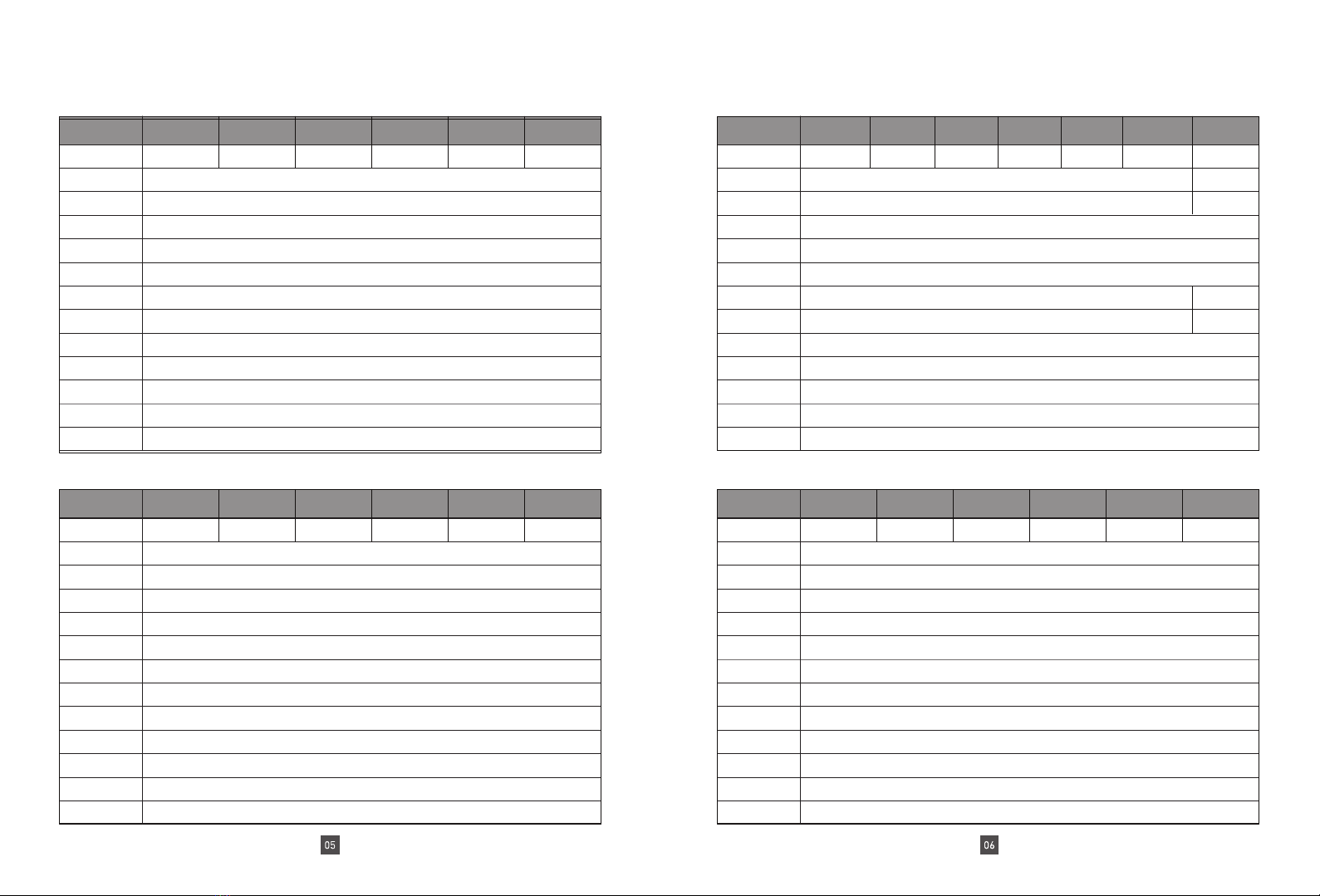

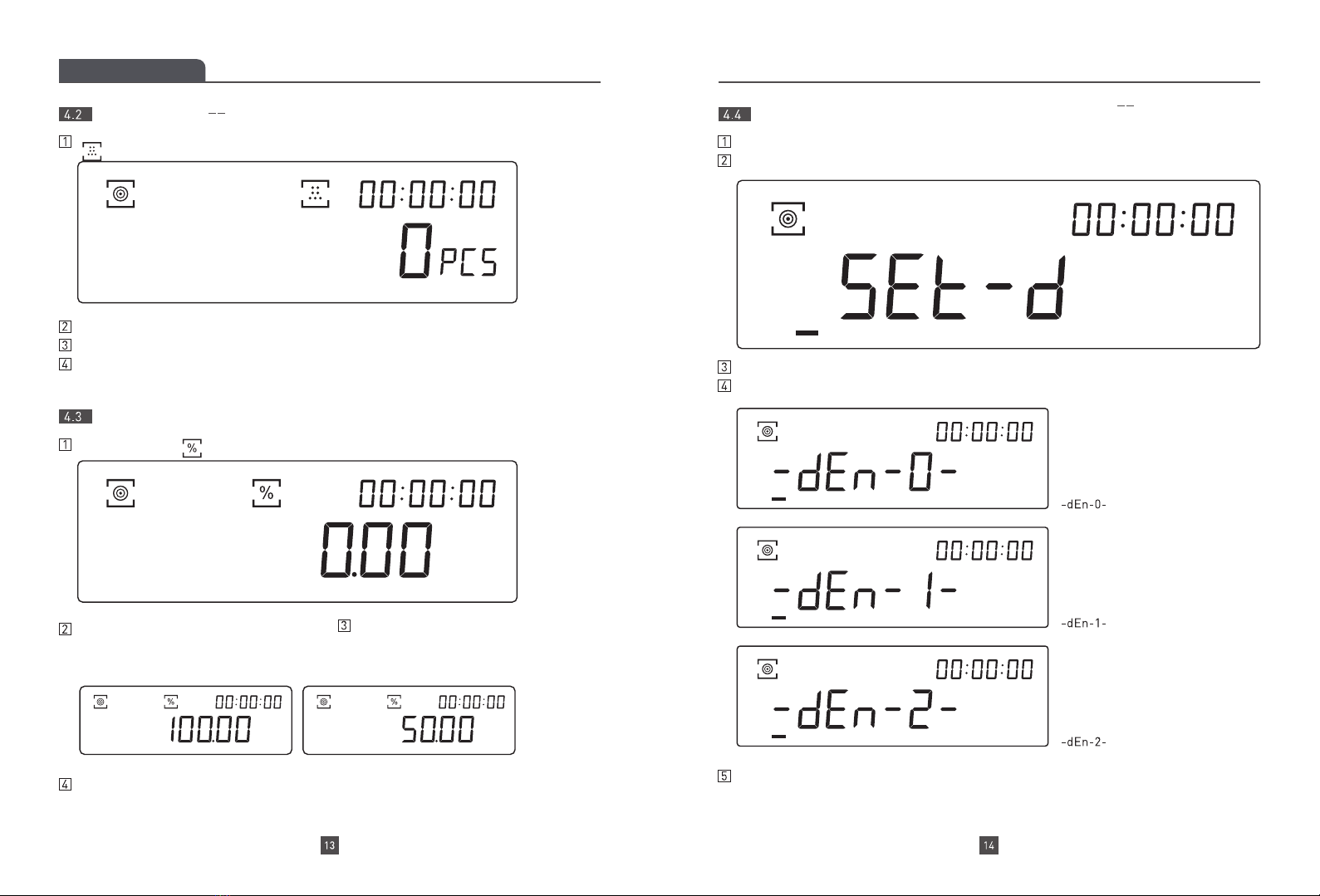

Put the balance on the stable desk, the desk can not be moved.

Adjust the 2 Leveling Feet on the bottom, until the bubble is

centered in the circle, then install the scale pan.

