7

MANUAL - SOLVENT RECYCLER - URS900SSW Revised 2011-07

2) Fill the Distillation Tank

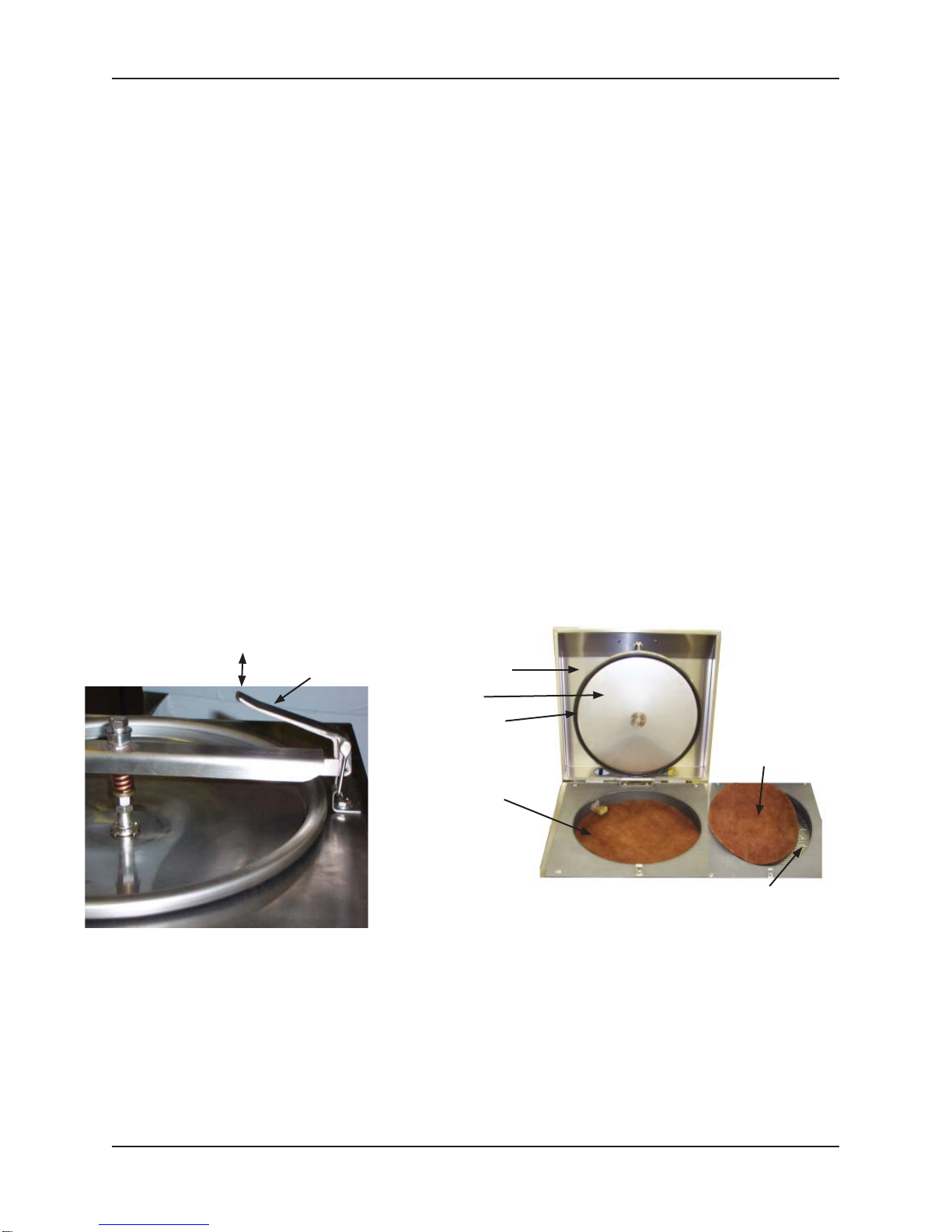

a) First remove the Tank Filter Pad and the Tank Screen.

b) Pour the dirty water mixture into the Distillation Tank up to 4 INCHES BELOW THE RETAINER

RING. When pouring the water, make sure all of it goes into the Liner Bag, not between the Liner Bag

and the wall of the Distillation Tank. Also, to avoid damaging the rim of the Tank, do not rest the water

container on the Tank rim. After filling, clean the Lid Gasket and the top of distillation tank.

c) Replace the Filter Pad and Screen.

d) Close the Tank Lid, lock down the Lid Clamp and close the Safety Cover.

