UnionSpecial 39500PA Setup guide

Other UnionSpecial Sewing Machine manuals

UnionSpecial

UnionSpecial 80800R Setup guide

UnionSpecial

UnionSpecial 81200 SERIES User manual

UnionSpecial

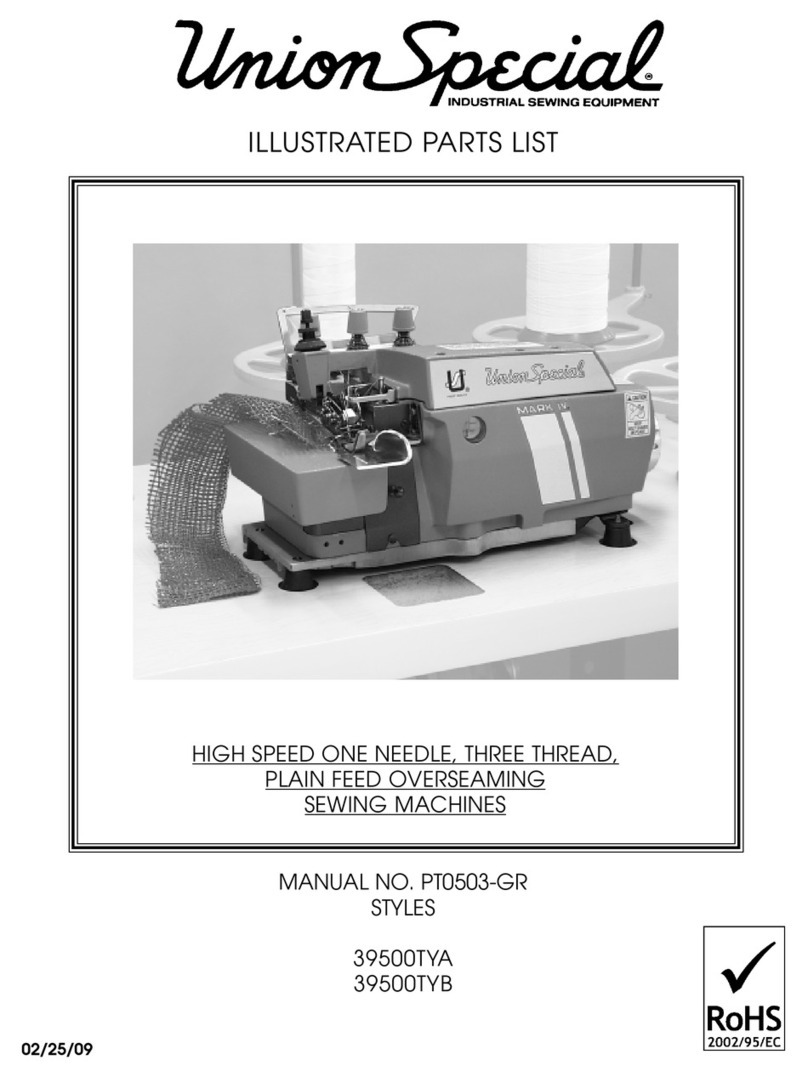

UnionSpecial 39500TYA Setup guide

UnionSpecial

UnionSpecial 51300 Series Instruction sheet

UnionSpecial

UnionSpecial SP100 Series User manual

UnionSpecial

UnionSpecial Columbia 100X Parts list manual

