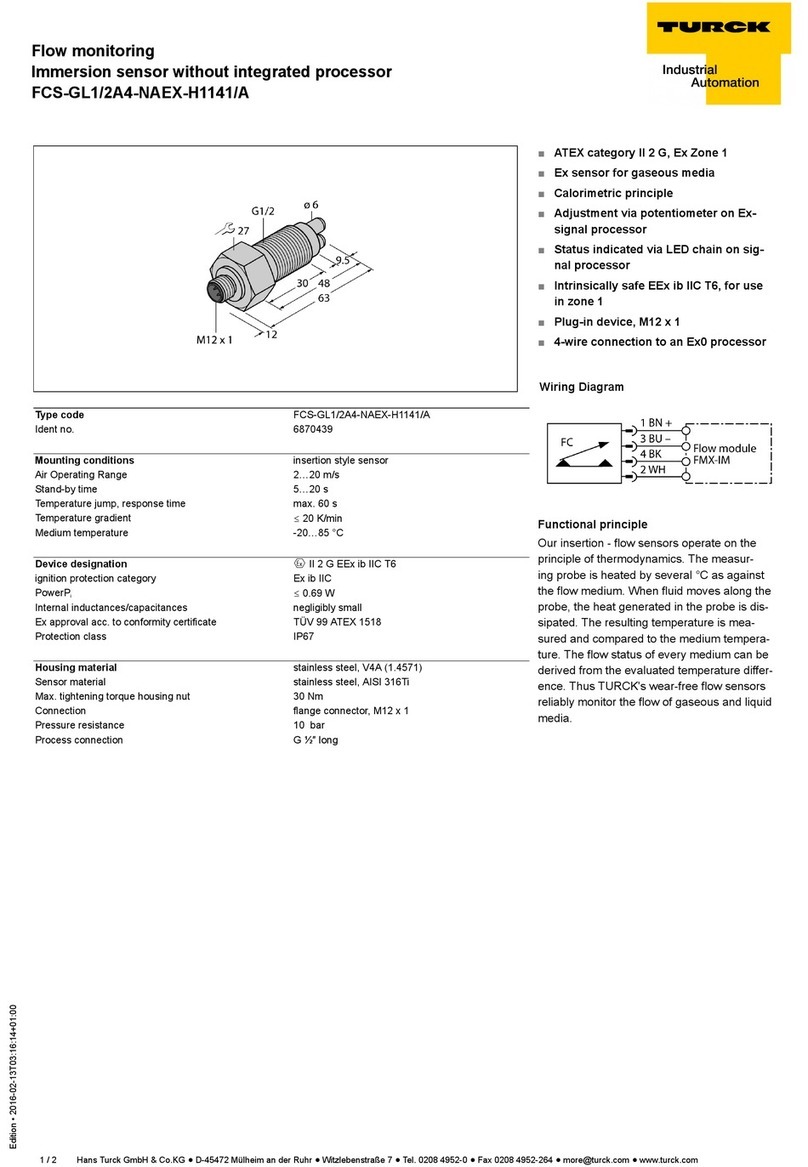

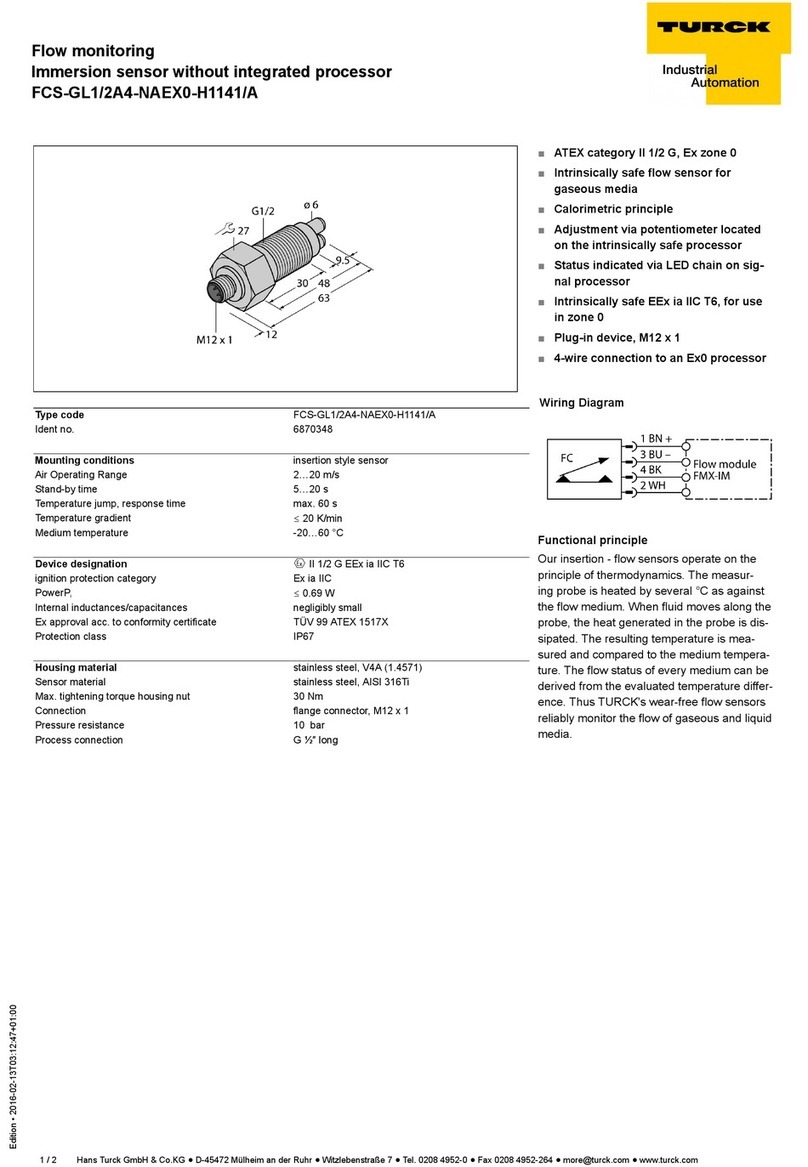

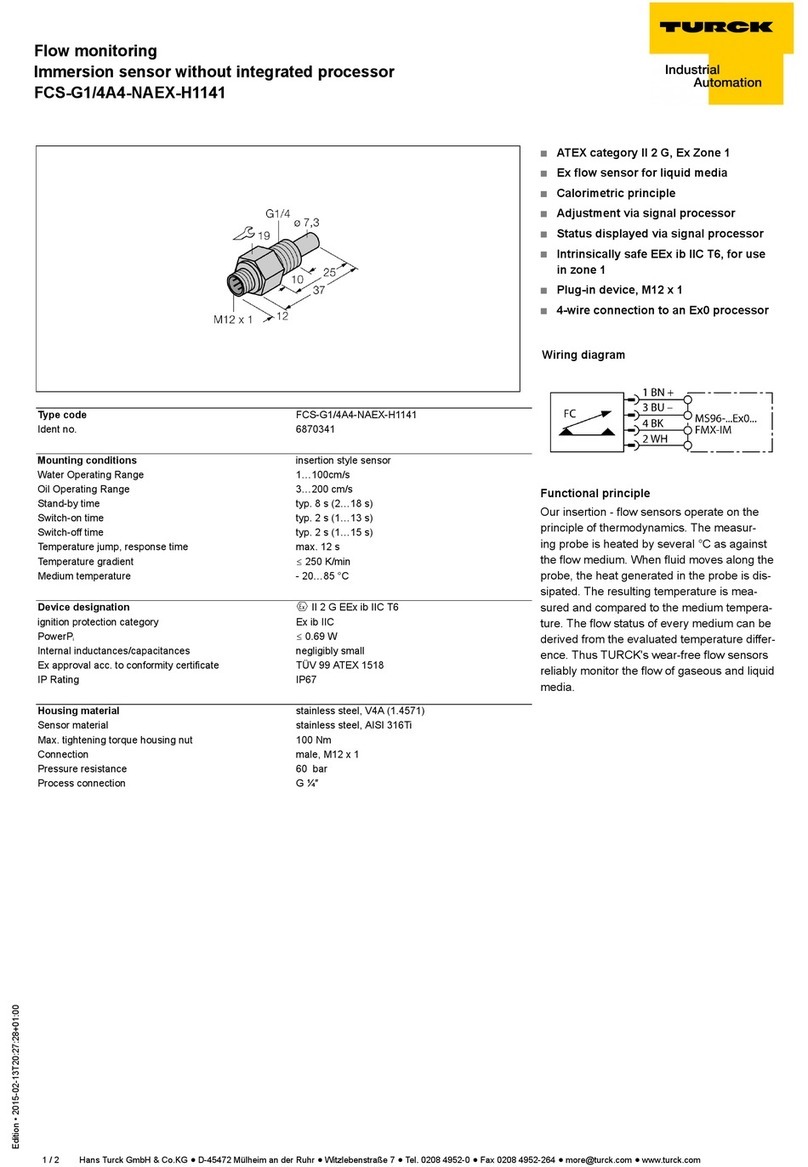

Flow monitoring

Immersion sensor without integrated processor

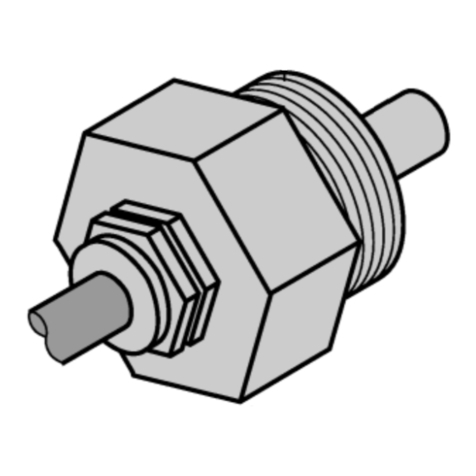

