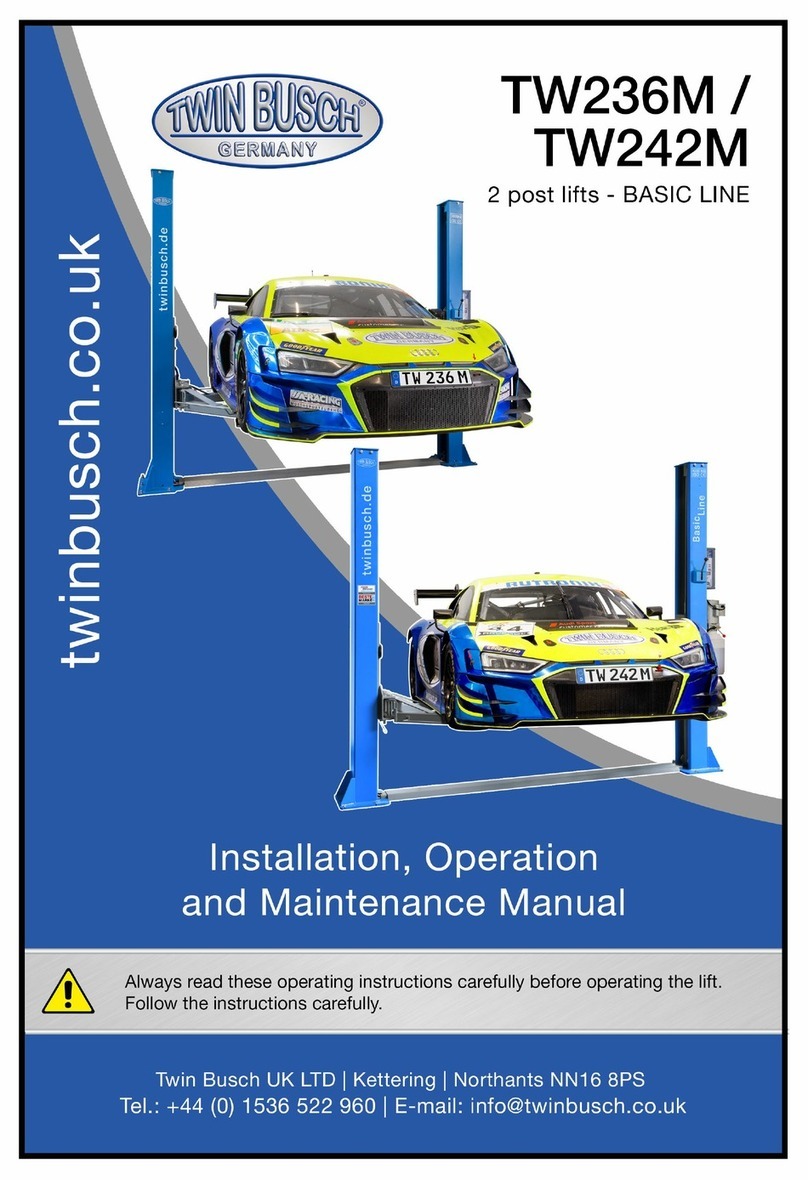

Manual of 2-post lift garage model TW242GE

TW242GE_2-post_lift_garage_model_manual_uk_00_20231206.pdf

Version: -00, 06.11.2023

Table of contents

1. General information ............................................................................................................................1

2. Identification of the instructions for use ...............................................................................................1

3. Technical data......................................................................................................................................1

4. Modification of the product .................................................................................................................1

5. Important notes / warnings..................................................................................................................2

5.1 Important note............................................................................................................................................2

5.2 Specialised personnel ..................................................................................................................................2

5.3 Safety instructions.......................................................................................................................................2

5.4 Safety devices..............................................................................................................................................3

5.5 Monitoring and testing the safety equipment.............................................................................................3

5.6 Warnings and symbols ................................................................................................................................4

5.7 Load distribution .........................................................................................................................................5

6. Compliance with the product ...............................................................................................................5

7. Technical specification .........................................................................................................................5

7.1General technical description......................................................................................................................5

7.2 Machine description....................................................................................................................................6

8. Installation ..........................................................................................................................................7

8.1 Before installation .......................................................................................................................................7

8.2 Precautions before installation....................................................................................................................7

8.3 Structure......................................................................................................................................................8

8.4 Checkpoints after installation....................................................................................................................15

9. Operating instructions .......................................................................................................................16

9.1 Safety precautions.....................................................................................................................................16

9.2 Flow chart .................................................................................................................................................16

9.3 Operating instructions (lifting and lowering process)................................................................................17

9.4 Description of the switch box (control box) ...............................................................................................17

10. Operating instructions .......................................................................................................................18

11. Maintenance .....................................................................................................................................19

11.1 Daily inspection of parts before operation ................................................................................................19

11.2 Weekly inspection of the parts ..................................................................................................................19

11.3 Monthly inspection of parts ......................................................................................................................19

11.4 Annual inspection of the parts ..................................................................................................................20

12. Behaviour in the event of an incident .................................................................................................20

13. Appendix ...........................................................................................................................................21