INSTALLATION MANUAL

1) GENERAL INFORMATION

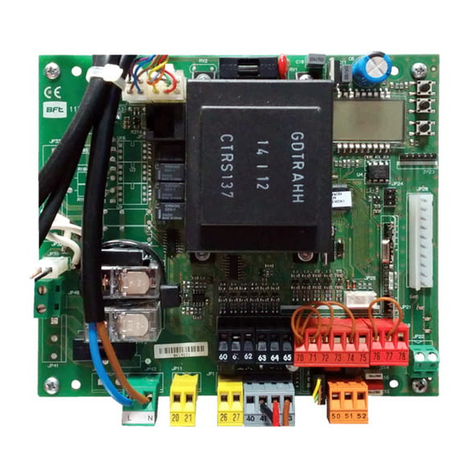

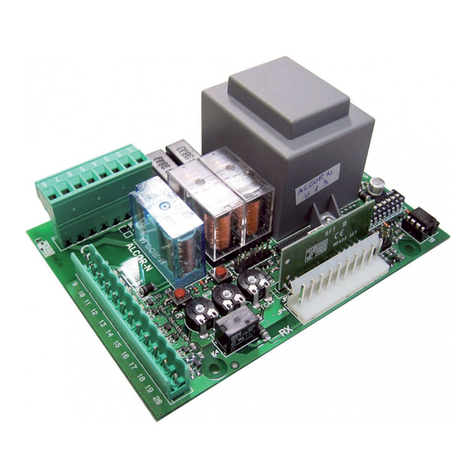

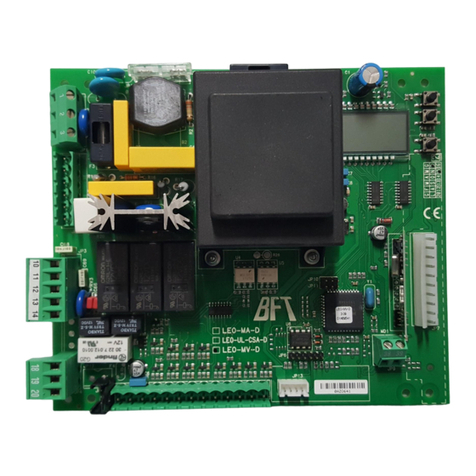

The ALCOR AC A control panel comes with standard factory settings.

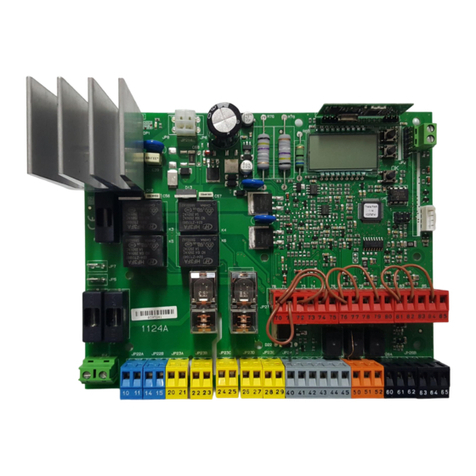

Any change must be set by means of the TRIMMER and DIP SWITCH settings.

Its main features are:

- Checking of 2 single phase motors

- Separate inputs for safeties

- Rolling-code in-built radio receiver.

The board has a terminal strip of the removable kind to make maintenance or re-

placementeasier.Itcomeswithaseriesofprewiredjumperstomaketheinstaller’s

job on site easier. The jumpers concern terminals: 70-71, 70-72, 70-74. If the

above-mentioned terminals are being used, remove the relevant jumpers.

TESTING

The ALCOR AC A panel controls (checks) the start relays and safety devices

(photocells) before performing each opening and closing cycle.

If there is a malfunction, make sure that the connected devices are working

properly and check the wiring.

2) TECHNICAL SPECIFICATIONS

Power supply 110-120V 50/60Hz

220-230V 50/60 Hz

Panel dimensions Fig. F

Low voltage/mains insulation > 2MOhm 500V

Operating temperature range -20 / +50°C

Dielectric rigidity mains/LV 3750V~ for 1 minute

Accessories power supply 4V~ (demand max. 0,2A)

AUX 0 - Flashing

Contact powered

120V~ 40W max

230V~ 40W max

Fuses Fig. C

Built-in Rolling-Code

radio-receiver frequency 433.92MHz

Setting of parameters and logics TRIMMER + DIP SWITCH

Max. n° of remotes that can be

memorized 63

Maximum power 750W

Maximum work time 90s

Usable transmitter versions:

All ROLLING CODE transmitters compatible with .

