Table of Contents

Pre-installation Information ..................................1

Before You Begin... ......................................1

Always Check the Gate’s Action ............................1

Gate Operator Classications ..............................1

Approved Obstruction Detection Devices .....................1

Safety Information and Warnings .............................1

Regulatory Warnings.....................................1

Wiring Specications .......................................2

AC Power Wiring ........................................2

DC Control and Accessory Wiring ...........................2

Mounting Pad Installation....................................3

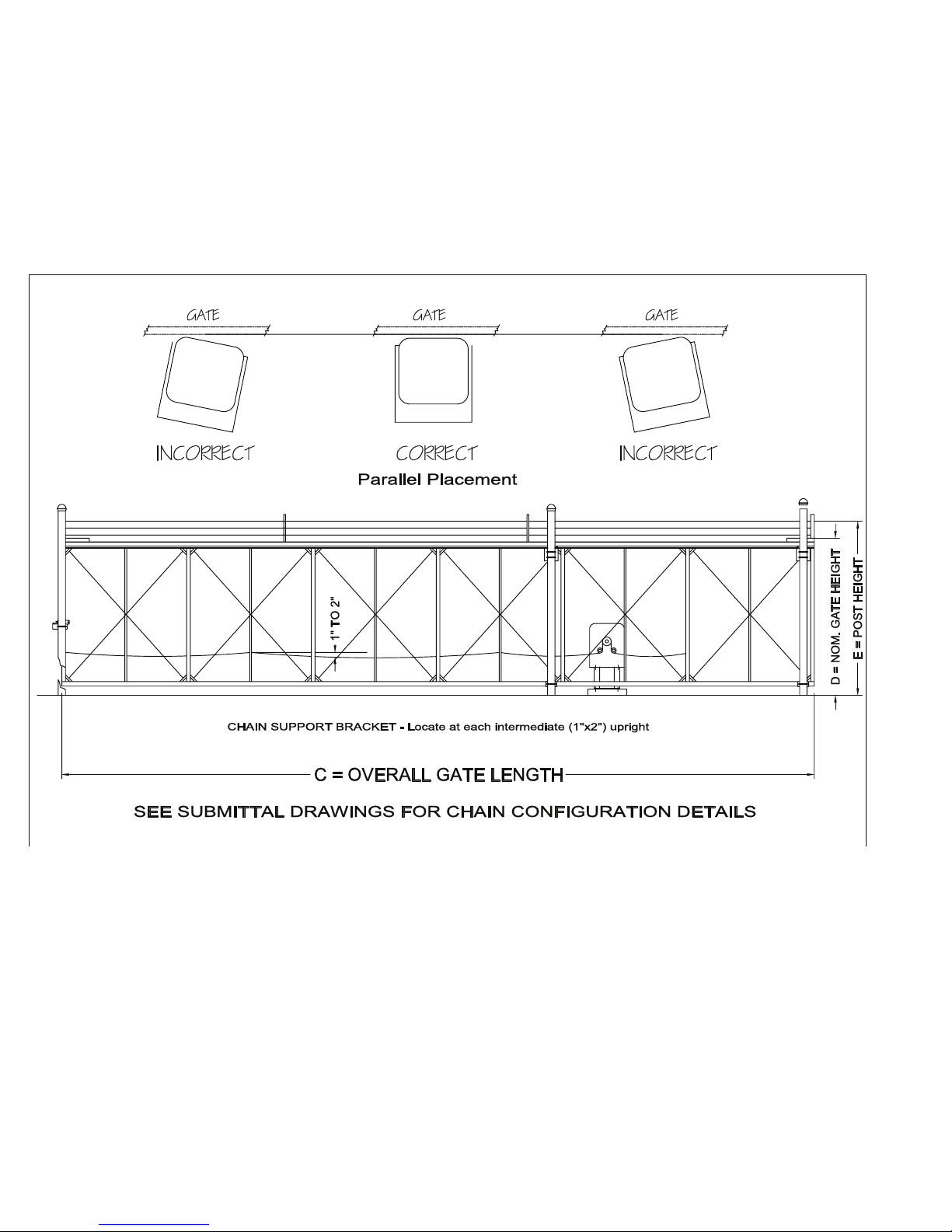

Gate Preparation ........................................3

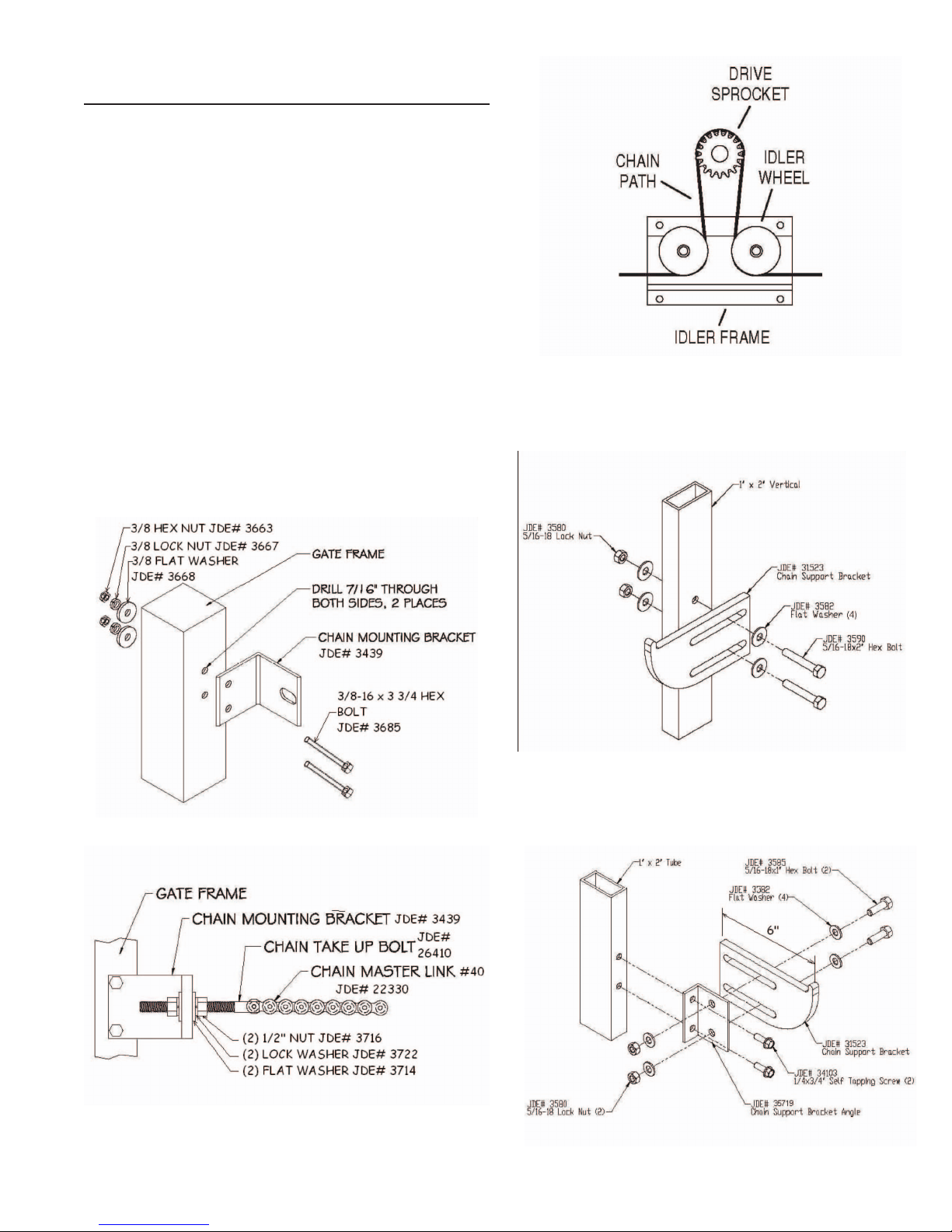

Gate Bracket and Chain Assembly ............................5

Operator Preparation .......................................6

Vent Plug Installation.....................................6

Operator Setup ............................................6

