1

TABLE OF CONTENTS

Paragraph Page No.

1GENERAL................................................................................................................3

1.1 Manufacturer and US Official Correspondence Information......................3

1.2 Intended Use..................................................................................................3

1.3 Intended Users ..............................................................................................3

1.4 Incoming Inspection .....................................................................................3

1.5 Warranty........................................................................................................3

1.6 Warranty Statement ......................................................................................4

2TECHNICAL DATA................................................................................................5

2.1 Introduction ..................................................................................................5

2.2 Storage Conditions........................................................................................6

2.3 Operating Conditions....................................................................................6

2.4 Construction..................................................................................................6

2.5 Directives and Standards ..............................................................................7

2.6 Utilities ..........................................................................................................8

2.7 Waste Water Disposal ...................................................................................8

2.8 Environment Emission Information.............................................................8

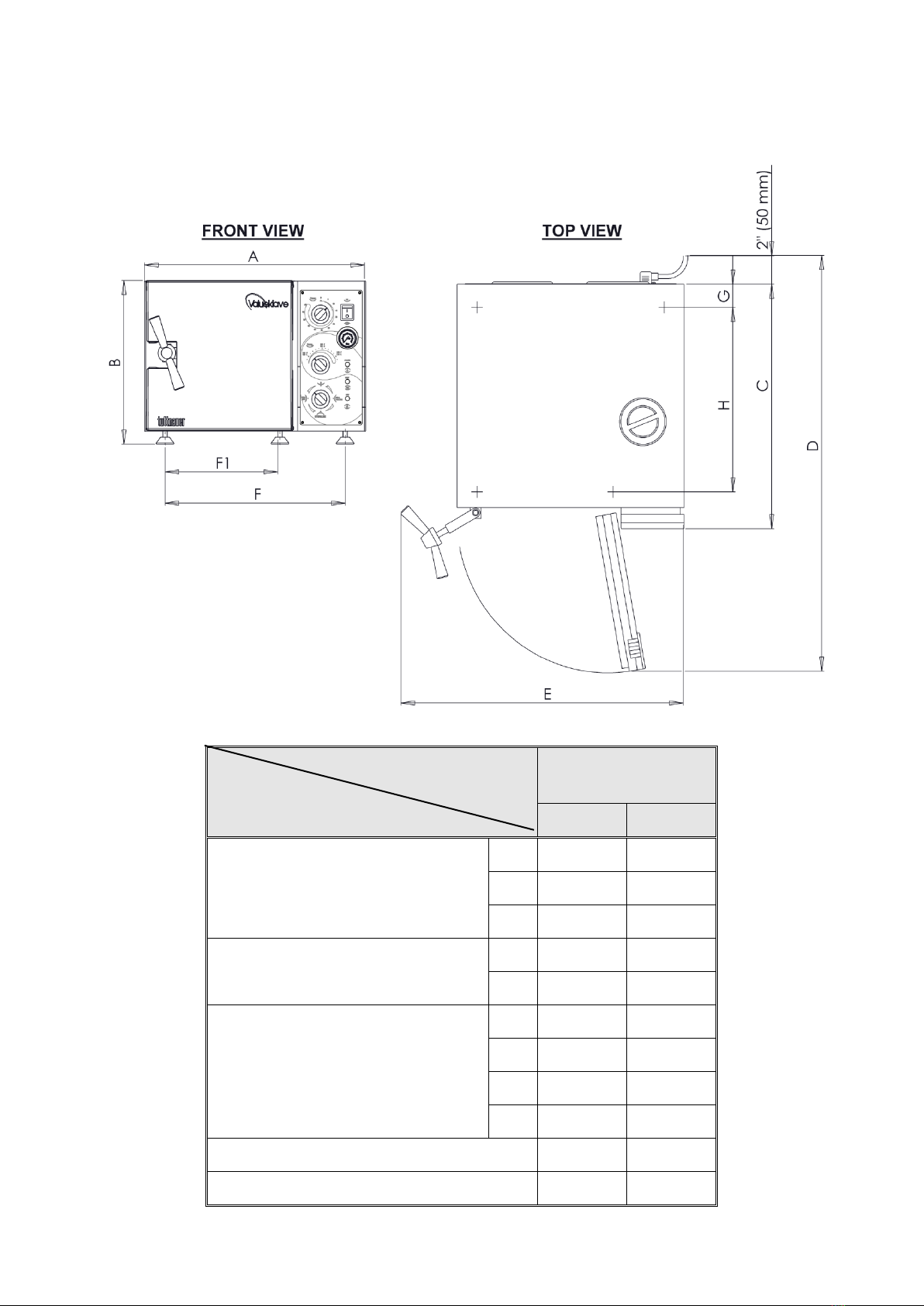

2.9 Dimensions, Models 1730 .............................................................................9

2.10 Dimensions, Models 2340, 2540 .................................................................10

2.11 Dimensions, Models 3140 ...........................................................................11

2.12 Dimensions, Models 3850, 3870 .................................................................12

2.13 Technical Specifications .............................................................................13

2.14 Electrical Data ............................................................................................14

2.15 Maximum Solid Load Sizes.........................................................................14

2.16 Symbols Description....................................................................................15

2.17 Water Quality ..............................................................................................17

3DESCRIPTION OF COMPONENTS....................................................................23

3.1 Control Panel ..............................................................................................23

3.2 Other Components ......................................................................................23

4INSTALLATION INSTRUCTIONS......................................................................24

4.1 Electrical .....................................................................................................24

4.2 Setup............................................................................................................24

4.3 Lifting and Carrying...................................................................................25

5PREPARATION BEFORE STERILIZATION .....................................................26

6OPERATION .........................................................................................................30

6.1 Loading and Unloading the Device ............................................................30

6.2 Fill the Water Reservoir..............................................................................30

6.3 Sterilization Time Table..............................................................................32

7SERVICE AND MAINTENANCE INSTRUCTIONS...........................................35

7.1 Preventive and Scheduled Maintenance.....................................................35

7.2 Draining the Reservoir................................................................................36

7.3 Cleaning the Air Jet....................................................................................37

7.4 Replacing the Door Gasket .........................................................................38

7.5 Checking the Safety Valve ..........................................................................39