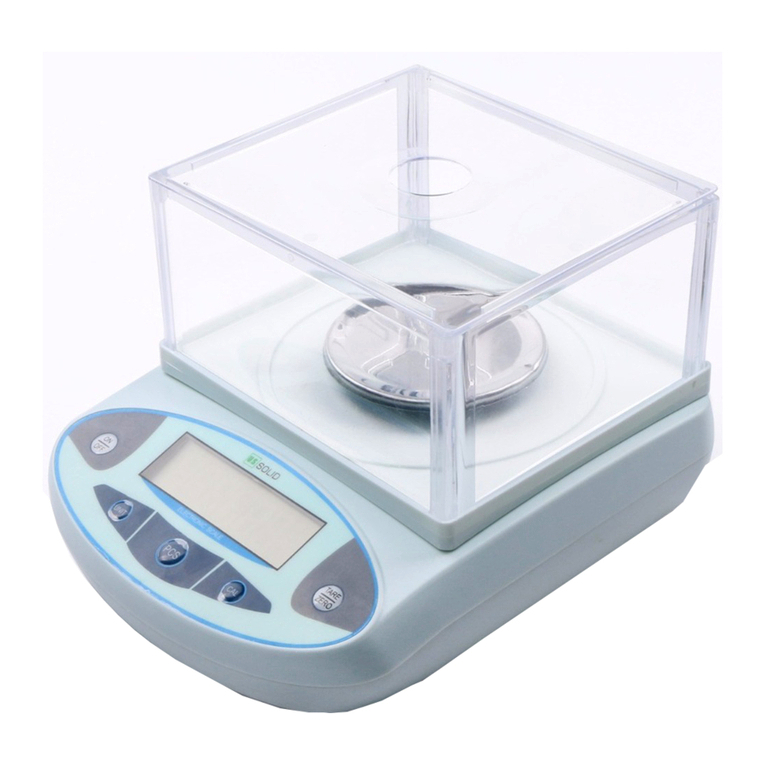

bubble right above

bubble right below

bubble left

bubble right

counterclockwise rotate two

leveling feet

clockwise rotate two

leveling feet

counterclockwise rotate left

leveling foot clockwise

rotate right leveling foot

counterclockwise rotate

right leveling foot

clockwise rotate left

leveling foot

Plug in the AC adapter

Press“ON”button and the display shows“0.0000”, the scale enters into the

weighing mode.

When the operating temperature changes, put the balance in the new place

for 2 hours under the “power on” state to adapt the balance to the new

temperature.

Attention: If the number on display is not stable at the first usage,

it is

caused by the temperature difference of the environment, you can

press ”TARE”button repeatedly

and let it stand for 30 minutes.

