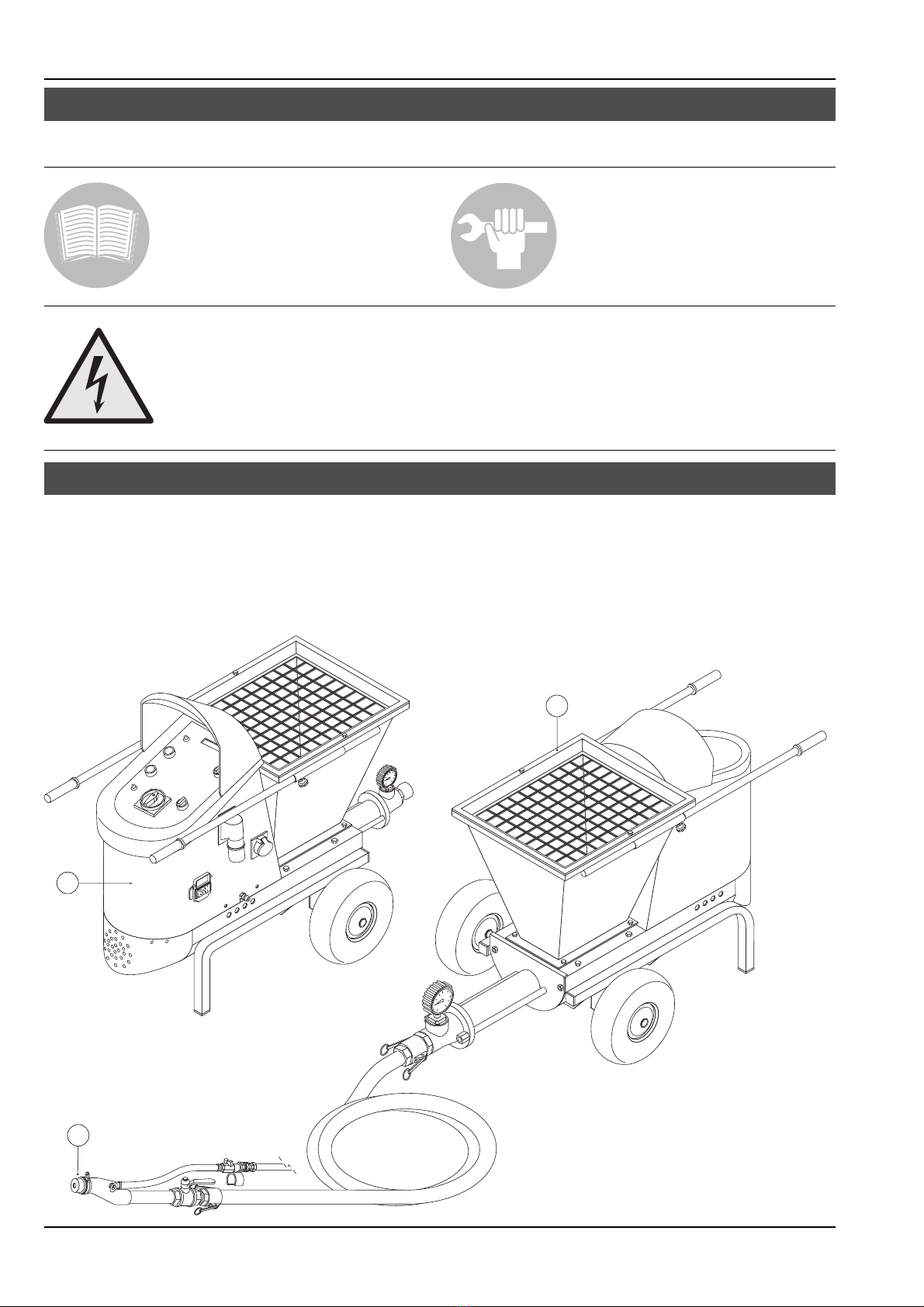

2. - Description of the machine 6

2.1 - Type of machine 6

Manufacturer’s registration plate

Location of the manufacturer’s registration plate

Location of the machine serial number

2.2 - Description of the machine 7

2.3 - Size of the machine 8

2.4 - Technical data regarding the machine 8

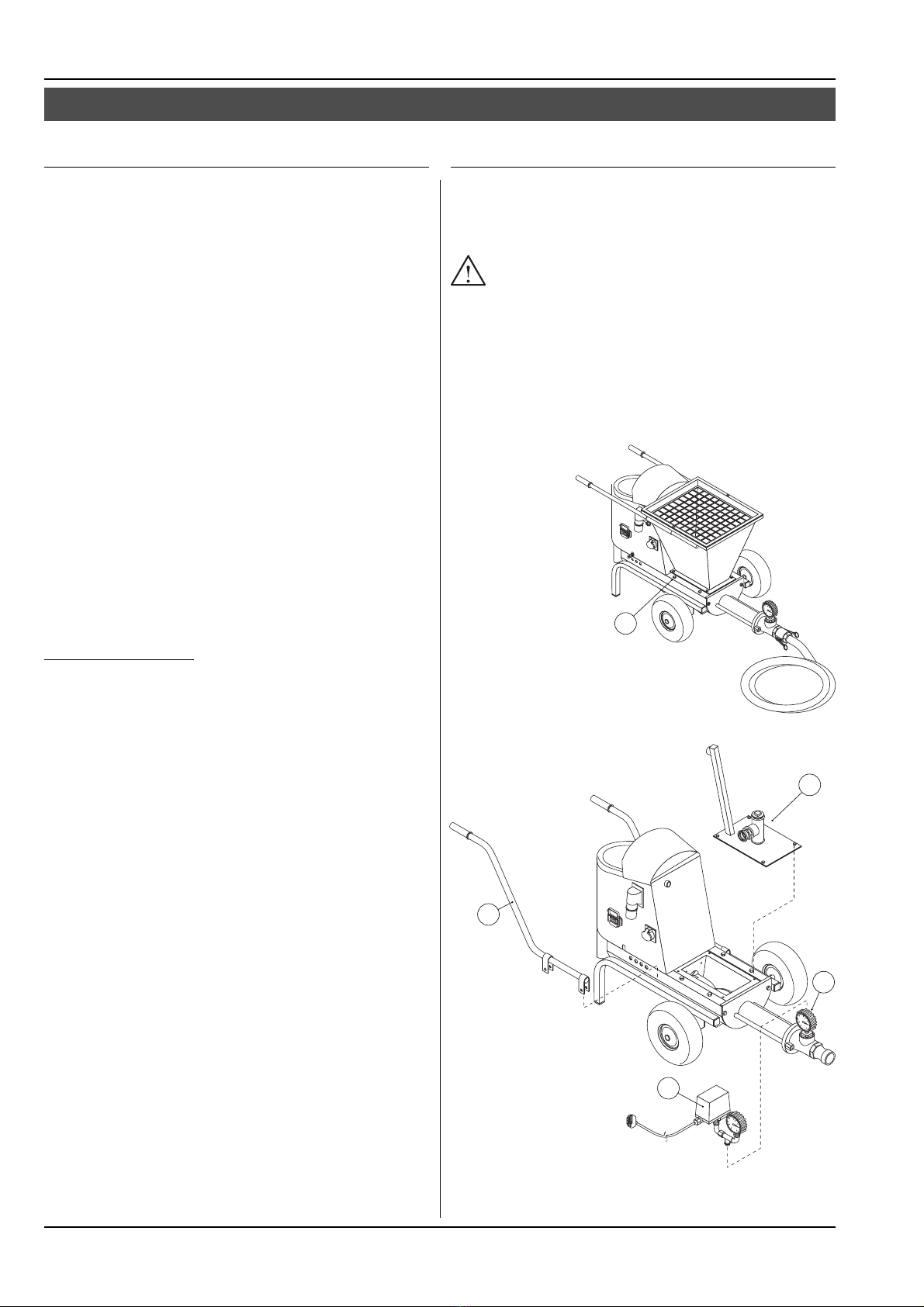

3. - Transporting the machine 9

3.1 - Transport

4. - Using the machine 9

4.1 - Operating principles 9

4.2 - Pumpable materials 10

Choosing the gun

4.2.1 - Conversion kit into admixture dosing pump 10

4.3 - First operations 12

Positioning the machine

Electrical connection

Hoses 13

Couplings

Connections 14

4.4 - Starting the machine 16

Starting the version

4.5 - Washing and stopping the machine 17

4.6 - Pumping group 18

Replacing of the pumping group

5. - Maintenance of the machine 19

5.1 - To be performed by the operator

5.2 - To be performed byauthorized personnel

Operations to be performed every 500 hours

6. - Problems – causes – remedies 20

6.1 - Mortar not flowing from the spray gun 20

6.2 - Operation to be performed by the operator 21

6.3 - Operation to be performed

by authorized personnel

7. - Responsibility of the operator 22

Table 1 - Machine body 24

