Please read the IFU carefull before fitting. Onl correct usage will

warrant the function.

1. Intended Use

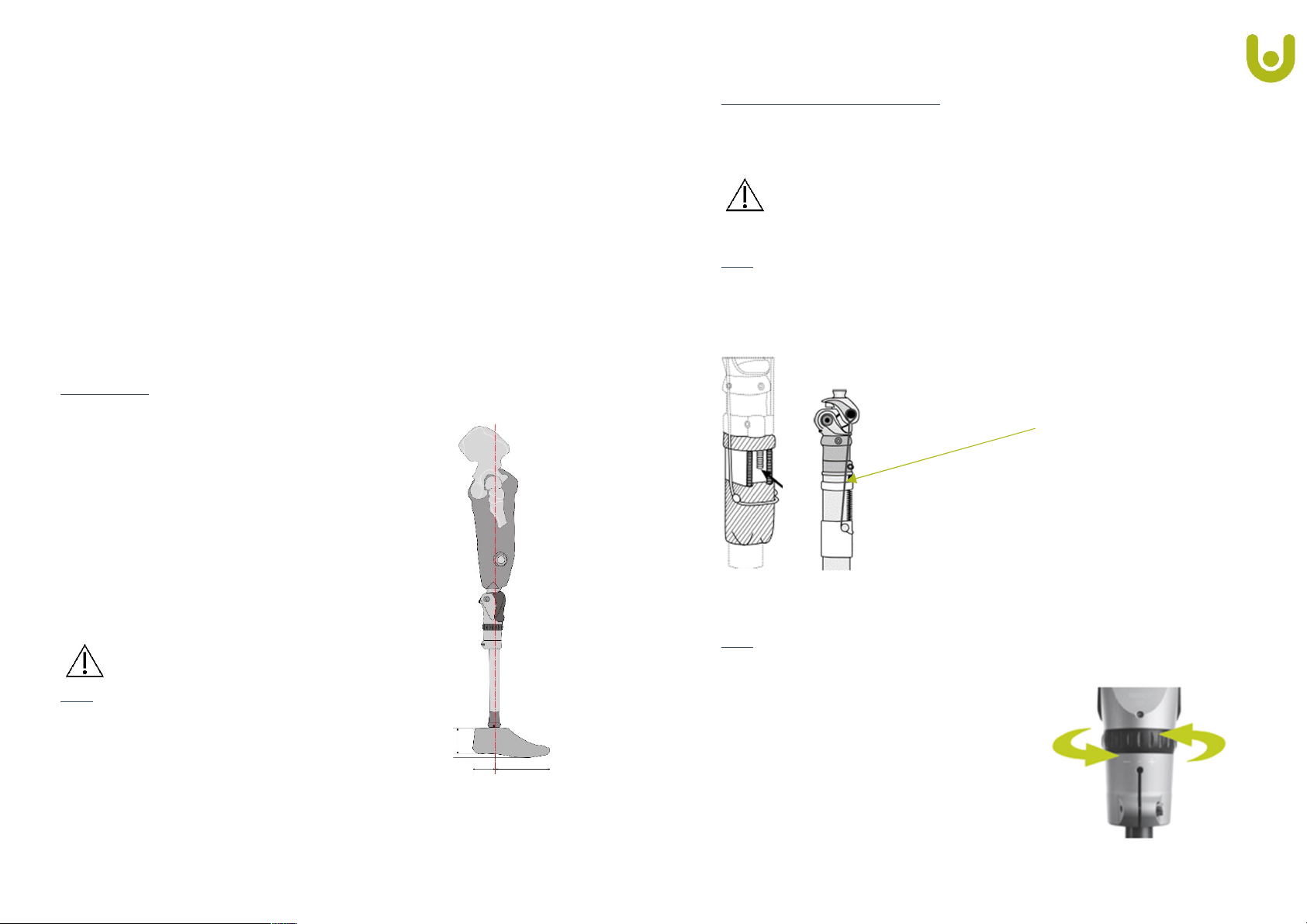

The knee joints are the connection between a prosthetic socket and a modular

prosthetic limb prosthesis with monocentric knee function.

