TFP425

Page 4 of 6

Copper sprinkler system piping

Any time copper piping is used in any

part of a fire sprinkler system, the

copper piping must be installed in con-

formance with all applicable standards

and requirements for copper piping,

including: NFPA 13, 13D, 13R and 25,

ASTM B 813, ASTM B 828, and Copper

Development Association (CDA). Any

soldering in any part of a sprinkler

system, either internally or externally,

must be done with use of only an

ASTM B 813 approved flux. Residual

flux must be thoroughly removed from

both the interior and exterior surfaces

of the piping before installing the sprin-

kler heads. The use of improper flux,

or the failure to thoroughly remove

proper flux, may result in corrosion of

the sprinkler head or stress cracking,

which in turn may cause the sprinkler

heads to develop leaks, operate unex-

pectedly, or not operate properly.

Installation

The TYCO RAPID RESPONSE Series

LFII Residential Flush Horizontal

Sidewall Sprinklers (TY2384) must

be installed in accordance with this

section:

General Instructions

The Protective Cap is to remain on the

sprinkler during installation until the

ceiling installation is complete. The

Protective Cap must be removed to

place the sprinkler in service.

A leak-tight 1/2 in. NPT sprinkler joint

Should be obtained by applying a

minimum to maximum torque of 7 to

14 lb-ft (9,5 to 19,0 N∙m). Higher levels

of torque can distort the sprinkler Inlet

with consequent leakage or impairment

of the sprinkler.

Do not attempt to compensate for

insufficient adjustment in the sprinkler

by under- or over-tightening the Sprin-

kler/Support Cup Assembly. Re-adjust

the position of the sprinkler fitting to

suit.

Each sprinkler must be inspected

before installation. Do not use any

sprinkler that exhibits any deformations

or cracks, including cracks on the pro-

tective cap.

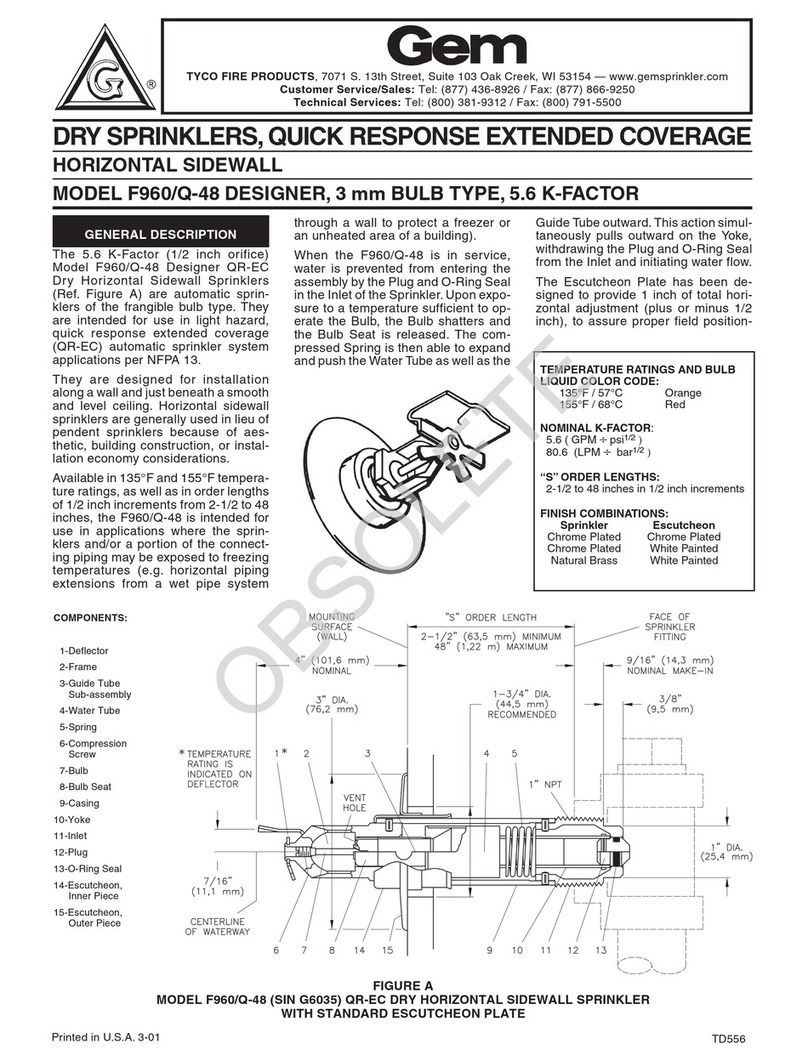

Step 1. Horizontal sidewall sprinklers

must be installed only in the horizontal

position with their centerline of water-

way perpendicular to the backwall and

parallel to the ceiling. The top of the

deector is to face towards the ceiling,

as depicted in Figure 1B, with the front

edge of the deector parallel to the

ceiling.