3) TUBE ARRANGEMENT Fig. A

Install the electrical system referring to the standards in force for electrical systems

CEI 64-8, IEC 364, harmonization document HD 384 and other national standards.

4) TERMINAL BOARD WIRING Fig. C

For the electric diagram and the cross section of the cables refer to the

manual of the actuator.

Once suitable electric cables have been run through the raceways and the auto-

mated device’s various components have been fastened at the predetermined

points,thenext stepistoconnectthem asdirectedand illustratedinthe diagrams

containedin therelevantinstruction manuals.Connect thelive, neutral andearth

wire (compulsory).

WARNINGS - When performing wiring and installation, refer to the standards

in force and, whatever the case, apply good practice principles. Wires carrying

dierent voltages must be kept physically separate from each other, or they must

be suitably insulated with at least 1mm of additional insulation.

Wires must be secured with additional fastening near the terminals, using devi-

ces such as cable clamps. All connecting cables must be kept far enough away

from dissipaters.

WARNING! For connection to the mains power supply, use a multicore cable

with a cross-sectional area of at least 3x1.5mm2of the kind provided for by

the regulations in force.

To connect the motors, use a cable with a cross-sectional area of at least

1.5mm2of the kind provided for by the regulations in force.

The cable must be type H05RN-F at least.

5) SAFETY DEVICES

Note: only use receiving safety devices with free changeover contact.

5.1) TESTED DEVICES Fig.G

5

.2)CONNECTION OF 1 PAIR OF NON-TESTED PHOTOCELLS FIG. B

WARNING!

The values of the impact force according to EN 12453 are only observed with

the use of safety edges (active) connected to the board.

6)MEMORIZING TRANSMITTERS FIG. D

7) REVERSING THE OPENING DIRECTION (Fig.E)

8)ADJUSTMENT PROCEDURE

-Before turning the unit on, check electrical connections.

- Set the following parameters:

Automatic Closing Time,

Phase shift timing while closing

- Set the logics.

WARNING! Incorrect settings can result in damage to property and injury

to people and animals.

WARNING: Check that the force of impact measured at the points pro-

vided for by standard EN 12445 is lower than the value laid down by

standard EN 12453.

KEYS

KEYS Description

S1 Add Start Key

associates the desired key with the Start command.

S2 Add Pedestrian Key

associates the desired key with the pedestrian command.

S2

>5s Conrms the changes made to parameter settings and operating

S1+S2

>10s Erase List

WARNING! Erases all memorized transmitters from the

receiver’s memory.

LED INDICATORS:

POWER Steadily lit: - Mains power on - Board powered - Fuses intact

START Lit: START input activated

OPEN Lit: OPEN pedestrian input activated

STOP Unlit: STOP input activated

PHOT Unlit: PHOT photocell input activated

FAULT 1 PHOT input safety device test input diagnostics

BAR Unlit: BAR safety edge input activated

FAULT 2 BAR input safety device test input diagnostics

ERR Unlit: no error

LIT: see error diagnostics table

RADIO

(GREEN)

Unlit: remote programming not active

Radio LED only ashing: Remote programming active, waiting for

hidden key.

Flashing in sync with Set LED: Transmitter deletion in progress

Lit: remote programming active, waiting for desired key.

Lit 1s: Radio receiver channel activated

SET Lit: see error diagnostics table

Flashing in sync with Radio LED: Transmitter deletion in progress

TABLE ERR

Led ERR

Lit slow ashing fast ashing

Led SET

Unlit

Photocell test,

Costa o Costa 8k2

failed

- Check photocell

connection and/

or logic settings

Lit

Reverse due to

obstacle - Ampe-

rostop

- Check for obsta-

cles in path

slow

ashing

Test hardware

card error

- Check the

connection to the

motor

- Hardware pro-

blems to the card

(contact technical

assistance)

Changed settings

and/or Operating

logics press S2 for

5s to conrm.

8 - ALCOR AC A

D814011 00100_02