GENERAL

MISUSE OF THIS PRODUCT MAY CAUSE EXPLOSION AND PERSONAL INJURY.

THESE INSTRUCTIONS MUST BE THOROUGHLY READ AND UNDERSTOOD

BEFORE UNIT IS INSTALLED.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISIONS 1 & 2,

GROUPS A, B, C AND D; CLASS II, DIVISIONS 1 & 2, GROUPS E, F AND G;

CLASS III; OR NON-HAZARDOUS LOCATIONS ONLY. -50 °C (-58 °F) ≤ Tamb.

≤ 95 °C (203 °F), ENCLOSURE TYPE 4X.

THIS EQUIPMENT IS ATEX CERTIFIED (OPTION M419) FOR EQUIPMENT CAT-

EGORY 2. SUITABLE FOR APPROPRIATE USE IN GAS ZONE 1 AND DUST ZONE

21 APPLICATIONS.

0539 DEMKO 03 ATEX 0252466X

II 2 G EEx d IIC T6

II 2 D T+85 °C

-50 °C ≤ Tamb. ≤+80 ºC, IP66

BEFORE INSTALLING, CHECK THE SENSOR MODEL SELECTED FOR

COMPATIBILITY TO THE PROCESS MEDIA IN CONTACT WITH THE SENSOR AND

WETTED PARTS.

PROOF PRESSURE* LIMITS STATED IN THE LITERATURE AND ON NAME-

PLATES MUST NEVER BE EXCEEDED, EVEN BY SURGES IN THE SYSTEM.

OCCASIONAL OPERATION OF UNIT UP TO PROOF PRESSURE IS ACCEPTABLE

(E.G., START-UP, TESTING). CONTINUOUS OPERATION SHOULD NOT EXCEED

THE DESIGNATED OVER RANGE PRESSURE.

*Proof Pressure

The maximum pressure to which a pressure sensor may be occasionally subjected,

which causes no permanent damage (e.g., start-up testing). (May require set-point

adjustment).

THESE PRODUCTS DO NOT HAVE ANY FIELD REPLACEABLE PARTS. ANY

SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 1.

The Spectra-12 switch utilizes a diaphragm or a piston sensor to detect a pressure

change. The response, at a predetermined set point, actuates or deactuates a SPDT

or DPDT snap-acting switch, converting a pressure signal into an electrical signal.

Control set point may be varied by turning the internal slotted adjustment screw

according to procedures outlined in Part II-Adjustments.

Tools Needed

1-1/6" Open end wrench

MOUNTING

ALWAYS LOCATE UNITS WHERE SHOCK, VIBRATION AND AMBIENT TEMPERATURE

FLUCTUATIONS ARE MINIMAL. DO NOT MOUNT IN AMBIENT TEMPERATURE

AREAS EXCEEDING 203°F (IF UL/cUL APPROVAL IS APPLICABLE) OR 80 °F (IF

ATEX APPROVAL IS APPLICABLE). IF SEVERE PRESSURE SURGES ARE EXPECTED,

CONSIDER THE USE OF A PRESSURE SNUBBER.

