Inductive

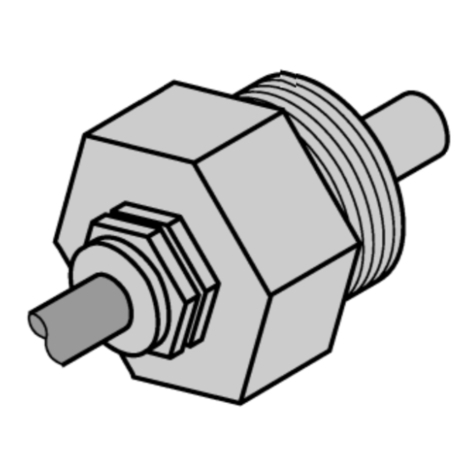

dual sensor for rotary actuators

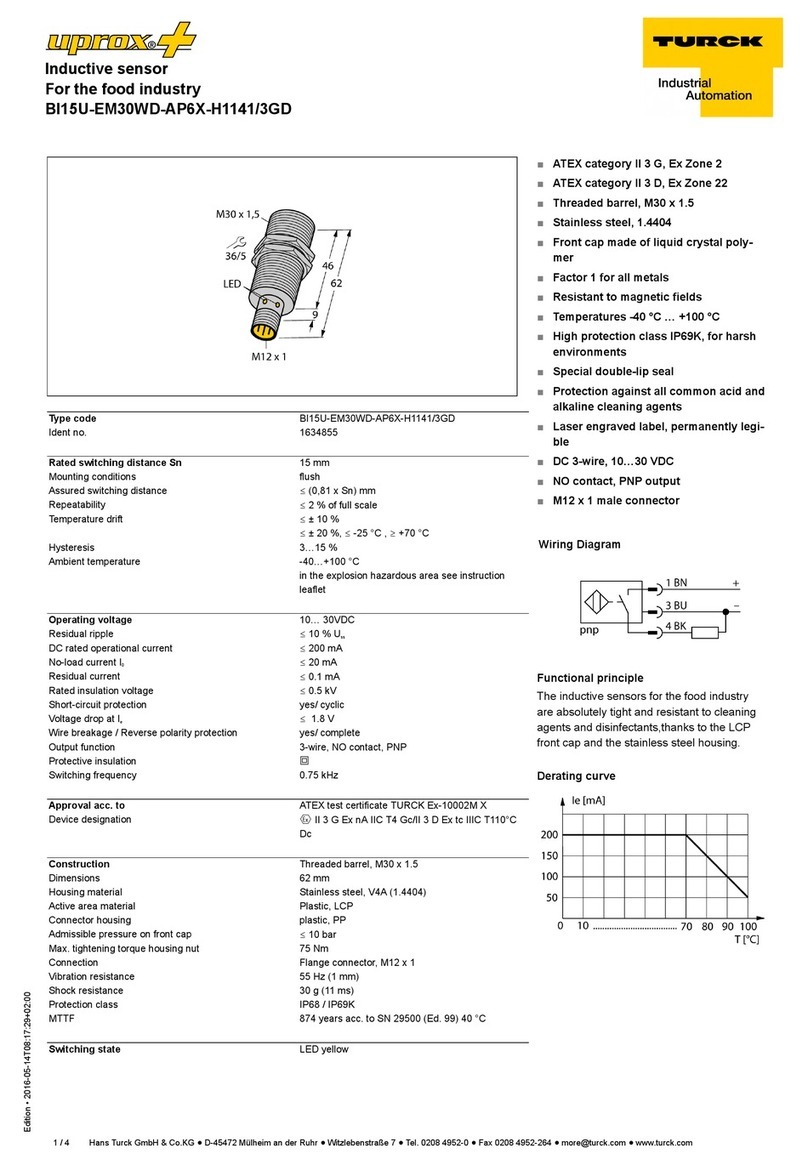

NI4-DSU35TC-2AP4X2/3GD

Edition • 2013-07-13T05:12:10+02:00

1 / 4

Hans Turck GmbH

& Co.KG

ñ D-45472 Mülheim an der Ruhr ñ Witzlebenstraße 7 ñ Tel. 0208 4952-0 ñ Fax 0208 4952-264 ñ [email protected] ñ www.turck.comType code NI4-DSU35TC-2AP4X2/3GD