Controller Access .......................................6

AC Power Connection ....................................6

Earth Ground...........................................6

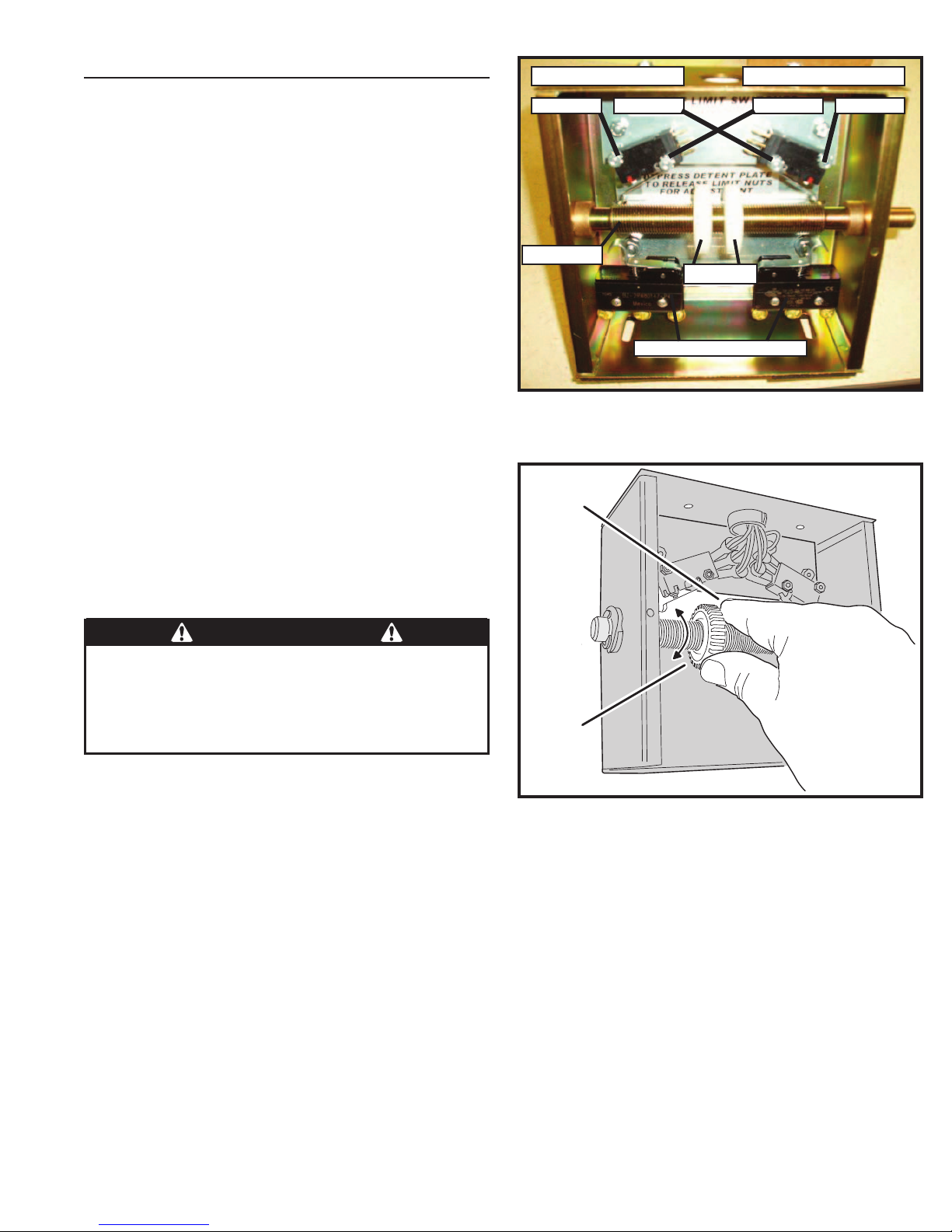

Limit Nuts Rough Adjustment ..............................7

Limit Nuts Fine Adjustment ................................7

Controller Features .........................................8

Indicator Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Terminal Descriptions ......................................10