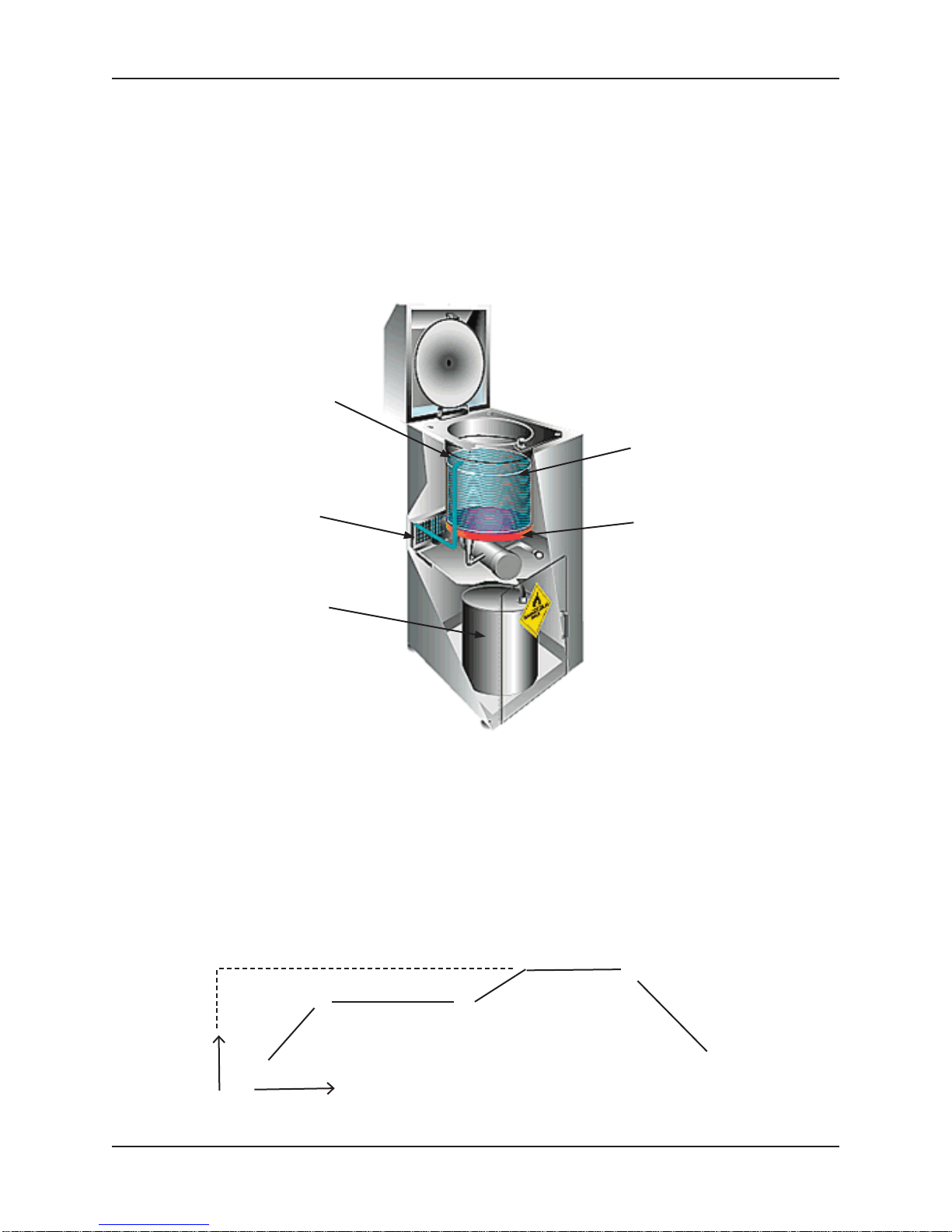

3) Position waste liquid Receiving Pail

Open the Door and position a pail (not provided) with a minimum size of 5 US Gal (20 L) inside the cabi-

net. Insert the Liquid Outlet Tube (short and curved) into the top opening of the pail. The Outlet Tube must

extend below the rim of the pail to prevent spillage.

4) Change temperature SET POINT if necessary using SETUP MODE. The boiling point of pure water

is 100°C (212°F). The BP of the dirty mixture will be considerably higher than this. The SET POINT is

set at the factory to 150°C (572°F). If the dirty water mixture is unsually contaminated, the SET POINT

may have to be increased. The maximum is 200°C (392°F). If the dirty mixture does not boil at the

highest SET POINT of 200°C, this unit will not be able to recycle the mixture. To allow recycling

at 200°C or less, reduce the boiling point of the dirty mixture by recycling more often (ie:before the

level of contaminaton becomes too high).

5) Press START to begin distillation.

To change settings, enter Setup Mode.

SETUP MODE

To change settings, enter Setup Mode: while pressing SETUP, press START. “SET-UP MODE” is dis-

played. To change the temperature units from °C to °F, press and hold the + and - keys together

for 2 seconds.