Table 2 - Transmission - Worm gear pump 26

Table 3 - Switch board - Plugs 28

Table 4 - Remote control 30

Table 5 - Accessory bag DN25 - Hoses DN25 32

Table 6 - Accessory box - cod. 201.131

for ready-mixed plasters 34

DN25 ACCESSORIES

Table 7 - Accessory box- code. 201.136

for skim coats 38

Table 8 - Accessory box

cod. 201.137 e cod. 201.142

for pressure pointing

Delivery tube 40

Table 9 - Injections device 42

Table 9A - Injection pressure shut-down device 44

Table 9B - Pistola iniezioni - Tubazioni 46

Table10 - Pressure gauge – Hoses extensions 48

DN19 ACCESSORIES

Table11 - Accessory bag - Hoses

Pressure gauge 52

Table12 - Accessory box - code 201.116

for ready-mixed plastersi 54

Table13 - Accessory box - code 201.117

for skim coats 56

Table14 - Accessory box

cod. 201.118 e cod. 201.119

for pressure pointing 58

Table15 - Accessory box - cod. 201.120

for finishing coats 60

Table16 - Injections device 62

Table16A - Injection pressure shut-down device 64

ACCESSORI

Table17 - Bag squeezer 68

Table18 - Vibrating Sieve 70

Table19 - Compressor single-phase 170 l/m’ 72

Table20 - Compressor three-phase 592 l/m’ 74

Table21 - Conversion kit into admixture

dosing pump 76

WIRING DIAGRAMM

Table22 - Wiring diagramm 80

USE AND MAINTENANCE SPARE PARTS

CONTENTS