Operator Accessory Connections ............................11

Basic Controller Programming ..............................12

Programming Overview..................................12

Entering Programming Mode .............................12

Exiting Programming Mode ...............................12

Programming Keystrokes ................................12

Left or Right Hand Operation .............................12

Dual Gate Enable ......................................12

Auto Close Timer.......................................12

Run Alarm and Pre-start Alarm ............................13

Maximum Open Direction Current Setting....................13

Maximum Close Direction Current Setting ...................13

Advanced Controller Programming...........................14

Entering Advanced Programming Mode .....................14

Maximum Run Time ....................................14

Single Button Input Setup ................................14

Stagger Mode (Rarely used in slide gate installations) ..........14

Stagger Delay Time (Rarely used in slide gate installations) .....15

Auxiliary Relay Mode....................................15

Reverse Delay Time ....................................15

Reset Cycle Count .....................................16

Maintenance Alert Trigger ................................16

Mid-travel Stop Position .................................16

Motor Type Selection....................................16

Radio Enable..........................................17

Antenna Installation.....................................17

Radio Transmitter Learn .................................17

Radio Transmitter Delete.................................17

MGT Obstacle Transmitter Learn ..........................17

MGT Obstacle Transmitter Delete ..........................17

Reset Controller to Factory Defaults ........................17

APeX v 1.4 Quick Programming Guide ........................18

Loop Layout Illustration ....................................20

Loop Detector Operating Instructions.........................21

Using Gate Reversing Edge Transmitters......................23

Reversing Edge Layout Illustration ...........................24

Photoeye Installation Illustration.............................25

Picket Gate Installation.....................................26

Dual Gate Installations .....................................27

Gate Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Open Button ..........................................28

