Contents

DOCUMENT REVISION HISTORY.................................................................................................................................... 2

SIGNS AND ABBREVIATIONS ......................................................................................................................................... 4

SAFETY INSTRUCTIONS.................................................................................................................................................. 5

AVAILABLE MODIFICATIONS.......................................................................................................................................... 6

1. APPLICATION AND FUNCTIONALITY..................................................................................................................... 7

1.1. GENERAL INFORMATION................................................................................................................................... 7

1.2. SUPPORTED COMMUNICATION PROTOCOLS................................................................................................. 7

1.3. CONFIGURATION................................................................................................................................................. 7

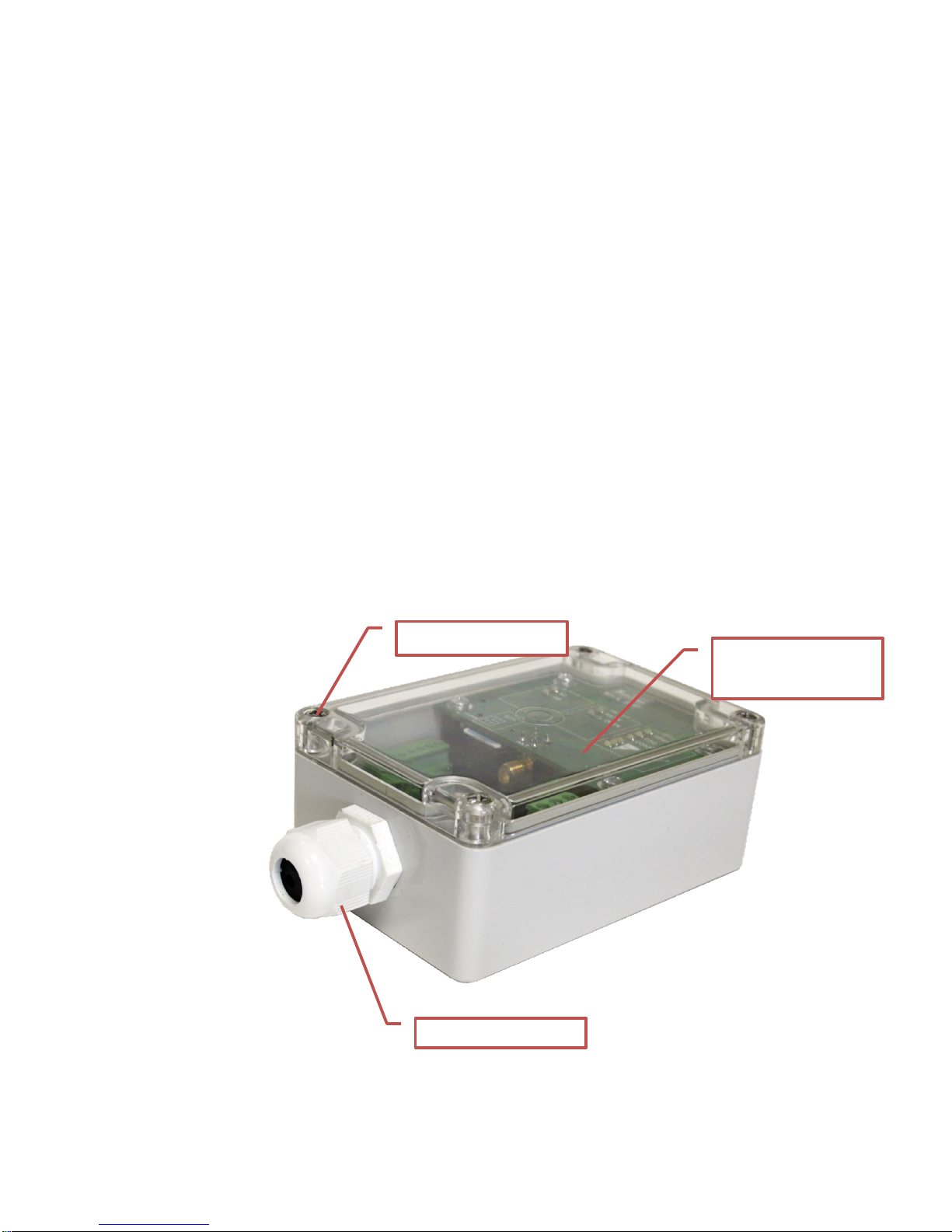

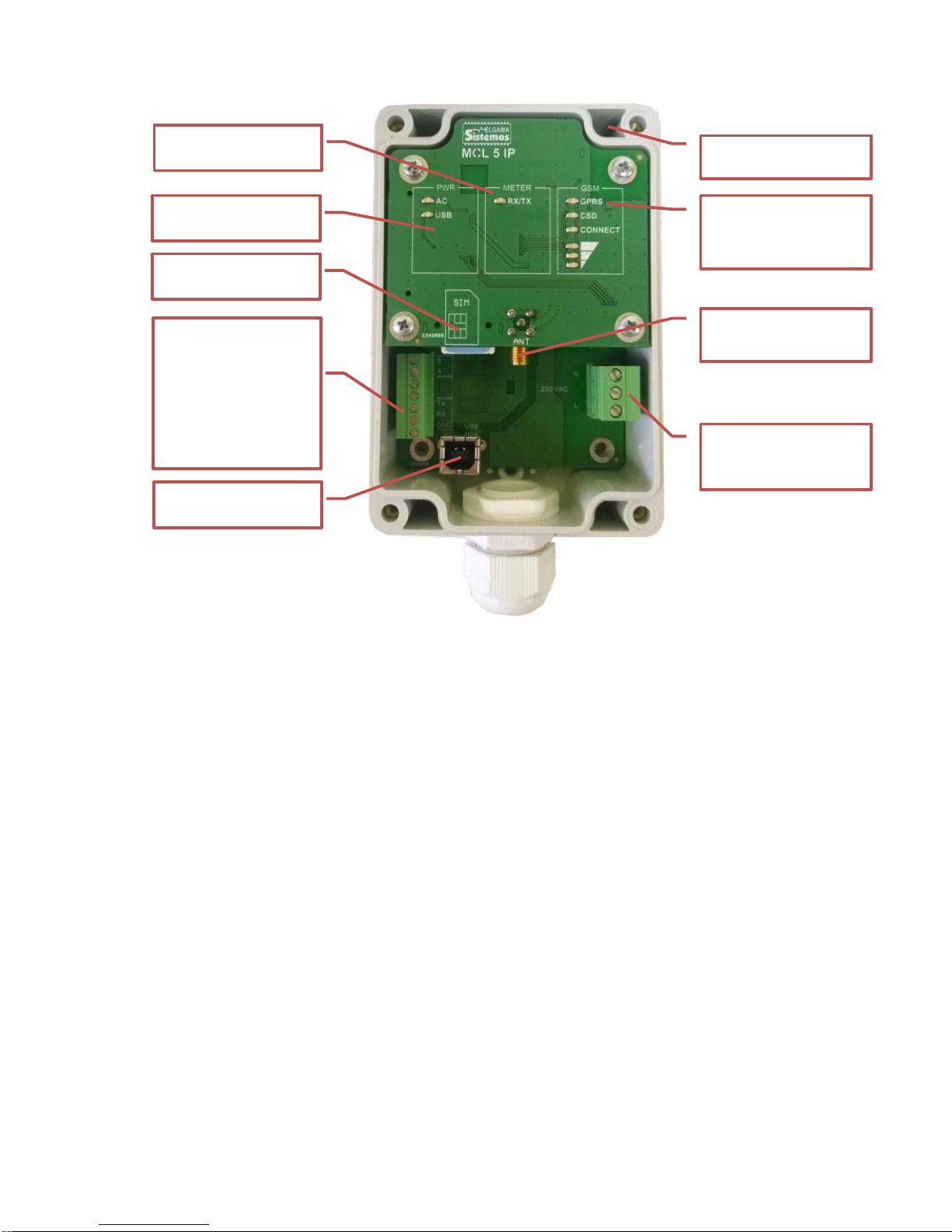

2. PRINCIPAL COMPONENTS OF THE CONTROLLER MCL 5 IP.............................................................................. 9