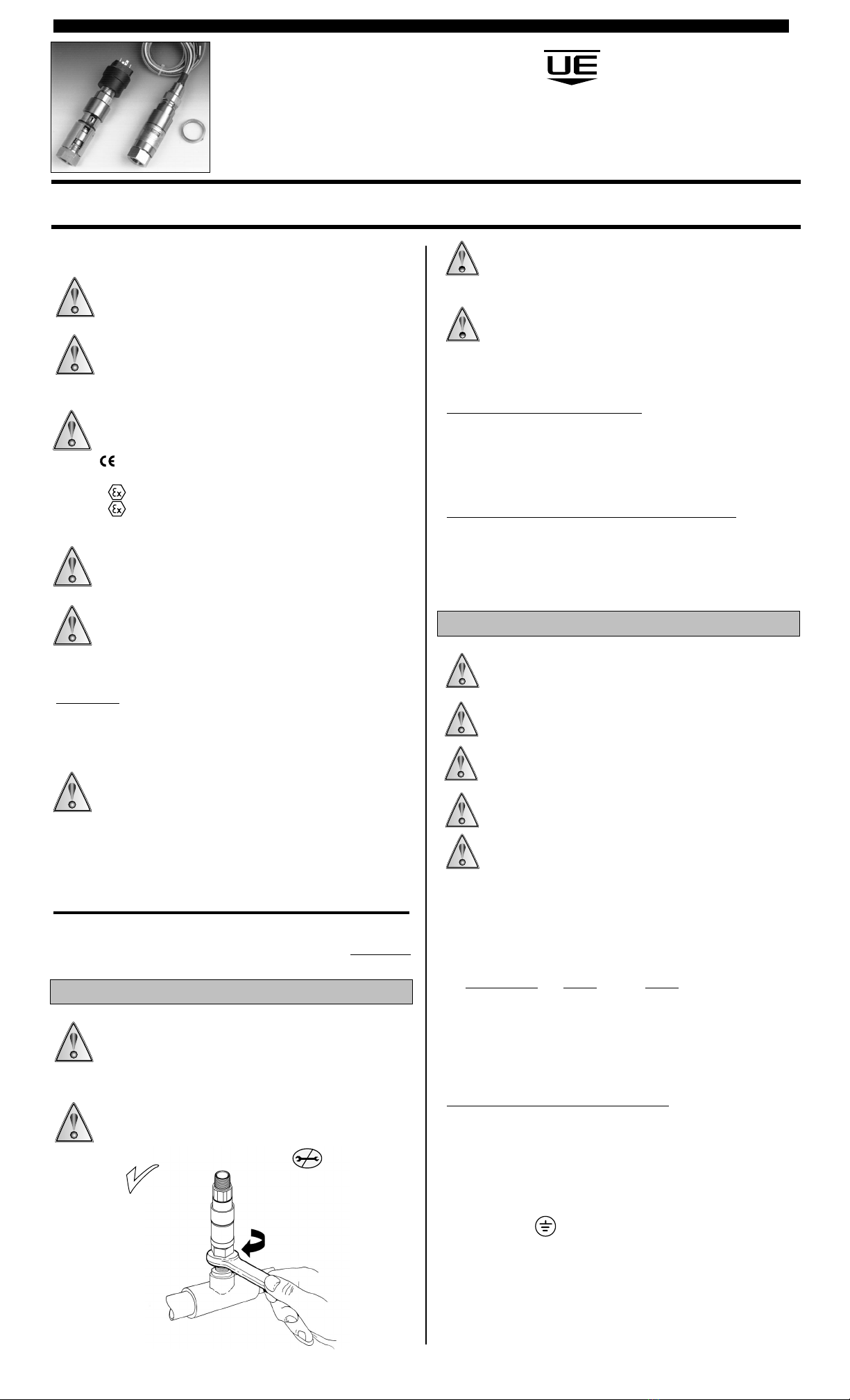

FOR PRESSURE MODELS, MOUNT USING PRESSURE CONNECTION: ALWAYS USE A

WRENCH ON PRESSURE CONNECTION WRENCH FLAT. (SEE FIGURE 1)

FOR DIFFERENTIAL PRESSURE MODELS, MOUNT UNIT AGAINST A RIGID

SUPPORT USING THE MOUNTING BRACKET ATTACHED TO THE SENSOR

ASSEMBLY. THEN CONNECT THE HIGH AND LOW PRESSURE CONNECTIONS

(HIGH PRESSURE PORT IS ON THE LEFT, WHEN FACING THE UNIT).

UNIT MAY BE MOUNTED IN ANY POSITION. HOWEVER, IF INSTAL-

LATION LOCATION RESULTS IN FREQUENT EXPOSURE TO

LIQUID IT IS RECOMMENDED THAT THE UNIT BE MOUNTED VERTICALLY WITH

THE PRESSURE CONNECTION DOWN. IF UNIT IS TO BE SET AFTER MOUNTING, VERIFY

THAT ADJUSTMENT OPENING IS ACCESSIBLE. “FRONT” MARKING ON NAMEPLATE MUST

FACE THE OPERATOR.

1/2” NPTM or M20 Electrical Connection

When panel mounting, mount through 7/8” clearance hole in panel. Hold

in place with serrated 1/2” or M20 conduit nut. Always support the unit by

holding a wrench on the hex.

TO ATTACH CONDUIT CONNECTION, HOLD ELECTRICAL CONNECTION STEADY WITH WRENCH ON

HEX, THEN THREAD ON CONDUIT.

Surface Mounting Bracket Kit (P/N 62169-13), Option M449

Open the adjustment cover and orient the unit so that adjustment opening will be acces-

sible when the switch is mounted. Close the adjustment cover ensuring that the bracket

does not interfere with the cover. Failure to do so may result in improper sealing of

adjustment cover. Mount assembly in desired location, following instructions included with

mounting bracket kit.

WIRING

DISCONNECT ALL SUPPLY CIRCUITS BEFORE WIRING UNIT. ELECTRICAL RAT-

INGS STATED IN LITERATURE AND ON NAMEPLATE MUST NOT BE EXCEED-

ED. OVERLOAD ON A SWITCH CAN CAUSE FAILURE ON THE FIRST CYCLE.

EXTERNAL GROUNDING SCREW (OPTION M460) IS REQUIRED FOR NON-

METALLIC CONDUIT SYSTEMS.

WIRE IN ACCORDANCE WITH LOCAL AND NATIONAL ELECTRICAL CODES. BY

THE INSTALLATION, THE WIRES SHALL BE PROTECTED AGAINST MECHANI-

CAL DAMAGE. E.G. BY USE OF A CONDUIT.

DIN CONNECTOR (OPTION M515) IS NOT APPROVED FOR CLASS I, DIV.

1/HAZARDOUS LOCATIONS/FLAMEPROOF ATMOSPHERES.

THE WIRING TO THE PRESSURE SWITCH MUST ONLY BE CONNECTED IN THE

SAFE AREA OR BY AN APPROVED TERMINAL BOX CERTIFIED TO EN 50 018

OR EN 50 019 FOR HAZARDOUS LOCATIONS/FLAMEPROOF ATMOSPHERES.

1/2" NPTM or M20 conduit connection is provided on top of the unit with 72” lead-

wires. Unit is available with SPDT or DPDT operation. External grounding screw and

clamp is provided with option M460.

Factory Sealed Leadwires are color coded:

TERMINALS

SPDT DPDT

SWT1 SWT2

Common Brown Brown Yellow

Normally Closed Red Red Black

Normally Open Blue Blue Violet

Ground Green Green

DIN Connector with 4 Male Terminals (figure 3)

Wire in accordance with local and national electrical codes. Connector conforms to

DIN 43650. Use a mating DIN connector (female type). Coding:

TERMINALS

Terminal #1 Common

Terminal #2 Normally Closed

Terminal #3 Normally Open

Ground

IM12-03

Spectra 12 Series

Explosion Proof, Pressure and

Differential Pressure Switches

Part I - Installation

figure 1

DO NOT TURN

SWITCH HOUSING

MOUNT VIA

PRESSURE

CONNECTION

Please read all instructional literature carefully and thoroughly before starting. Refer to the final page for the listing of

Recommended Practices, Liabilities and Warranties.

UNITED ELECTRIC

CONTROLS

Installation and Maintenance

Instructions

figure 1