VLC-800MX

17A-03-VLC

4 12/08

PAG E 4 of 18

2.1 SCOPE OF THIS DOCUMENT

This manual provides instructions on how to install,

commission and operate the VESDA VLC-800MX. It outlines

the standard pipe configurations permissible, power supply

requirements, and some installation tips. It does not provide

information on how to design and verify customised pipe work

configurations using the VESDA ASPIRE II pipe modelling

software and does not include detailed step-by-step installation

instructions.

This document provides brief details on how VSC (VESDA

System Configurator) is used to configure the detector. It does

not describe how to use VESDA VSC PC based software to

configure custom alarm thresholds, interrogate event logs and

smoke trends stored in the detector, set the internal clock and

generally access the extensive features of the LaserCOMPACT

detector.

This document is intended for proficient installation engineers

who are familiar with the commissioning of an MX Fire

Detection System but have limited experience with the

installation of VESDA Aspirating Smoke Detectors.

3. OPERATION

In normal operation, the VLC-800MX is polled every 5

seconds for the current smoke reading. This is scaled such that

a zero reading is reported as 12 and a measurement equating

the Fire threshold configured in the VLC is reported as 112. If

the value exceeds 112 for three consecutive polls, the MX

panel reports the condition as an alarm and commands the Fire

LED on the VLC to illuminate. A value exceeding 82 may be

reported as a Pre-alarm condition by the MX panel. In addition

to the poll every 5 seconds, the MX panel also polls the VLC

for its fault status every 20 seconds.