UnionSpecial

UnionSpecial BML211C2 User manual

UnionSpecial

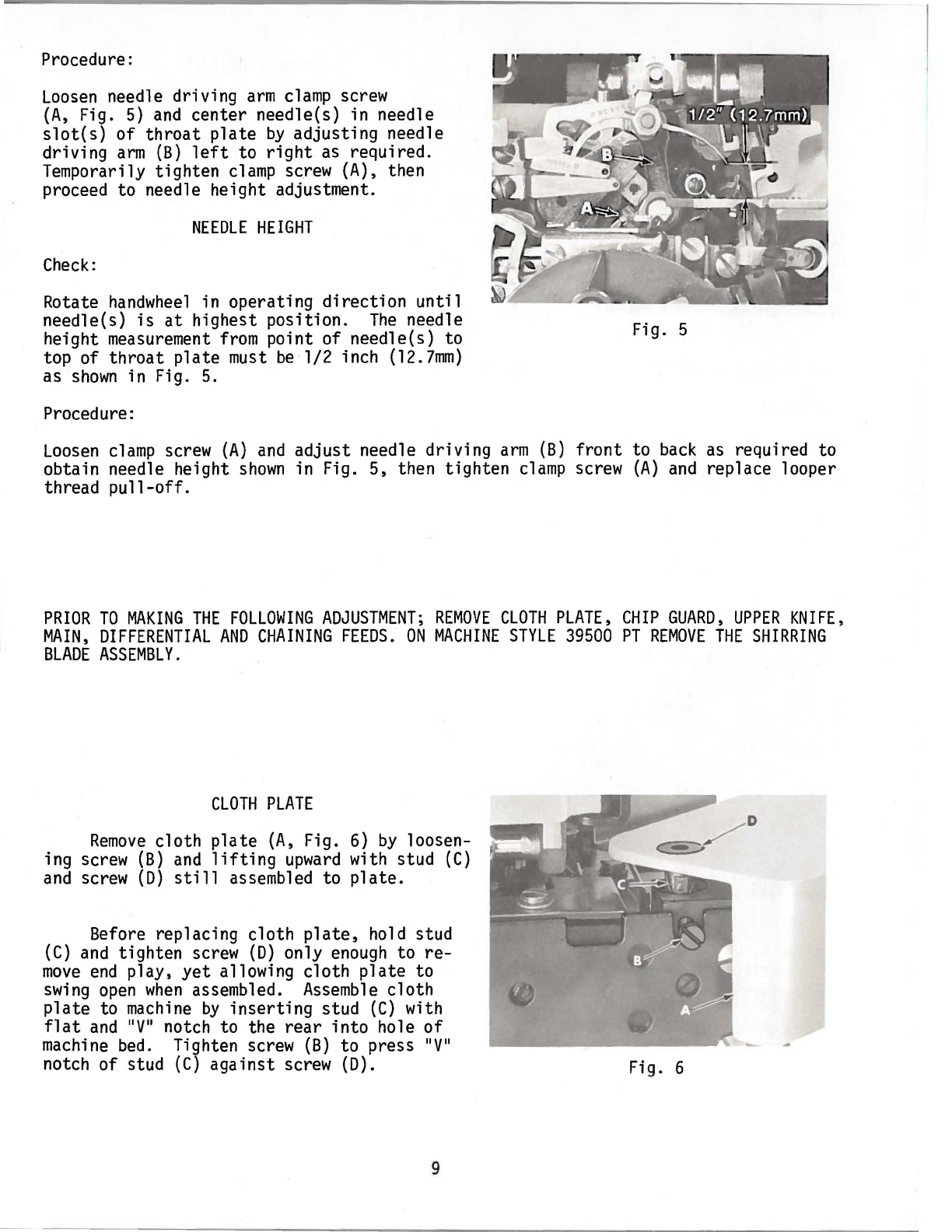

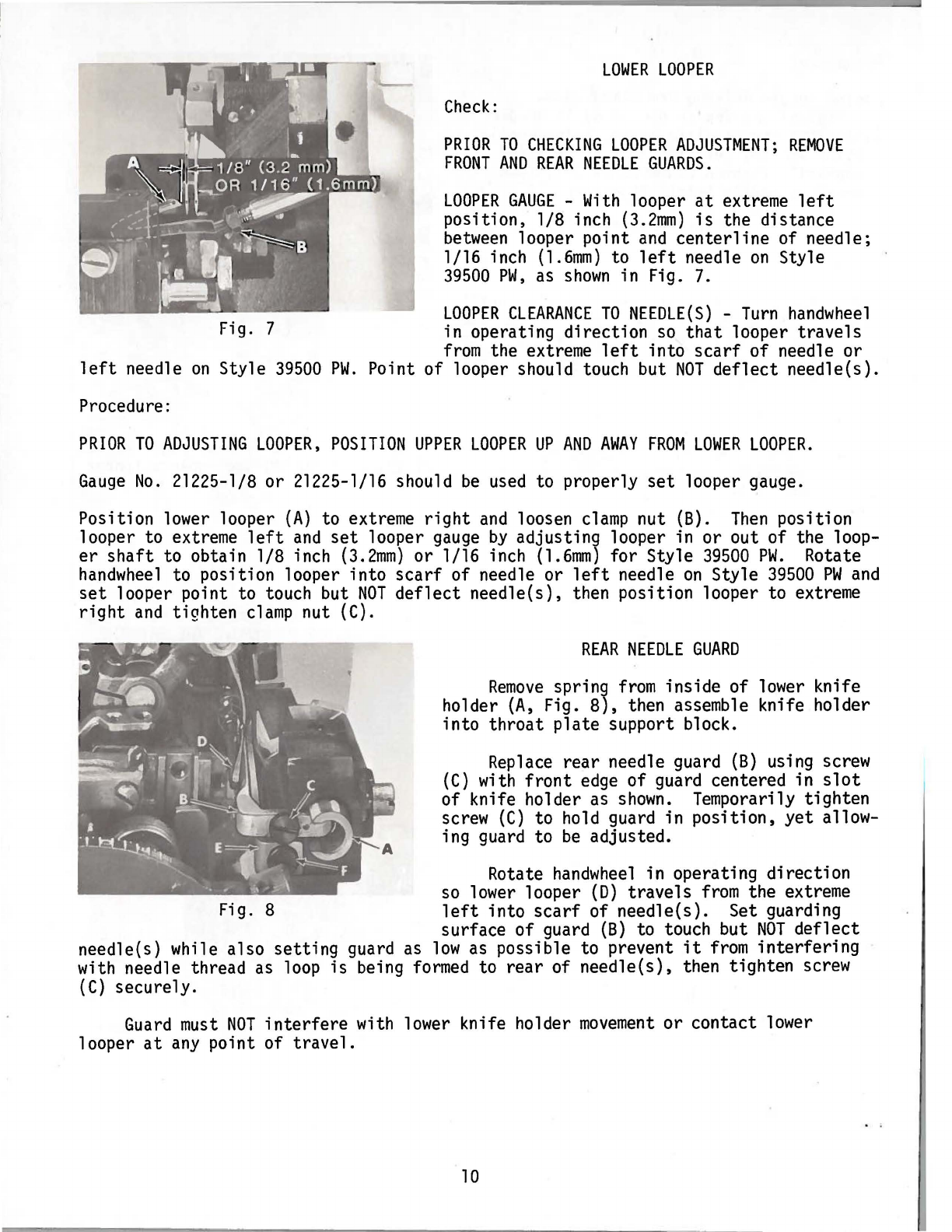

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial BML213CD User manual

UnionSpecial

UnionSpecial BCE300 User manual

UnionSpecial

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial 2200A User manual

UnionSpecial

UnionSpecial 50000 Series Setup guide

