9

V01.01.01 | 2016/07

TX504E TX507/TX507E TX510 TX513

Weight 1 kg 1 kg 2.1 kg 2.8 kg

Fuse automatic

Hardware clock Clock/Calendar with back-up battery

Accuracy RTC (at 25°C) < 100 ppm

NOTE

For applications requiring compliance with EN 61131-2 and specifically in reference to 10 ms

voltage dips, the minimum power supply voltage is 18 VDC.

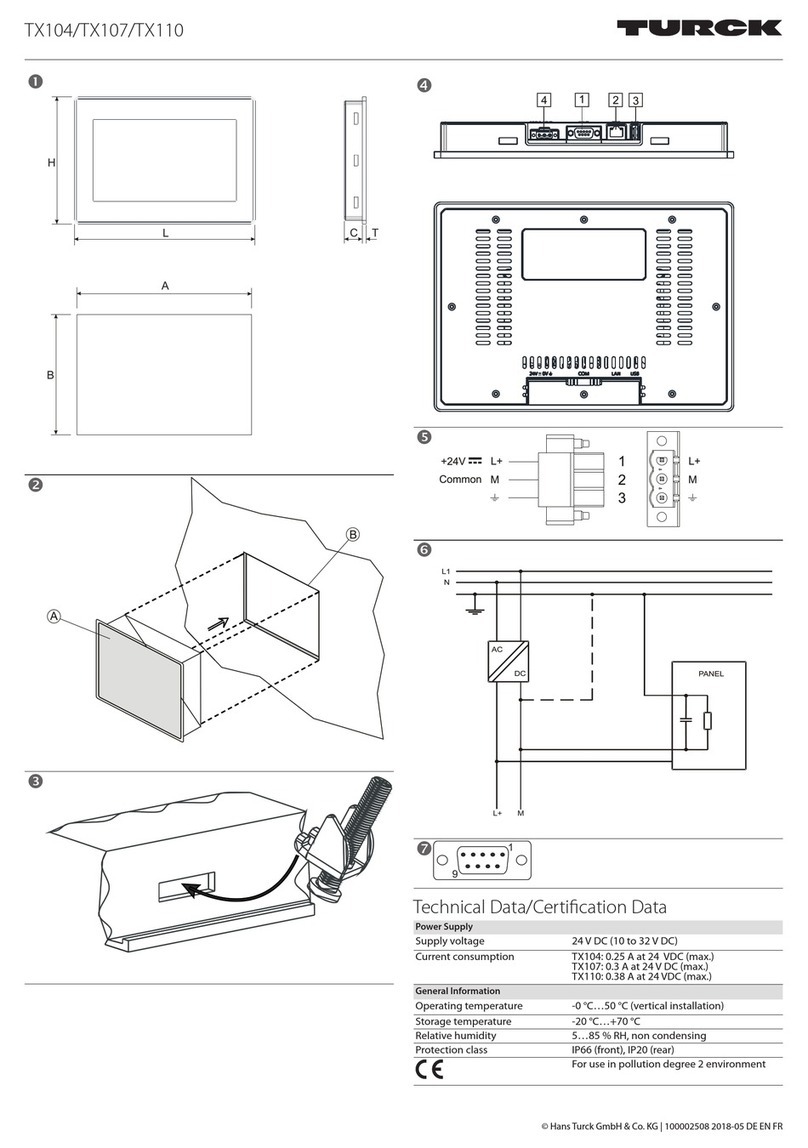

4.2 Environmental conditions/protection class

Environmental conditions

Operating temperature (surrounding air temperature) 0 to +50°C EN 60068-2-14

Storage temperature -20 to +70°C EN 60068-2-14

Operating and storage humidity 5 to 85 % RH non-condensing EN 60068-2-30

Vibrations 5 to 9 Hz, 7 mmp-p EN 60068-2-6

Shock 9 to 150 Hz, 1 g,

± 50 g, 11 ms, 3 pulses per axis

EN 60068-2-27

Protection class

Front panel IP66 EN 60529

NOTE

The front face of the unit, installed in a solid panel, has been tested using conditions

equivalent to the standards shown in the “Environmental conditions”. Even though the

level of resistance of the unit is equivalent to these standards, oils that should have no

effect on the TX500 can possibly harm the unit. This can occur in areas where either va-

porized oils are present, or where low viscosity cutting oil are allowed to adhere to the

unit for long periods of time. If the front face protection sheet on the TX500 is peeled

off or damaged, this may lead to the ingress of oil into the unit and separate protec-

tion measures are suggested.

If the installation gasket is used for a long period of time, or if the unit and its gasket

are removed from the mounting plate, the original level of the protection cannot be

guaranteed.

4.3 Electromagnetic Compatibility (EMC)/durability

Electromagnetic Compatibility (EMC)

Radiated disturbance test Class A EN 55011

Electrostatic discharge immunity test 8 kV (air electrostatic discharge) EN 61000-4-2

Radiated, radio-frequency,

electromagnetic field immunity test

80 MHz …1 GHz, 10 V/m

1,4 GHz … 2 GHz, 3 V/m

2 GHz … 2.7 GHz, 1 V/m

EN 61000-4-3

Burst immunity test ± 2 kV DC power port

± 1 kV signal line

EN 61000-4-4

Surge immunity test ± 0,5 kV DC power port (line to earth)

± 0,5 kV DC power port (line to line)

± 1 kV signal line (line to earth)

EN 61000-4-5