FCS-G1/2TN-NAEX

Edition • 2016-06-25T23:43:24+02:00

1 / 2

Hans Turck GmbH & Co.KG

ñ D-45472 Mülheim an der Ruhr

ñ Witzlebenstraße 7

ñ T

el. 0208 4952-0

ñ Fax 0208 4952-264

ñ [email protected] ñ www

.turck.com

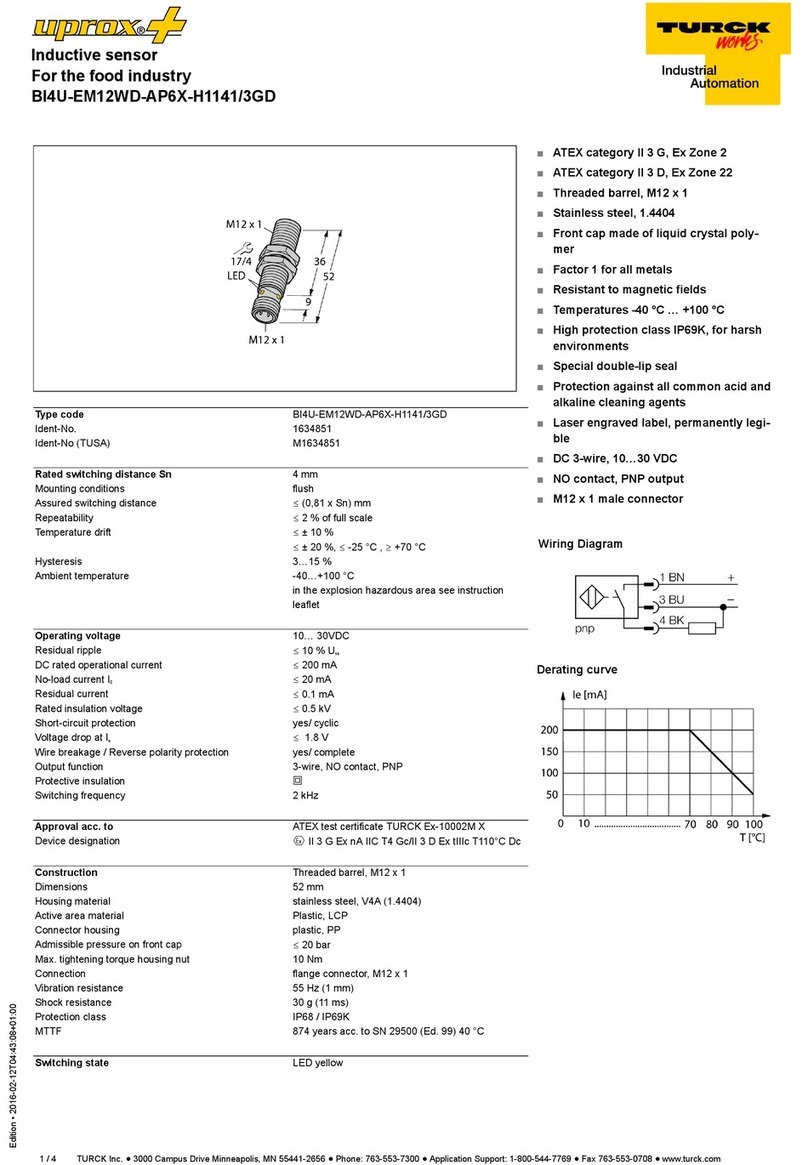

Type code FCS-G1/2TN-NAEX

Ident no. 6870312

Mounting conditions insertion style sensor

Water Operating Range 1…100cm/s

Oil Operating Range 3…200 cm/s

Stand-by time typ. 8 s (2…15 s)

Switch-on time typ. 2 s (1…13 s)

