TWIN BUSCH GmbH

Technical changes for purposes of a technical advancement as well as deviation in colour, errors and printing mistakes are reserved.

- 3 -

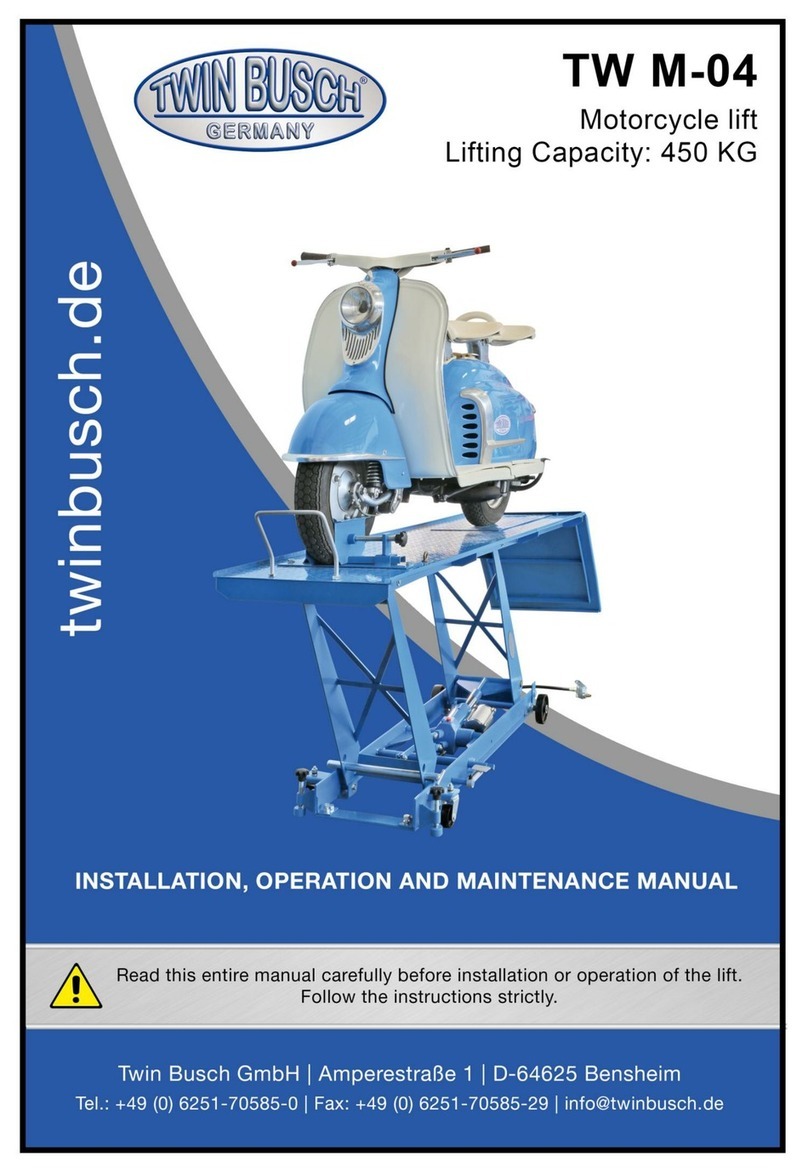

SCISSOR LIFT INSTRUCTION MANUAL

INDEX PAGE

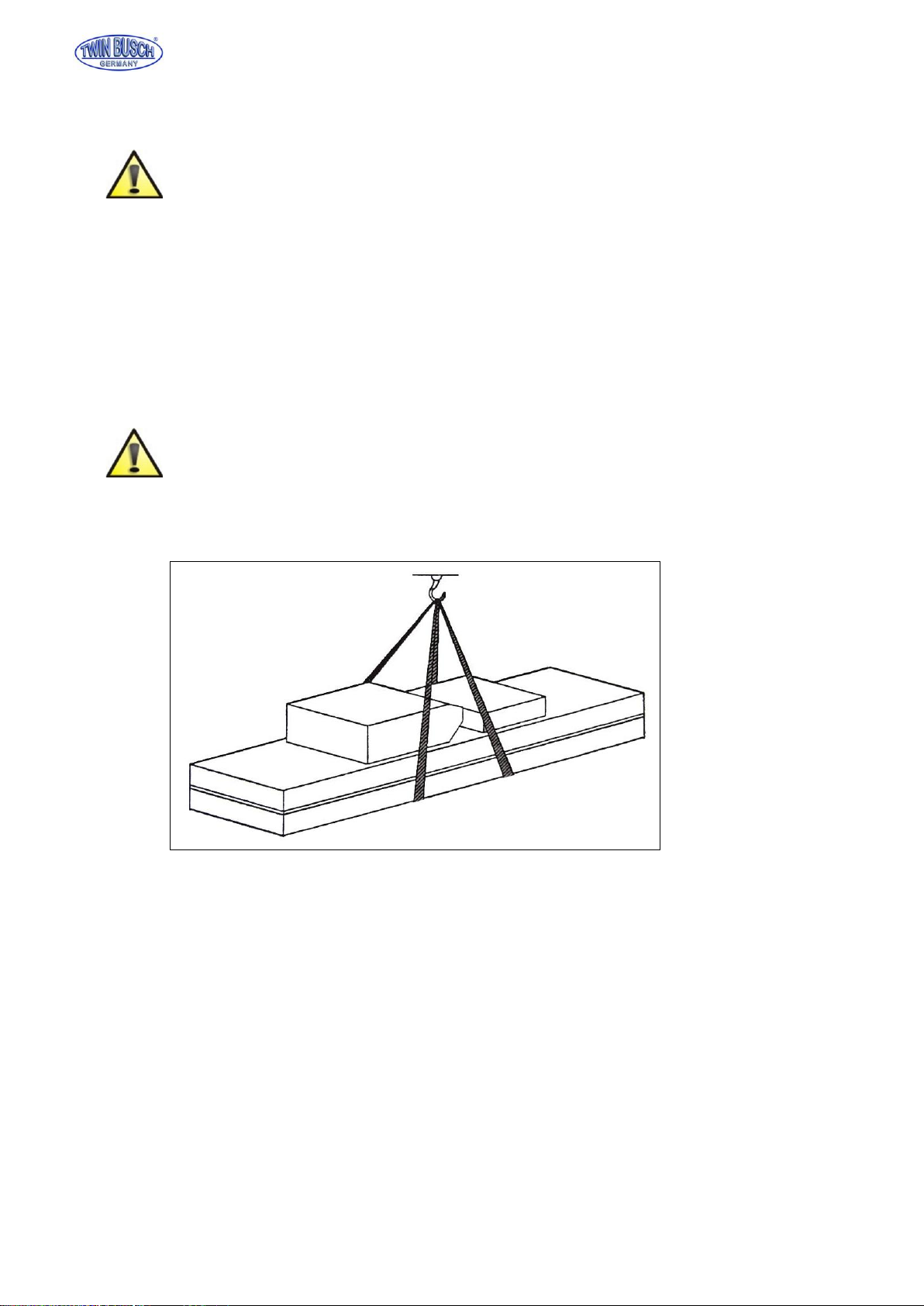

1. Packing, transport and storage......................................................................................................................- 4 -

1.1 Packing:................................................................................................................................................- 4 -

1.2 Transport:..............................................................................................................................................- 5 -

1.3 Storage:.................................................................................................................................................- 5 -

2. Manual introduction........................................................................................................................................- 6 -

3. Description of the machine.............................................................................................................................- 6 -

3.1 Machine Application..............................................................................................................................- 6 -

3.2 Structure Features.................................................................................................................................- 6 -