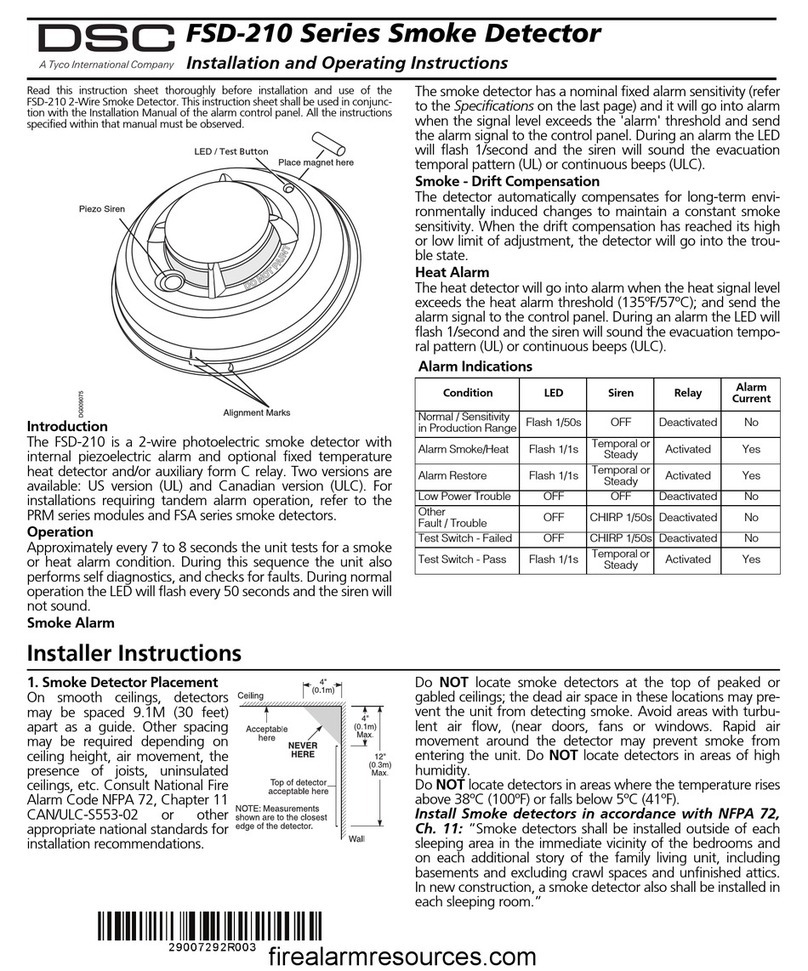

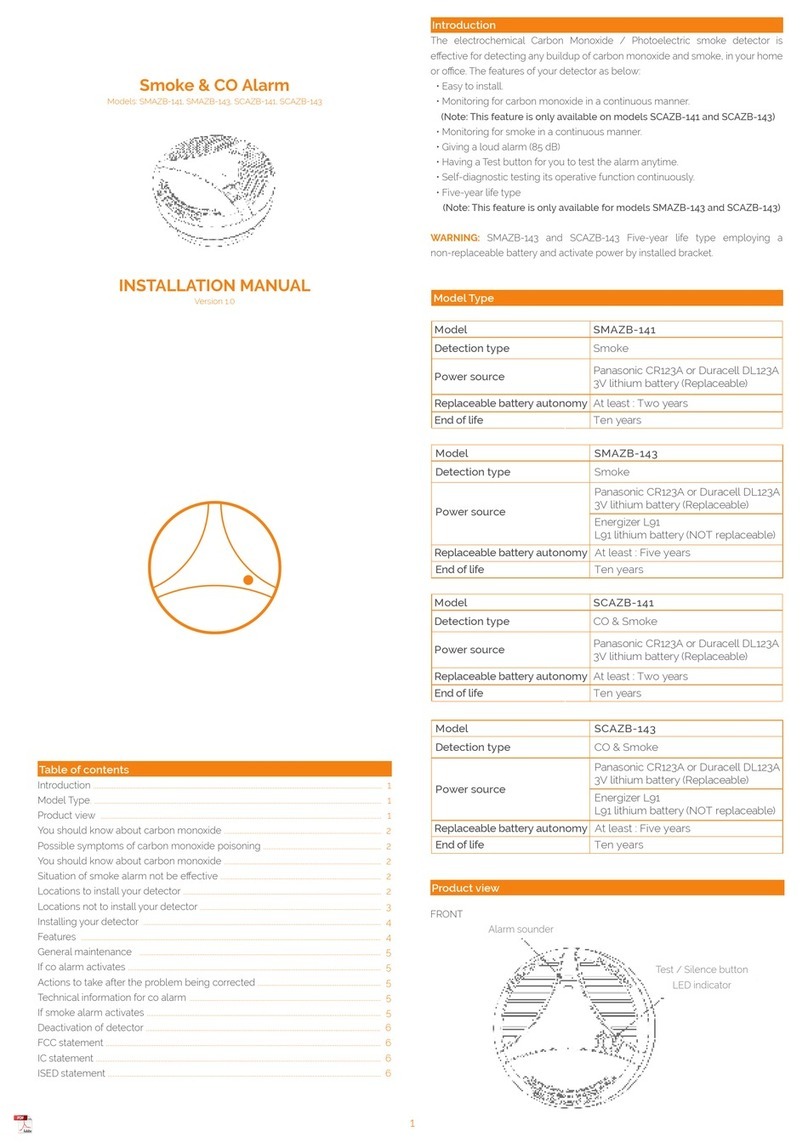

3.1 LED OPERATION

Fig. 4 refers.

LaserCOMPACT

VLC-800 MX

tyco

FILTER

OK

FAULT

SERVICE

FIRE

MX TECHNOLOGY

Red FIRE LED: Indicates that a fire condition

has been detected. Also, when

configured to flash-when-polled1,

it will normally flash once

every 5 seconds with a double

flash every 20 seconds

reflecting the polling

for smoke and fault.

Yel low SERVICE LED:Indicates that all the fault

conditions present are

likely to be resolved by a

technician with the aid of

VSC. If this LED is not

illuminated when the Fault

LED is, then it is likely that the

fault present will require a

change of component and it is

therefore recommended that the

Technician responding to the

call carries a spare detector with

him. The intention of this LED

is to eliminate the need for a

double service visit.

Yel low FAULT LED: Indicates that there is a fault

condition present which may

impair the detector’s ability to

detect smoke. Urgent attention

is required.

Note: Note that if the Service LED is also illuminated

then all the faults present are likely to be resolved

by a technician with the aid of VSC.

Green OK LED: Indicates that the operation is

normal. However, when the unit

is normalizing airflow this LED

flashes twice and when running

Autolearn this LED flashes

three times.

Yel low FILTER LED: Indicates that there is a problem

with the filter. It is

recommended that technicians

responding to such a fault carry

a spare filter cartridge.

1Some approvals bodies - notably VdS and SSL do not allow

the flash-when-polled option