V01.01 | 2019/05 3

Contents

1 About these Instructions................................................................................................................ 5

1.1 Target groups................................................................................................................ 5

1.2 Explanation of symbols used ..................................................................................... 5

1.3 Other documents ......................................................................................................... 5

1.4 Feedback about these instructions........................................................................... 5

2 Notes on the Product......................................................................................................................6

2.1 Product identification.................................................................................................. 6

2.2 Scope of delivery .......................................................................................................... 6

2.3 Legal requirements...................................................................................................... 6

2.4 Manufacturer and service........................................................................................... 6

3 For Your Safety................................................................................................................................. 7

3.1 Intended use.................................................................................................................. 7

3.2 General Safety Notes ................................................................................................... 7

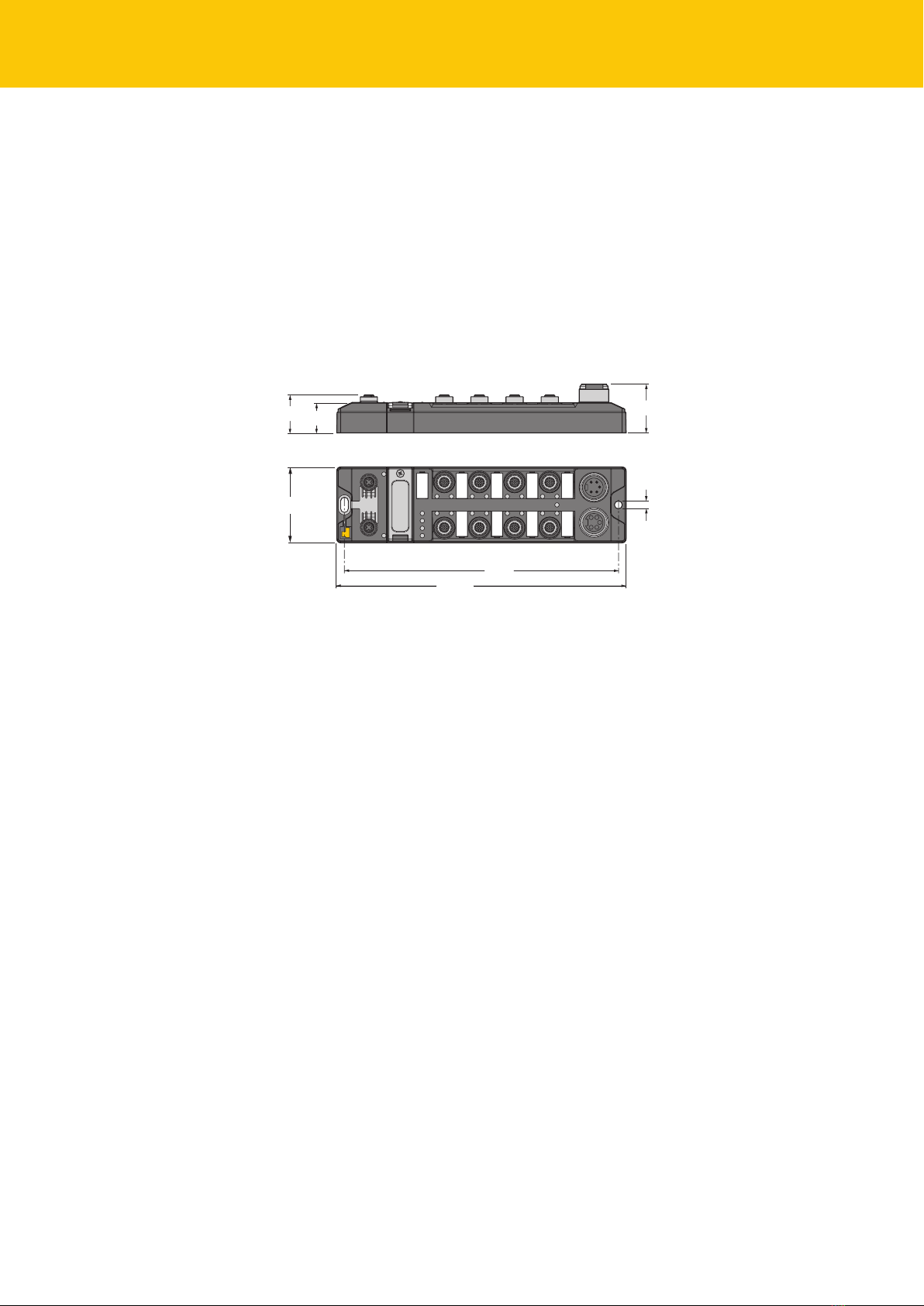

4 Product Description ........................................................................................................................ 8