Switch-off time typ. 2 s (1…15 s)

Temperature jump, response time max. 12 s

Temperature gradient ð 250 K/min

Medium temperature -20…85 °C

Device designation É II 2 G EEx ib IIC T6

ignition protection category Ex ib IIC

PowerPið 0.69 W

Internal inductances/capacitances negligibly small

Ex approval acc. to conformity certificate TÜV 99 ATEX 1518

Protection class IP68

Housing material Metal, Titanium/Metal ceramics (3.7235)

Sensor material metal, Titanium/metal ceramic (3.7235)

Max. tightening torque housing nut 30 Nm

Connection PUR cable

Cable length 2 m

Cable cross section 4 x 0.25 mm2

Pressure resistance 60 bar

Process connection G ½″

■ATEX category II 2 G, Ex Zone 1

■Ex flow sensor for liquid media

■Calorimetric principle

■Adjustment via signal processor

■Status displayed via signal processor

■Sensor made of Titanium B3 with met-

al-ceramic coating

■EEx ib IIC T6 (use in zone 1)

■4-wire connection to EX0 processor

■Cable device

Wiring Diagram

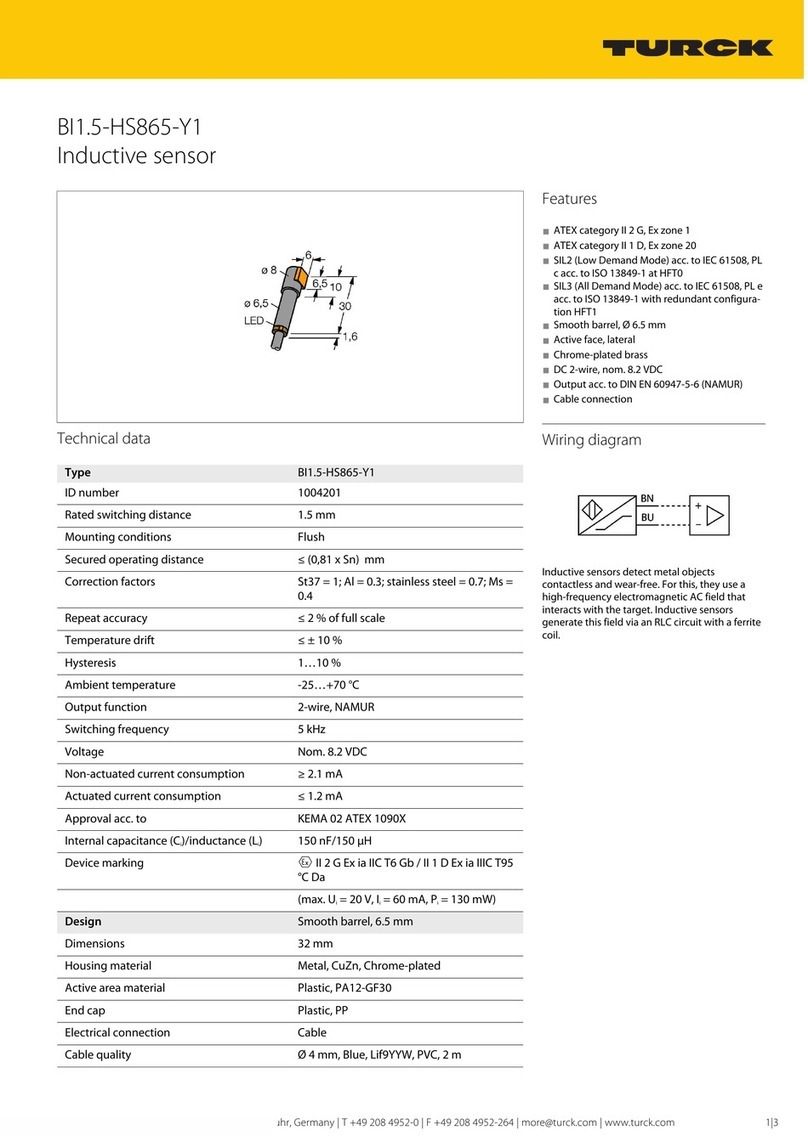

Functional principle

Our insertion - flow sensors operate on the

principle of thermodynamics. The measur-

ing probe is heated by several °C as against

the flow medium. When fluid moves along the

probe, the heat generated in the probe is dis-

sipated. The resulting temperature is mea-

sured and compared to the medium tempera-

ture. The flow status of every medium can be

derived from the evaluated temperature differ-

ence. Thus TURCK's wear-free flow sensors

reliably monitor the flow of gaseous and liquid

media.