2. Technical Data

•Load dependent brake for stance phase protection

•Spring extender to support the extension

•Rear shifted axis

•Connection proximal: pyramid

•Connection distal: JT05 pyramid

JT09 34 mm tube connection

•Max. weight: JT05 100 kg

JT09 150 kg

•Mobility level: 1 und 2

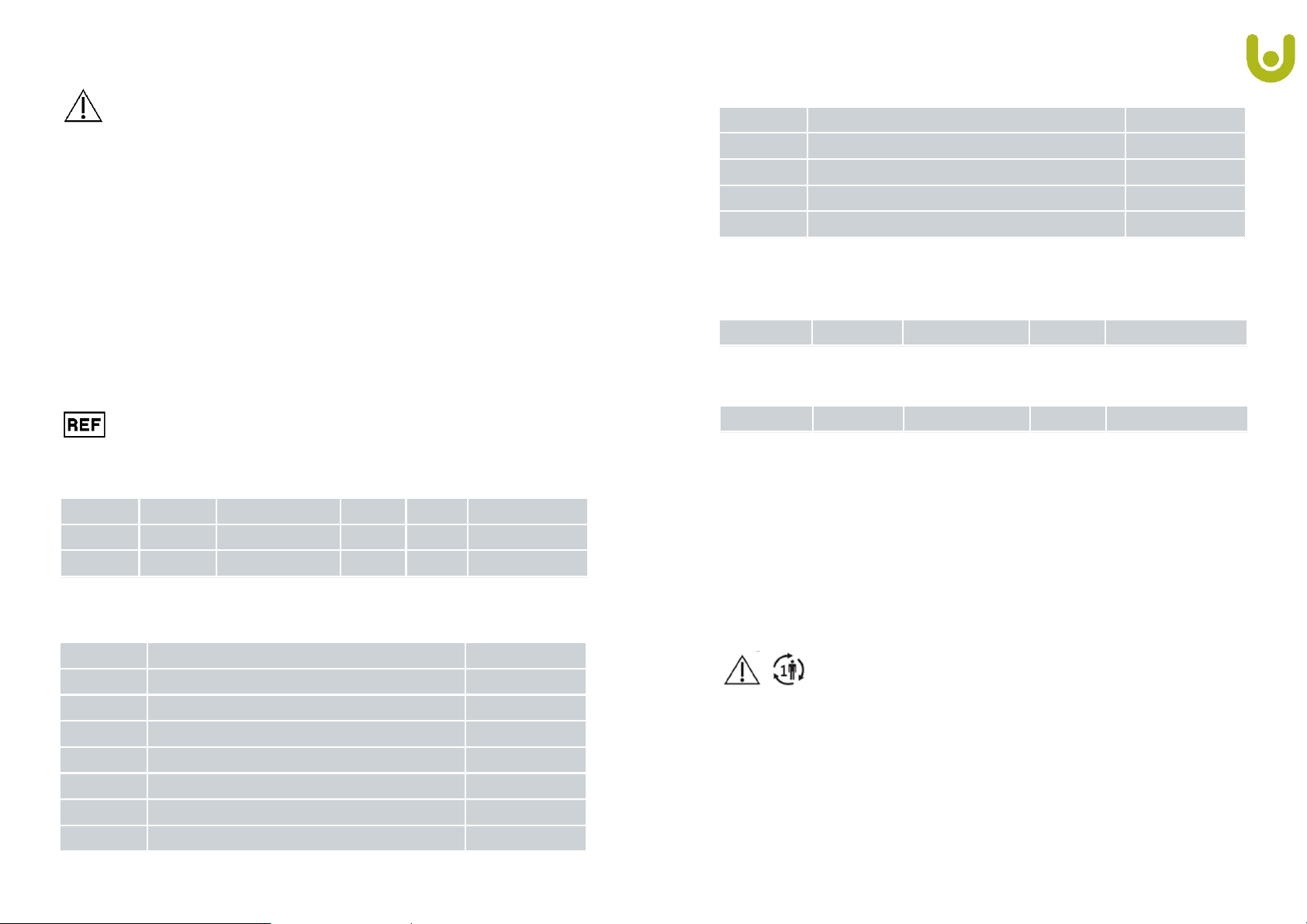

2.1 Service parts for JT05

2 3

Order-No. Material Installation height

(above the axis

center of rotation)

Weight Flexion

angle

Article number

JT05 St Steel 27 mm / 56 mm 530 g 170 ° 4 130 010 00 22 000

JT05 Ti Titanium 27 mm / 56 mm 355 g 170 ° 4 130 010 00 33 000

JT09 Aluminum 26 mm / 117 mm 890 g 145 ° 4 176 010 01 00 000

Order-No. Description Article number

E JT05 01 Brake Bushing for K5 4 130 009 01 00 000

E JT05 02 Bushing Safety Device for K5 4 130 009 02 00 000

E JT05 03 Axis Screw for K5 4 130 009 03 00 000

E JT05 04 Extension Stop, distal for K5 4 130 009 04 00 000

E JT05 05 Rubber bumper 4 130 009 05 00 000

E JT05 06 Brass washer, small, 2 pieces 4 130 009 06 00 000

E JT05 07 Swing axis holding device 4 130 009 07 00 000

E JT05 08 Swing axis 4 130 009 08 00 000

- English -

2.2 Recommended attachment for JT09

A4 Ti400 Tube adapter 34 mm, length 400 mm

A30 34 mm Clampfit to 30 mm tube

3. Indication/ Contraindication

Indicationen:

•Transfemoral amputation

Contraindicationen:

•not known

4. Side effects

There are no known side effects.

5. General safet instructions

•This medical device is designed for single patient, multiple use.

•Fitting/service of this medical device is only allowed by a certificated orthopedic

professional.

•The professional should instruct the correct use of the device to the user.

•The joint must be protected against dust, moisture, aggressive media, and

mechanical forces so its function is not affected.

•The joint is intended for use at temperatures from 10°C to 50°C.

Order-No. Description Article number

E JT05 09 Brass washer, large, 2 pieces 4 130 009 09 00 000

E JT05 10 Extension stop, superior 4 130 009 10 00 000

E JT05 11 Extension assist for JT05 complete 4 130 010 00 00 001

E JT05 16 Extension assist cable, lenght 304 mm 4 130 019 05 00 000

E JT05 17 Centering ring 4 130 009 12 00 001

Order-No. Material Weight limit Weight Article number

A4 Ti400 Titanium < 150 kg 435 g 4 113 050 34 33 400

Order-No. Material Weight limit Weight Article number

A30 Aluminum < 100 kg 91 g 4 610 070 00 00 008

- English -