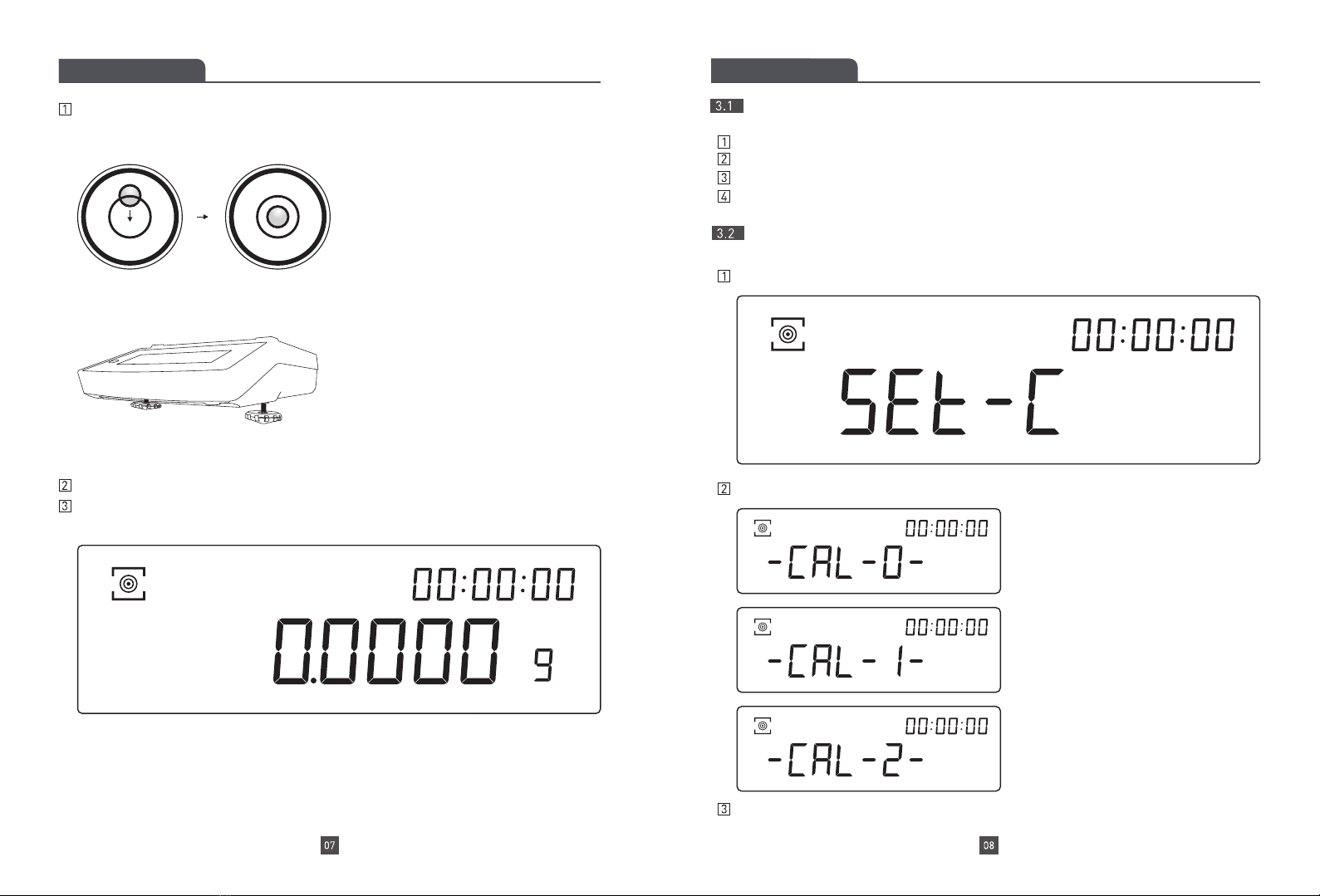

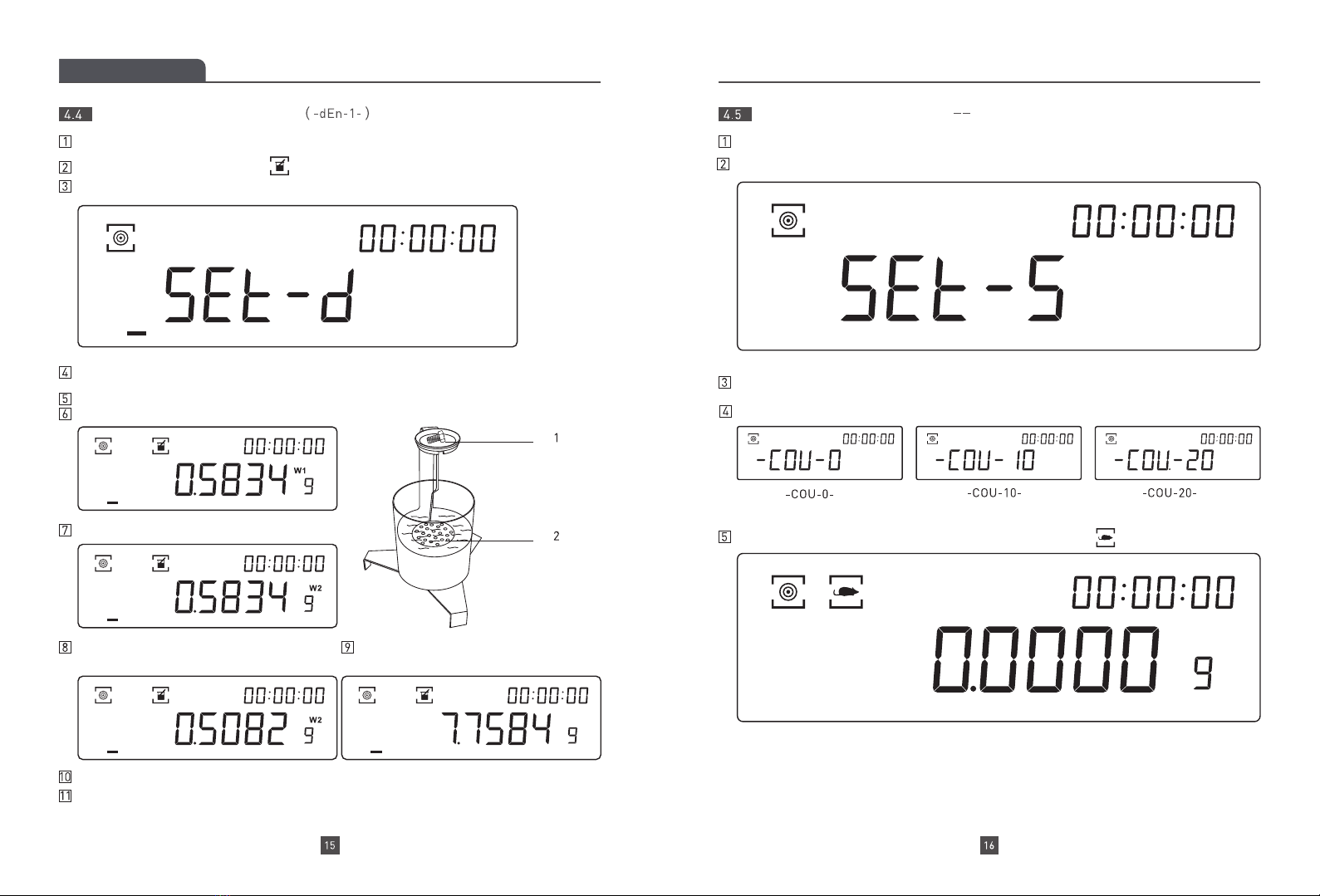

In order to get accurate weighing result, balance should be

calibrated

before the below usage scenarios.

Before first use

Balance power off for long time or power error.

After changing the operating environment.

Regularly in weighing procedure.

Choose the calibration (follow the

sequence) Press and hold“ON”

when display show “SET-C” release the button.

“CAL-0”external calibration(weight)

“CAL-1”internal calibration weight

(internal calibration balance)

“CAL-2”internal calibration weight

value adjustment(internal

calibration balance)

press “TARE”to save and exit the setup.

2. PREPARATION 3. CALIBRATION