Step 2. Install the sprinkler tting so

that the distance from the face of the

tting to the mounting surface will be

nominally 3/4 in. (19,1 mm) as shown

in Figure 1A.

Step 3. With pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

tting.

Step 4. Wrench tighten the sprin-

kler using only the Sprinkler Socket

or Wrench & Socket Combination

(Ref. Figure 2). The wrench recess of

the socket is to be applied to the sprin-

kler wrenching area (Ref. Figure 1A).

The Sprinkler Wrench must be correctly

aligned to slide over the Protective Cap.

After the leading edge of the Sprinkler

Wrench passes over the flat portion of

the Protective Cap, it must be rotated

and realigned to engage with the sprin-

kler wrenching area.

Conversely to remove the Sprinkler

Wrench, sufficiently pull the Sprinkler

Wrench so that it disengages from the

sprinkler wrenching area, and then

rotate the Sprinkler Wrench so that it

can pass over the Protective Cap.

Step 5. Use the “backwall tolerance

limit” indicator (Ref. Figure 1A) on the

Protective Cap to check for proper

installation depth. The finished wall

surface must line up within the 3/16 in.

(4,8 mm) range of the “backwall tol-

erance limit”. Figure 1A illustrates the

finished wall surface at the mid-point

of the “backwall tolerance limit”. Relo-

cate the sprinkler fitting as necessary. If

desired the Protective Cap may also be

used to locate the center of the clear-

ance hole. Apply chalk to the center

point of the Cap and then gently touch

the wall material against the center

point of the Cap.

Step 6. After the wall has been com-

pleted with the 2-1/4 in. (57,2 mm)

diameter clearance hole, use the Pro-

tective Cap Removal Tool (Ref. Figure

3) to remove the Protective Cap and

then push on the Escutcheon until its

flange comes in contact with the wall.

If the Escutcheon cannot be engaged

sufficiently to contact the wall and/or

the Escutcheon cannot be engaged per

Figure 1C (i.e., 3/16 in. (4,8 mm) to flush

with respect to the face of the sprinkler

body), relocate the sprinkler fitting.