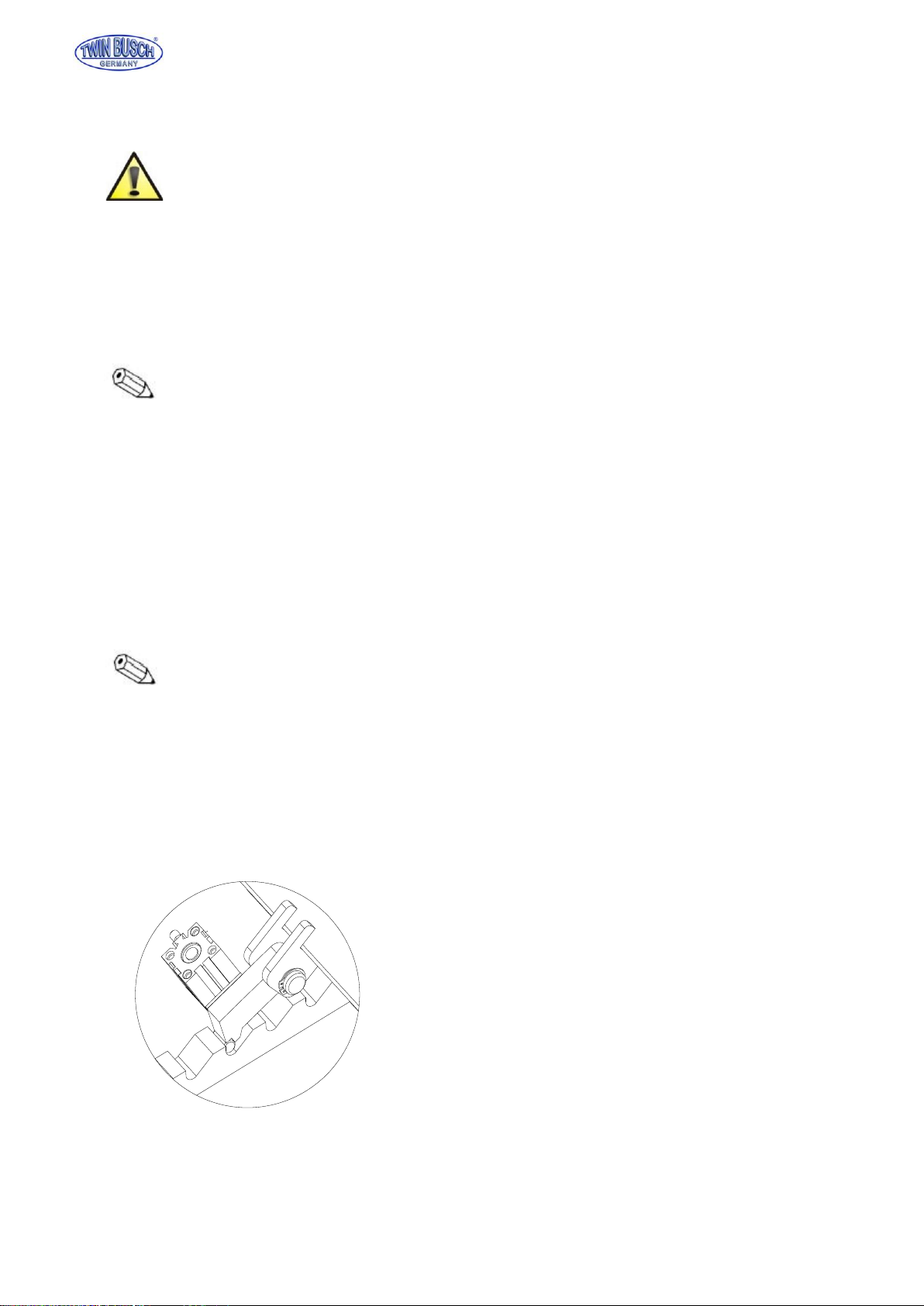

3.3 Safety lock structure..............................................................................................................................- 6 -

3.4 Equipment.............................................................................................................................................- 7 -

3.5 Frame....................................................................................................................................................- 7 -

3.6 Power unit.............................................................................................................................................- 7 -

4. Specifications.................................................................................................................................................- 8 -

4.1 Main technical parameter......................................................................................................................- 8 -

4.2 External dimension drawing..................................................................................................................- 9 -

5 Operation.....................................................................................................................................................- 10 -

6 Maintenance and care.................................................................................................................................. - 11 -

7 Circuit diagram............................................................................................................................................. - 11 -

8 Gas loop diagram......................................................................................................................................... - 11 -

9 Explosion drawing ....................................................................................................................................... - 11 -

10 Accessory packing list................................................................................................................................. - 11 -