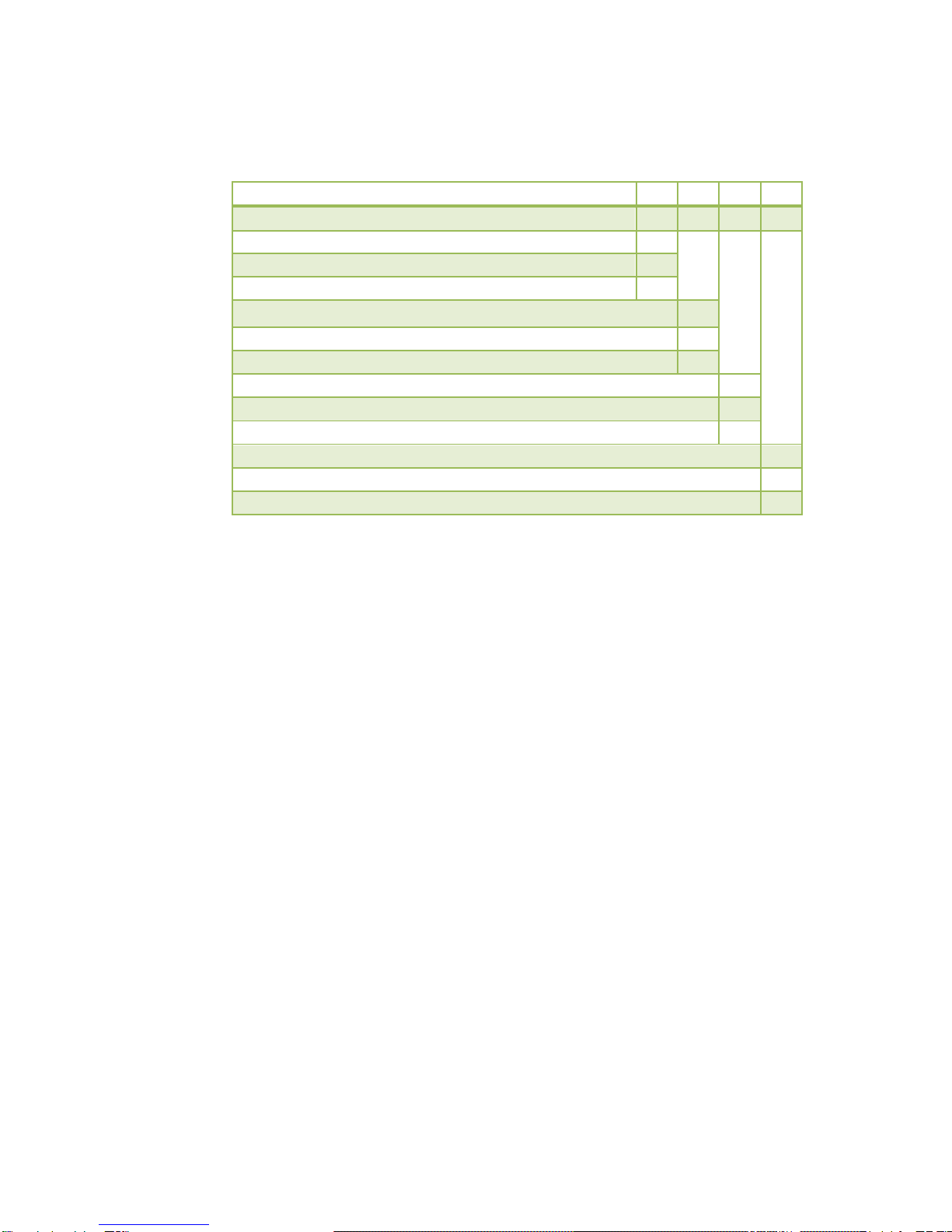

3. TECHNICAL CHARACTERISTICS.......................................................................................................................... 10

4. INSTALLATION........................................................................................................................................................ 12

4.1. INSTALLATION STEPS:..................................................................................................................................... 12

4.1.1 CONNECTING POWER CABLE TO THE MCL 5 IP............................................................................................... 13

4.2. SOCKETS AND INTERFACES........................................................................................................................... 13

4.3. CONNECTING METER/METERS OR OPTICAL READ-OUT HEAD OVER RS485 .......................................... 14

4.3.1. CONNECTING A METER OVER RS485 ........................................................................................................ 14

4.3.2. CONNECTING AN OPTICAL READ-OUT HEAD OVER RS485 ................................................................... 14

4.4. CONNECTING A METER OR OPTICAL READ-OUT HEAD OVER RS232....................................................... 15

4.4.1. CONNECTING A METER OVER RS232 ........................................................................................................ 15

4.4.2. CONNECTING AN OPTICAL READ-OUT HEAD OVER RS232 ................................................................... 15

4.5. CONNECTING A PC OVER USB PORT FOR PARAMETERIZATION.............................................................. 15

5. LABELLING INFORMATION................................................................................................................................... 16

6. PARAMETERIZATION GUIDE................................................................................................................................. 16

6.1. INITIAL INFORMATION...................................................................................................................................... 16

6.2. PROCEDURE OF LOCAL PARAMETERIZATION............................................................................................. 17

7. PARAMETERIZATION............................................................................................................................................. 21

7.1. SECURITY........................................................................................................................................................... 21

7.2. DEFAULT PASSWORD...................................................................................................................................... 21

7.3. APN..................................................................................................................................................................... 21

7.4. AUTOMATIC REBOOT....................................................................................................................................... 21