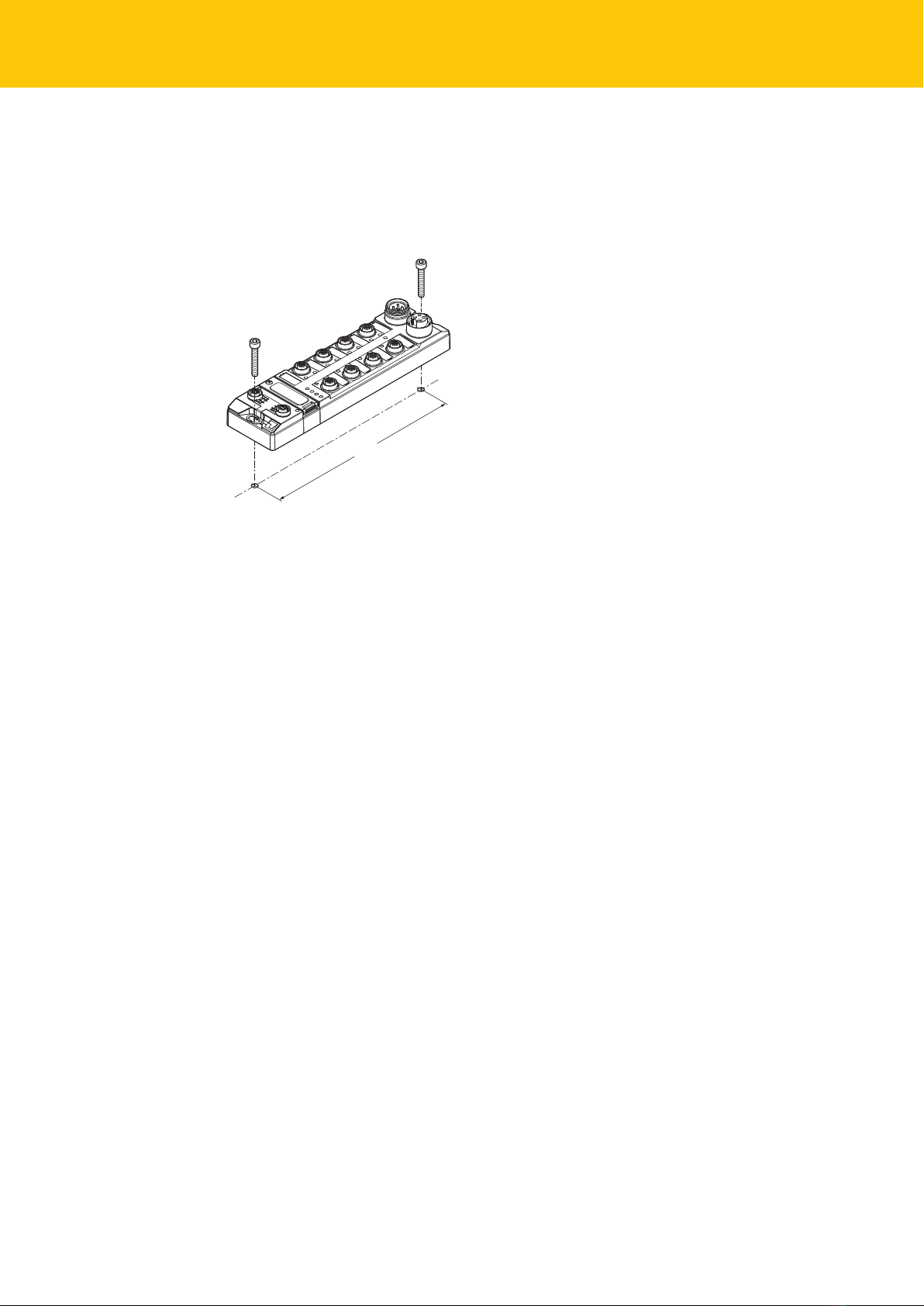

4.1 Device overview ........................................................................................................... 8

4.1.1 Operating elements .....................................................................................................................8

4.2 Properties and features............................................................................................... 8

4.3 Operating principle...................................................................................................... 9

4.4 Functions and operating modes ...............................................................................9

4.4.1 Linux distribution – Software components.........................................................................9

4.5 USB Host Port ................................................................................................................ 9

4.6 Technical Accessories .................................................................................................. 9

5 Mounting.........................................................................................................................................10

5.1 Mounting the device outdoors................................................................................10

5.2 Grounding the device................................................................................................11

5.2.1 Grounding and shielding concept....................................................................................... 11

5.2.2 Grounding the device (FG) ..................................................................................................... 12

6 Connection......................................................................................................................................13

6.1 Connecting the modules to Ethernet .....................................................................13

6.2 Connecting the power supply .................................................................................14

6.3 Connecting RFID read/write heads.........................................................................15

6.4 Connecting digital sensors and actuators.............................................................16

7 Commissioning ..............................................................................................................................17

7.1 Setting the IP address................................................................................................17

7.1.1 Setting the IP address via switches at the device........................................................... 17

7.1.2 Setting the IP address via the Turck Service Tool........................................................... 19

7.2 Programming RFID channels ...................................................................................20

7.2.1 GPIOs of the RFID channels – Overview ............................................................................ 21

7.2.2 Adapt slave controller via script ........................................................................................... 22

7.2.3 Programming RFID channels with Python 3.................................................................... 24

7.2.4 Programming RFID channels with Node.js....................................................................... 25

7.2.5 Programming RFID channels with C or C++ .................................................................... 26

7.3 Programming digital channels (DXP).....................................................................28

7.3.1 GPIOs of the DXP channels – Overview ............................................................................. 28