Type D3 PROTECTOSPRAY

Directional Spray Nozzles, Open,

Medium Velocity

Page 1 of 6 MARCH 2014 TFP802

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cau-

tions with respect to handling

and installation of sprinkler sys-

tems and components. Improp-

er handling and installation can

permanently damage a sprin-

kler system or its components

and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

General

Description

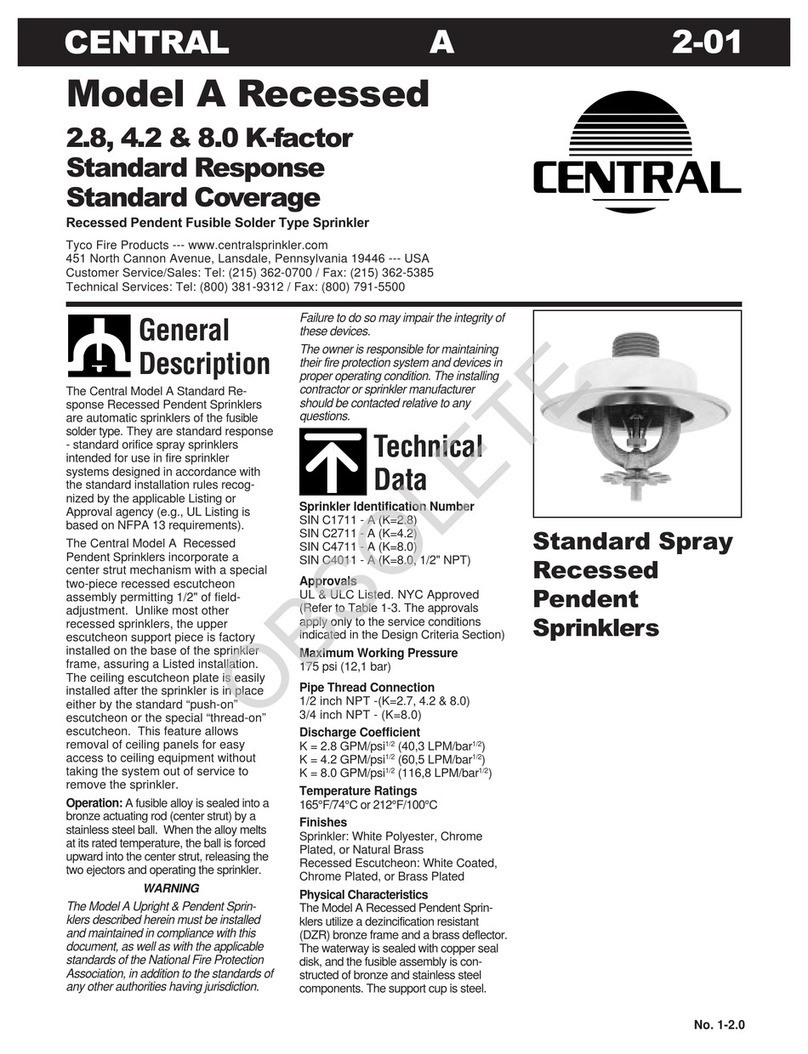

The TYCO Type D3 PROTECTO-

SPR AY Nozzles are open (non-auto-

matic) directional spray nozzles and

they are designed for use in water

spray xed systems for re protection

applications. They are external deec-

tor type nozzles that discharge a uni-

formly lled cone of medium velocity

water droplets.

The D3 Nozzles are effective in cov-

ering exposed vertical, horizontal,

curved, and irregular shaped surfaces

in a cooling spray to prevent exces-

sive absorption of heat from an exter-

nal re and possible structural dam-

age or spread of re to the protected

equipment. In some applications, de-

pending on water design density re-

quirements, the Type D3 Nozzles

may also be used for re control or

extinguishment.

The Type D3 Nozzles are available in a

wide variety of orice sizes and spray

angles (included angle of discharge)

to provide versatility in system design.

Refer to Technical Data Sheet TFP890

for information on Blow-Off Plugs that

can be used for applications where

protection is required against insect

infestation or accumulation of debris

within the nozzle orice.

It is recommended that the end user

be consulted with respect to the suit-

ability of the materials of construc-

tion and nish for any given corrosive

environment. The effects of ambient

temperature, concentration of chem-

icals, and gas/chemical velocity,

should be considered, at a minimum,

along with the corrosive nature to

which the sprinklers may be exposed.

The Type D3 PROTECTOSPRAY Noz-

zle is a re-designation for the Gem

Type D3.

NOTICE

The Type D3 PROTECTOSPRAY Noz-

zles described herein must be in-

stalled and maintained in compliance

with this document, and with the ap-

plicable standards of the National Fire

Protection Association, in addition to

the standards of any authorities having

jurisdiction. Failure to do so may im-

pair the performance of these devices.

The design of individual water spray

fixed systems can vary considerably,

depending on the characteristics and

nature of the hazard, the basic pur-

pose of the spraying system, the con-

figuration of the hazard, and wind/

draft conditions. Because of these

variations as well as the wide range of

available nozzle spray characteristics,

the design of water spray fixed sys-

tems for fire protection must only be

performed by experienced designers

who thoroughly understand the limi-

tations as well as capabilities of such

systems.

The owner is responsible for maintain-

ing their fire protection system and

devices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

Technical

Data

Approvals

The natural nish, chrome plated, and

lead coated bronze, as well as stain-

less steel Type D3 PROTECTOSPRAY

Nozzles are UL and C-UL Listed, as

well as FM Approved.

Maximum Working Pressure

175 psi (12,1 bar)

Also refer to Figure 2, Note 2

Discharge Coefficient

Refer to Table A

Spray Angles

Refer to Table B

Finish and Material

Refer to Table E

Thread Connection

1/2 inch NPT

Physical Characteristics

(Bronze)

Frame ............................Bronze

Deector..........................Bronze

Splitter ...........................Bronze

Pin ..............................Bronze

Physical Characteristics

(Stainless Steel)

Frame ........................ASTM A-74 3

Grade CF-8M (equiv. Type 316 S.S.)

Deector.....................Type 316 S.S.

Splitter ......................Type 316 S.S.

Pin .........................Type 316 S.S.