Close Button ..........................................28

Stop Button ...........................................28

Single Input ...........................................28

Fire Department Input ...................................28

Fire Department Access .................................28

Open Input............................................28

Open Obstruction ......................................28

Close Obstruction ......................................28

Reverse Input .........................................28

Open Loop............................................28

Reverse Loop .........................................28

Shadow/reset Loop .....................................28

Operation Indications ......................................29

Power-up Display ......................................29

Idle Condition .........................................29

Last Gate Position/Condition..............................29

Pre-start Delay ........................................29

Reverse Delay.........................................29

Run Timer ............................................29

Error Indications ..........................................29

Entrapment ...........................................29

COMM LINK Connection Failure...........................29

MGT Obstacle Transmitter Trouble .........................29

Maximum Run Time Exceeded ............................29

Troubleshooting ..........................................30

Contacting Technical Support .............................30

Operator fails to start....................................30

Motor operates, but gate does not move.....................30

Motor sounds like it is working harder than normal .............30

Limit switch getting out of time ............................30

Gate stopping part way open or closed

(but no visible obstruction) ...............................30

Gate staying open with automatic system....................30

How to Order Replacement Parts ..........................30

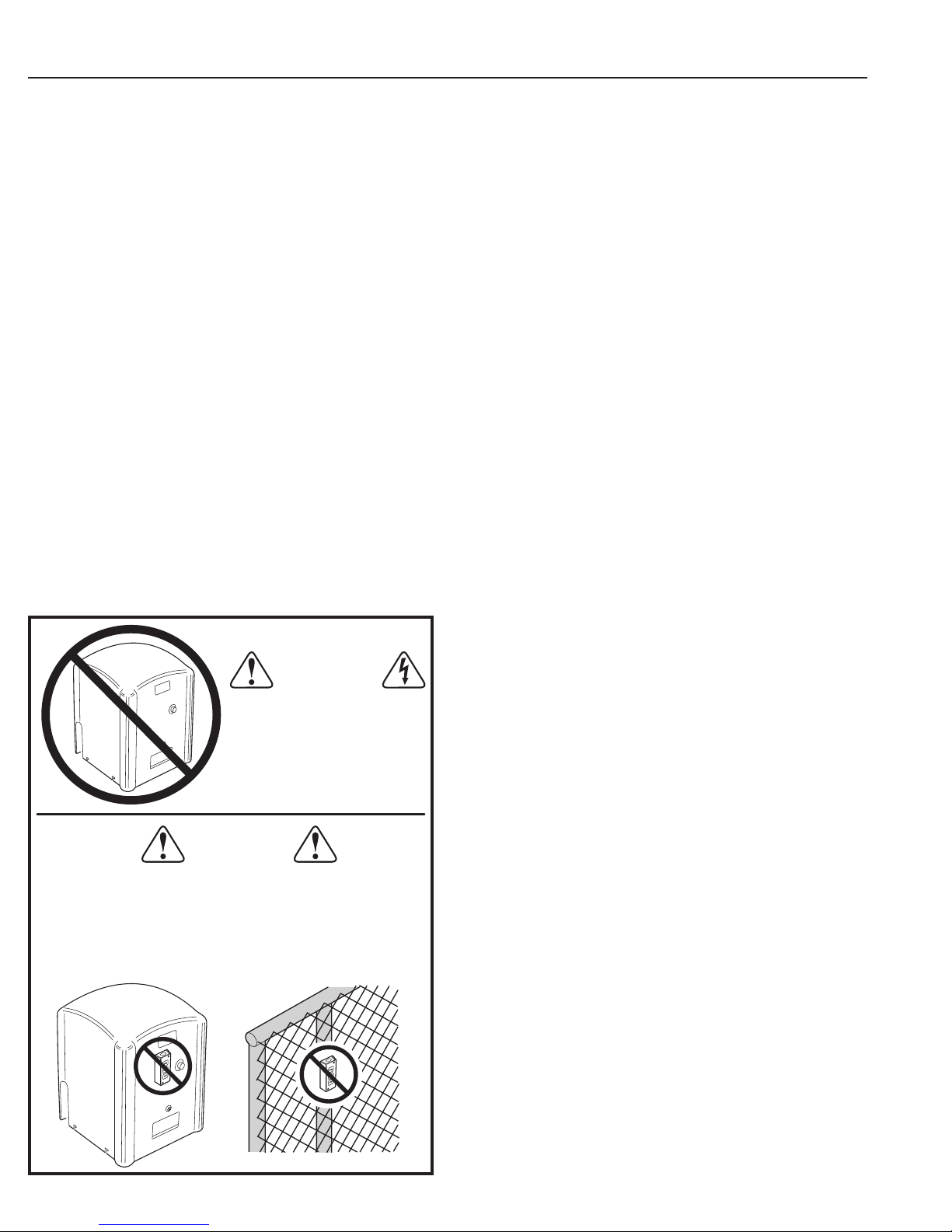

Safety Information.........................................31

Manual Disconnect ........................................32

Gate Obstruction Sensing Information ........................32

TYM 1000/2000 Exploded View and Parts List ..................33

Preventative Maintenance ..................................35

General ..............................................35

Lubrication............................................35

6-Month Preventative Maintenance.........................35

FCC Notice ...............................................35

Gate Operator Installation Checklist ..........................36

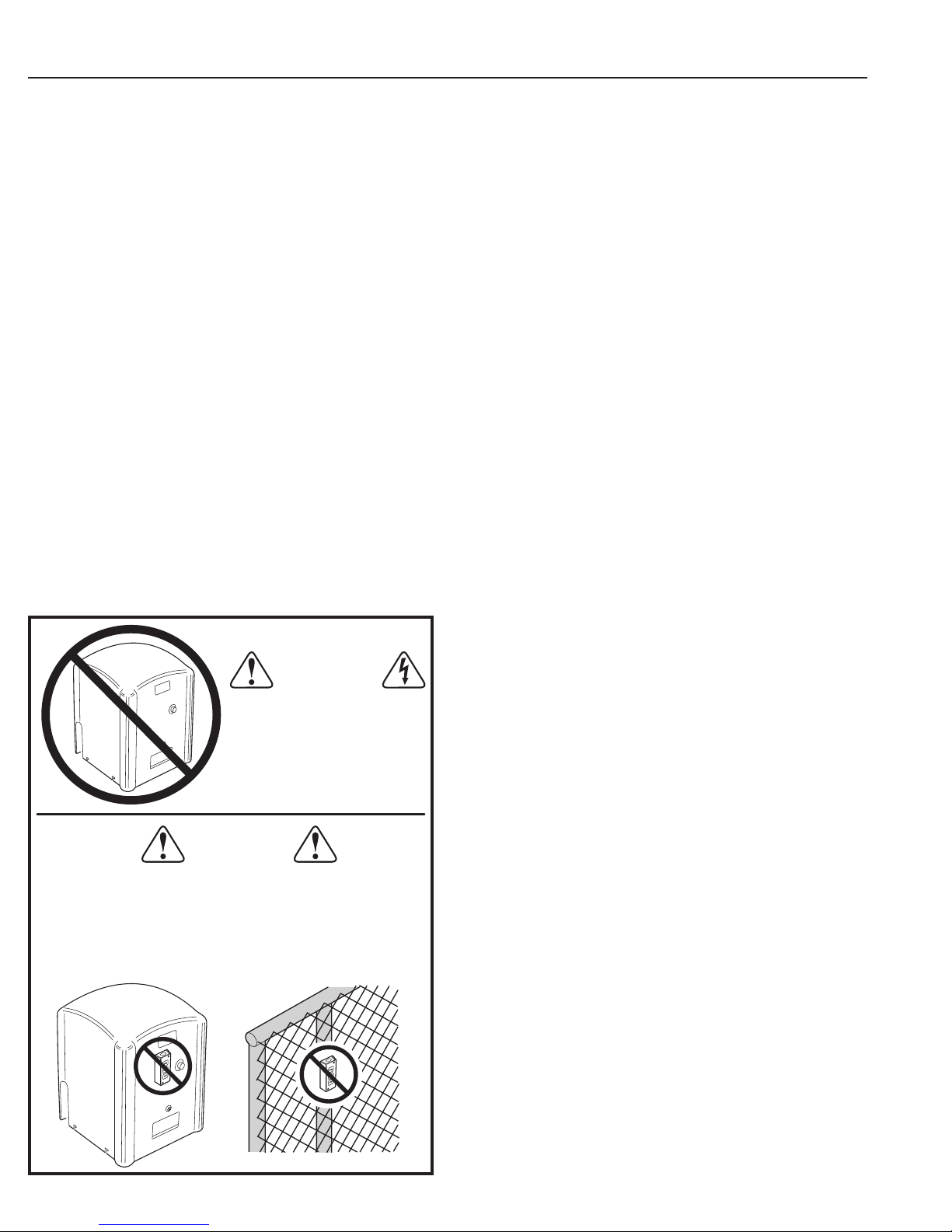

ONLY QUALIFIED TECHNICIANS

SHOULD WORK ON

LINEAR SLIDE GATE

OPERATORS

WARNING

WARNING

CONTROLS INTENDED FOR USER ACTIVATION MUST BE

LOCATED AT LEAST SIX FEET (6') AWAY FROM ANY MOVING

PART OF THE GATE AND WHERE THE USER IS PREVENTED

FROM REACHING OVER, UNDER, AROUND OR THROUGH THE

GATE TO OPERATE THE CONTROLS. OUTDOOR OR EASILY

ACCESSIBLE CONTROLS SHALL HAVE A SECURITY FEATURE

TO PREVENT UNAUTHORIZED USE.

TYMETAL