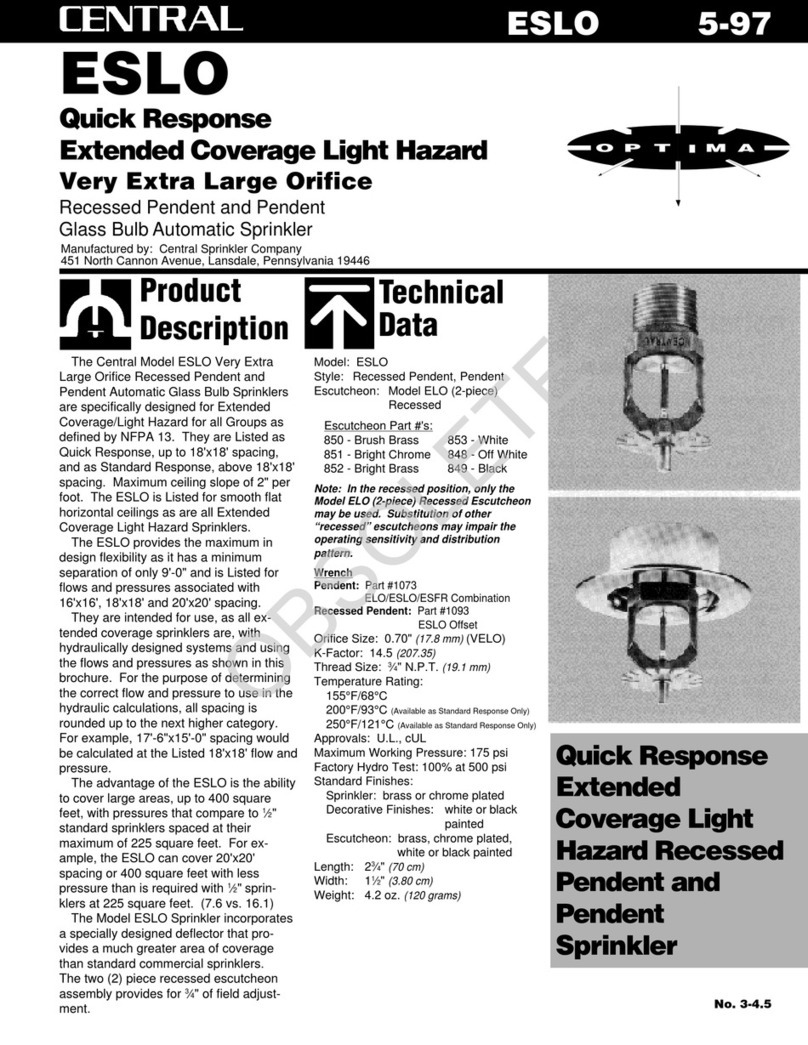

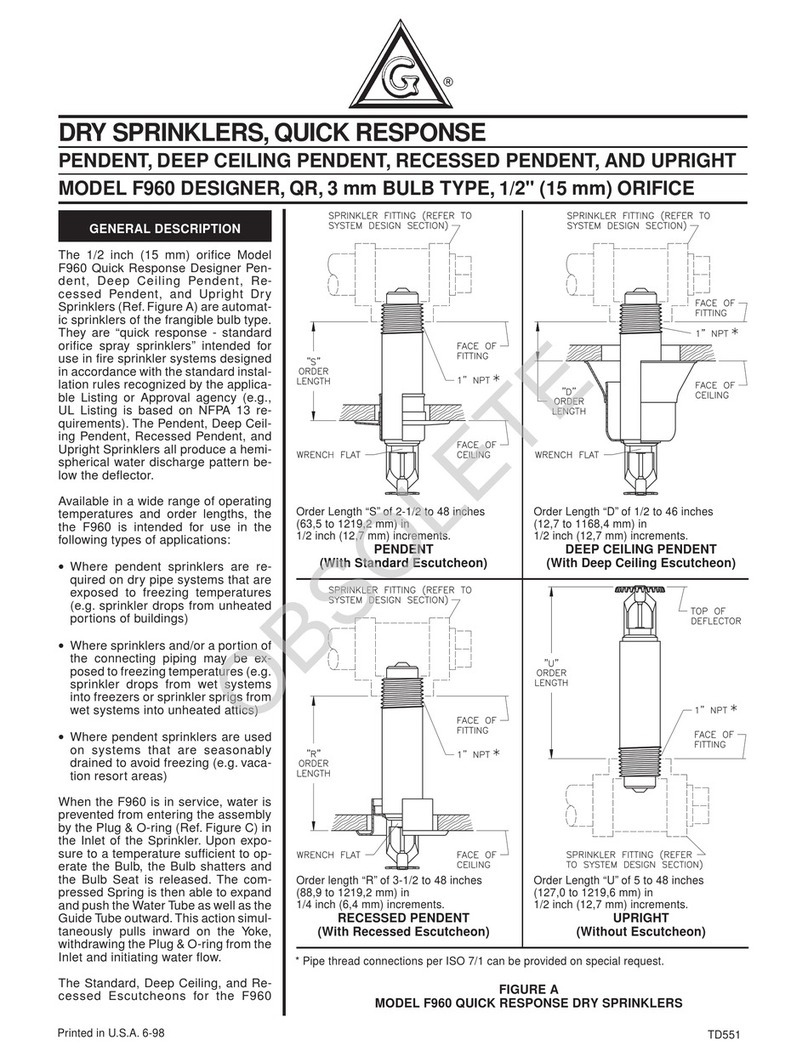

SOCKET

#4949

RECESS

ACCEPTS

3/8" SOCKET

DRIVE

#4950

WRENCH & SOCKET

COMBINATION

WRENCH

FIGURE 2

SPRINKLER SOCKET AND

WRENCH & SOCKET COMBINATION

FIGURE 3

PROTECTIVE CAP

REMOVAL TOOL