7.5. FIRMWARE UPDATE ......................................................................................................................................... 21

7.5.1. AUTOMATIC FIRMWARE UPDATE............................................................................................................... 21

7.5.2. MANUAL FIRMWARE UPDATE .................................................................................................................... 21

7.6. BYTE W. TIMEOUT IN X BYTES........................................................................................................................ 21

8. EVENT LOG............................................................................................................................................................. 21

8.1. EVENT LOG RECORD FORMAT ....................................................................................................................... 21

8.2. LOGGING EVENTS............................................................................................................................................. 21

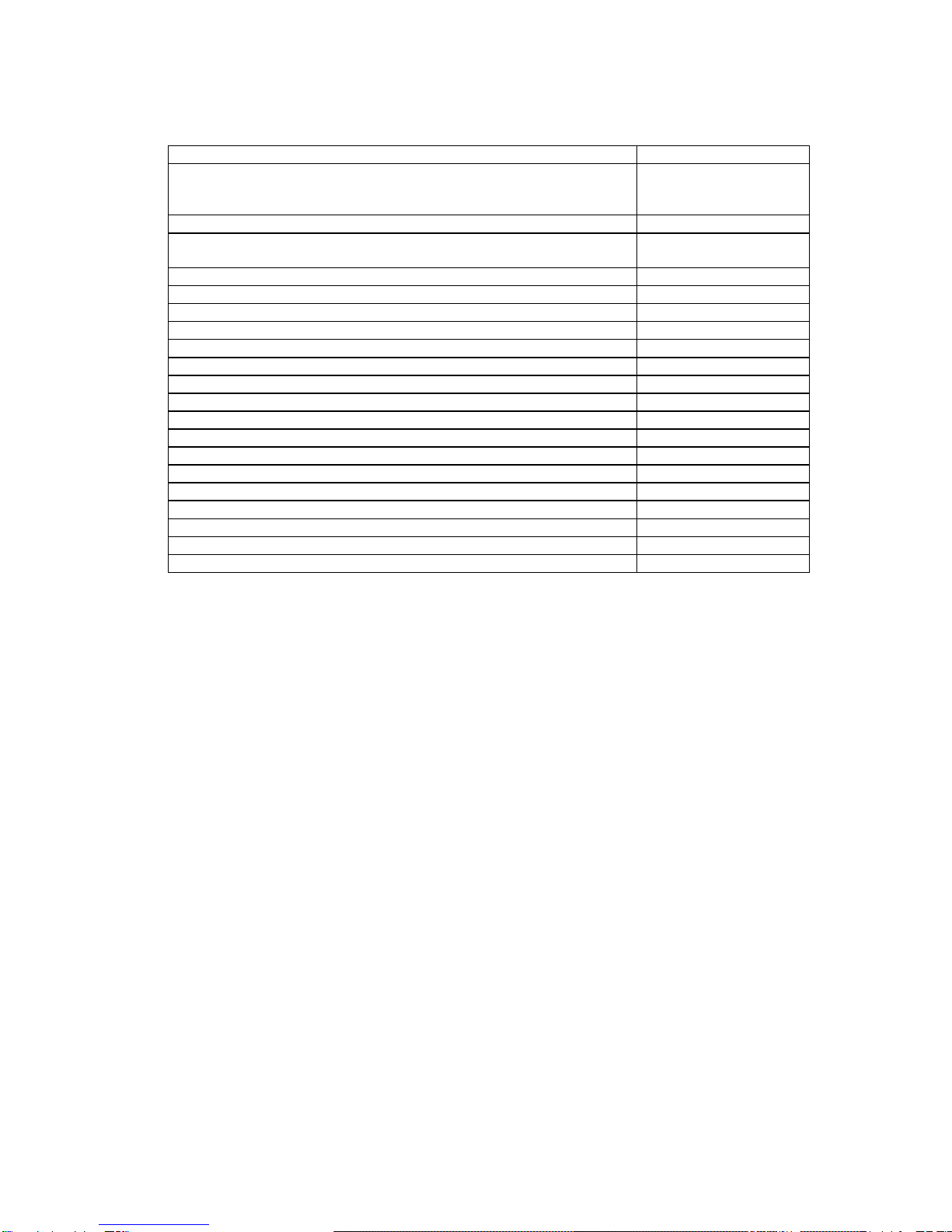

ANNEX A. CONTROLLER MENU AND CONFIGURATION SETTINGS......................................................................... 23

ANNEX B. USB INSTALLATION GUIDE......................................................................................................................... 27

ANNEX C. MANUFACTURER’S GUARANTEE .............................................................................................................. 32