Ident no. 1569911

Rated operating distance Sn 4 mm

Mounting condition non-flush

Correction factors St37 = 1; Al = 0.3; stainless steel = 0.7; Ms = 0.4

Repeatability ð 2 % of full scale

Temperaturdrift 10 %

Hysteresis 3…15 %

Ambient temperature -25…+70 °C

Operating voltage 10…65VDC

Residual ripple ð 10 % Uss

DC rated operational current ð 200 mA

No-load current I0ð 15 mA

Residual current ð 0.1 mA

Rated insulation voltage ð 0.5 kV

Short-circuit protection yes/ cyclic

Voltage drop at Ieð 1.8 V

Wire breakage / Reverse polarity protection yes/ complete

Output function 4-wire, NO contact, PNP

Valve control ð 60 V / ð 20W

Switching frequency 0.05 kHz

Approval acc. to ATEX test certificate TURCK Ex-03020H

Device designation Ex II 3 G Ex nA IIC T5 Gc/ II 3 D Ex t IIIC T100°C Dc

IP67

Design dual sensor for valve monitoring, DSU35

Dimensions 62x 60x 35 mm

Housing material Plastic, PP, yellow

Material active face Plastic, PP, Black

Connection Terminal chamber

Clamping ability ð 2.5 mm2

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP67

MTTF 2283 years acc. to SN 29500 (Ed. 99) 40 °C

Switching state ññ yellow / red

Included in scope of supply 2 ATEX cable glands (black), 2 blanking plugs for

cable glands, 1 M20x1 blanking plug

■ATEX category II 3 G, Ex Zone 2

■ATEX category II 3 D, Ex Zone 22

■Rectangular, housing DSU35

■Plastic, PP-GF30-VO

■Two outputs for monitoring the position

of rotary actuators

■Mounting on all standard actuators

■2 x NO contacts, PNP output

■DC 4-wire, 10…63 VDC

■Terminal chamber

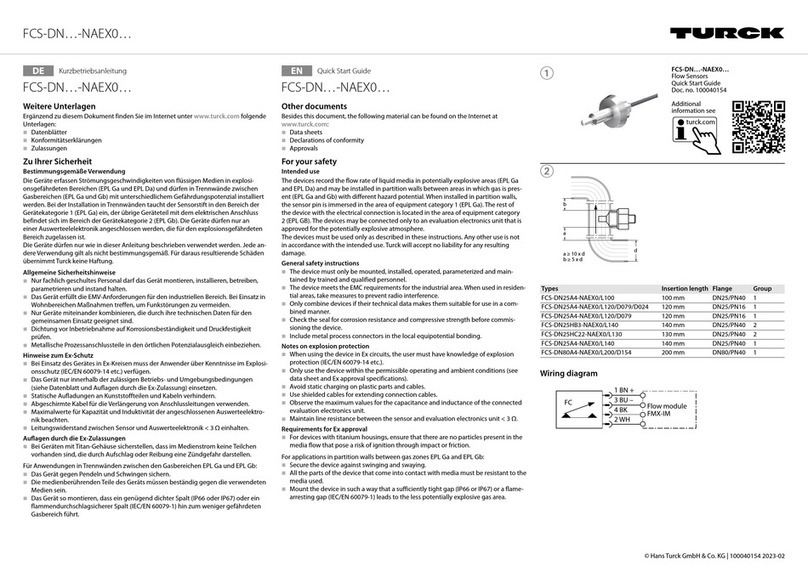

Wiring diagram

Functional principle

Inductive sensors detect metal objects con-

tactless and wear-free. Dual sensors are es-

pecially designed for position detection in ro-

tary actuators. They combine the reliability of

non-contact inductive sensors with the flexibil-

ity of a modular housing system.