5

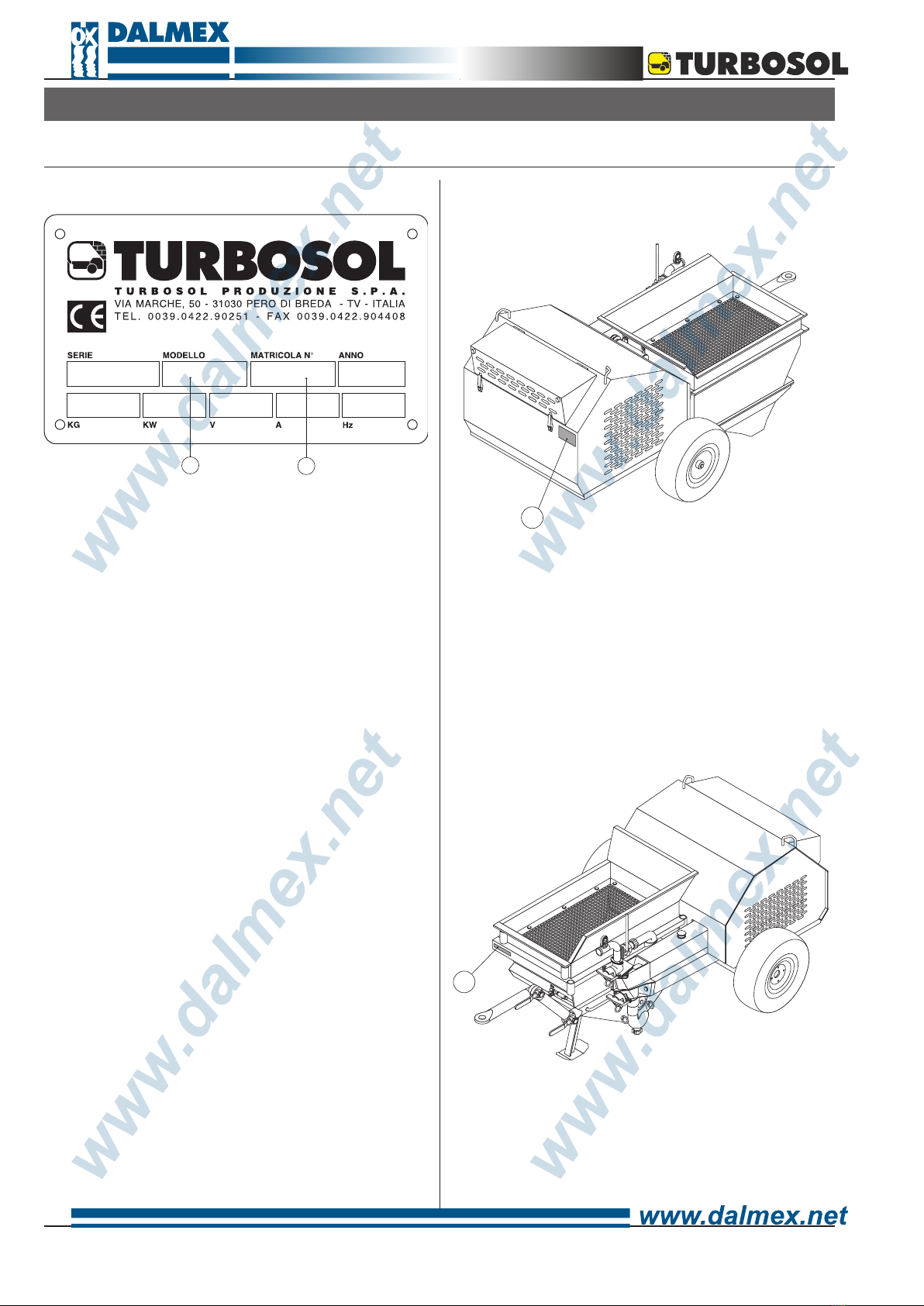

The UNI 30 mortar conveyor and sprayer machine can

be supplied with a variety of accessories. As a result,

some of the components and spare parts described

in this booklet may not be included with your own

equipment.

We have taken special care to clearly illustrate the

different variations in order to make it easier for you

to distinguish the use and maintenance instructions

applicable to your own machine.

Please read these instructions prior to starting up your

equipment and follow the instructions carefully.

For any other information you might require, TURBOSOL

PRODUZIONE S.P.A.’s customer service is at your

complete disposal.

TURBOSOL PRODUZIONE S.P.A.

Via Volta, 1

31030 Pero di Breda di Piave (TV) - ITALIA

Tel. 0039 - 0422 - 90.2.51

Fax 0039 - 0422 - 90.44.08

http://www.turbosol.it

TURBOSOL Machinery

This machinery is the product of our lengthy experience

and continuous development. The know-how thus

acquired, together with our stringent requirements

for high quality, constitutes the basic guarantee for

manufacturing low-wearing machinery which offers total

reliability at low servicing costs.

Precautions to be taken when the machine is operating

Maintenance or repair works must be carried out only

when the machine is turned off. Whatever safety devices

have been removed in order to complete such work, they

must be mounted again after maintenance has been

carried out.

Care and maintenance

Care and maintenance are vitally important in making it

possible for the machinery to operate as expected. It is

therefore essential that all maintenance will be performed

on schedule and will be carried out with extreme care.

Safety

This symbol marks each reference to safety in

this booklet, and it must be scrupulously observed.

The personnel in charge must be fully informed about

any safety regulations. Safety and accident-prevention

regulations currently in effect in your area or country

must likewise be observerd.

Training

This symbol indicates that the personnel operating

this machinery must have received special training in

regard to the correct manner in which such operation

must take place.

TURBOSOL SERVICE

For any problem related to trouble with this machinery or

when you need spare parts, contact your local Turbosol

dealer.

1.1 - INTRODUCTION 1.2 - GENERAL INFORMATION

1 - GENERAL INFORMATIONS