UnionSpecial

UnionSpecial CLASS 2200 User manual

UnionSpecial

UnionSpecial P300-0 Series User manual

UnionSpecial

UnionSpecial BC200 User manual

UnionSpecial

UnionSpecial PL 1096 User manual

UnionSpecial

UnionSpecial 63400 Series Instruction sheet

UnionSpecial

UnionSpecial 81300A Setup guide

UnionSpecial

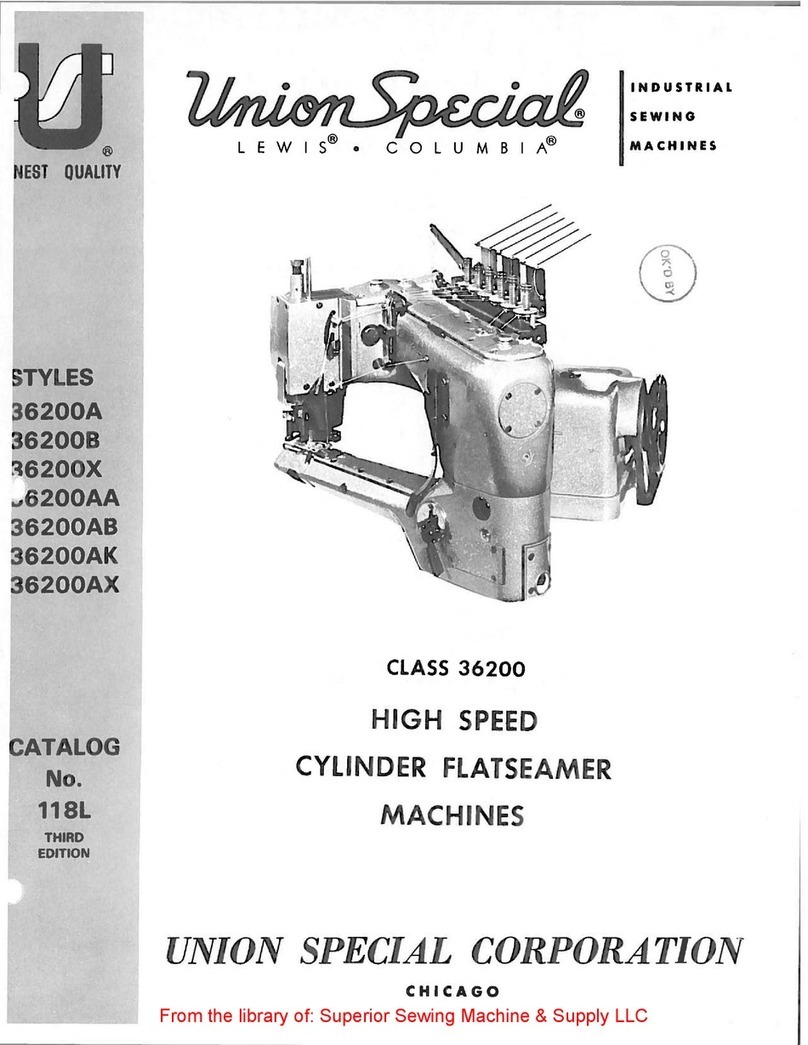

UnionSpecial 36200 Series Instruction sheet