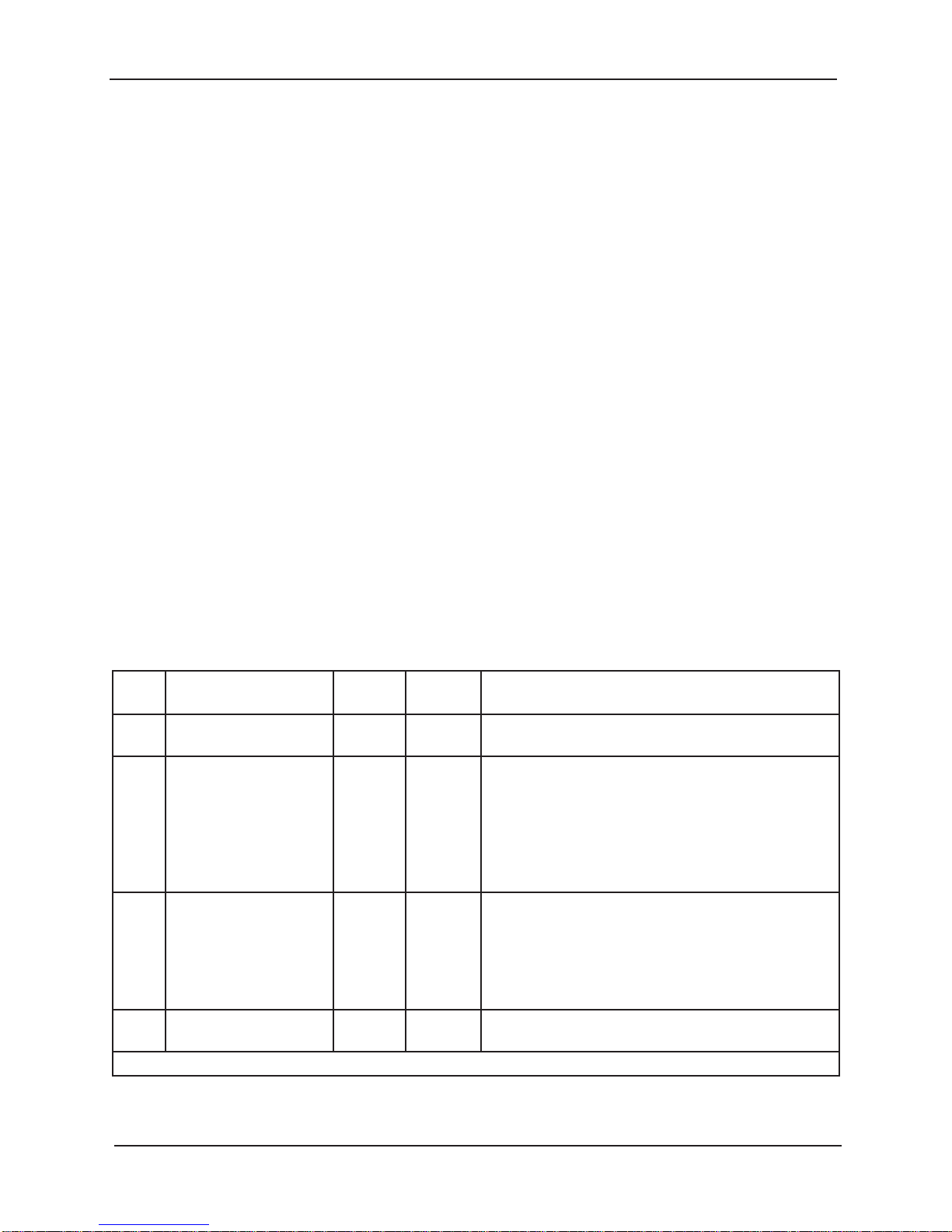

STEP SETTING ADJUST ACCEPT DESCRIPTION

1SET-PT = XXX°C (°F) + OR - OK Leave the SET POINT at the factory setting un-

less the dirty mixture does not boil.

2 POWER = XXX% + OR - OK

If boiling is too vigorous due to one or more of the

following conditions, decrease POWER by one

increment or more.

• vapour leaks at the Lid Gasket

• recycled water comes out too hot

• waste material is carried into the recycled water

Otherwise, use 100%.

3 SHUT-OFF = AUTO** + OR - OK

If too much water remains in the Distillation Tank

after recycling and the problems in the Trou-

blshooting Guide have been ruled out, over-ride

the AUTO SHUT-OFF and manually select a heat-

ing time (eg: 4 hours). The heater will stay on for

this amount of time and then cooling will begin.

4 BAKE TIME = XXM + OR - OK Only available when SHUT-OFF =AUTO. In-

crease if residue (puck) is too wet.

*** WARNING: SHUT-OFF TIME MUST NOT BE SET TO MORE THAN 8 HOURS MAXIMUM ***