Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Important

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Operator Instructions

Manufacturer/Supplier Product Type RPM

Cycles Per Min

Model No/Nos Serial No

Product Nett Weight

lbs

Kg

Recommended Use Of

Balancer Or Support

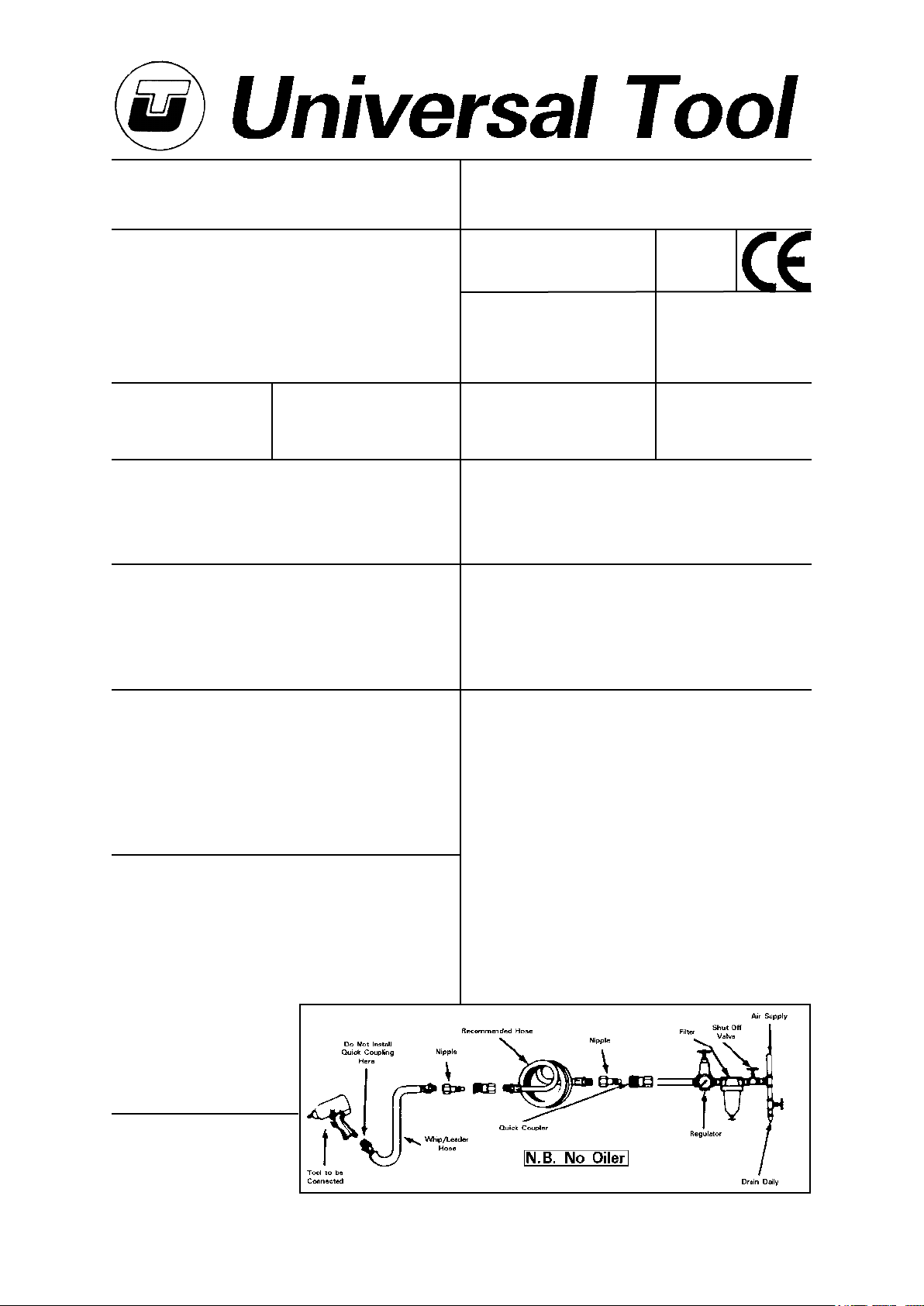

Recommended Hose Bore

Size - Minimum

Recommended Max.

Hose Length

Ins M/M Ft M

No

Page No 1

Spray Gun - Gravity Fed

Cup capacity 600 cc

UT58A-14 1.4mm

UT58A-17 1.7mm

Nozzle Size

1.32

0.60 5/16 8 30 10

N/A

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Work Stations

The spray gun should only be used as a handheld hand-operated

device. It is always recommended that the spray gun is used when

standing on the solid floor. It can be used in other positions provided the

spray gun is kept near vertical and the operator has a firm grip and

footing. Any work station must take account that the liquid being

sprayed should not be breathed in and the liquid can be highly

flammable and spraying should never be undertaken near naked flames

or hot surfaces. Do not smoke. It

should also takeaccount that not all of

the liquid being sprayed will be

applied to the object being sprayed

and account must be taken that this

surplus, i.e. “over spray” will be

deposited in the surrounding area.

Foreseen Use of Tool

This tool is an external mix, high capacity spray gun, designed for high

quality production spraying of paint and other finishing material from a

gravity plastic cup.

The material inlet is located directly on the top of the spray gun and the

air inlet is located at the bottom of the spray gun handle.

The fluid control knob and the air control knob are both located at the

rear of the spray gun, the pattern control knob is located at the left side

of the spray gun.

Tel No Fax No(01494) 883300 (01494) 883237

Noise Level Sound Pressure Level TBA dB(A)

Test Method Tested in accordance with ISO

Standard 3744

Sound Power Level TBA dB(A)

N/A

Vibration Level

Test Method Vibration testing not required for a

spray gun

N/A Metres / Sec²

Operating

Prior to shipment, this gun was

treated with an anti corrosive agent,

before using this gun make sure that it is carefully flushed with thinners.

To use the gun, tighten the air cap with its stamping number in an

upward direction. Attach material cup to the gun. Attach an air supply

line to the ¼” BSP air inlet. Check for the correct tightening of nut (4) so

that no air will escape but air valve stem (13) still slides. Caution:

Never point spray gun at yourself or any other person. Accidental

discharge of material may result in serious injury. Adjust air pressure to

spray gun. Caution: Do Not exceed 100 psi. Depress spray gun

trigger to spray material. To adjust the amount of material released

(density of fan spray), turn the fluid control knob (15) (counter clockwise

to increase, or clockwise to decrease). To adjust the width of fan spray,

turn the pattern control knob (7) (counter clockwise to increase, or

clockwise to decrease). To adjust the air quality turn the Air Volume

control knob (18) (counter clockwise to increase, or clockwise to

decrease). Note: Care should be exercised when handling spray gun

to avoid damage to the orifice of the air cap and tip of fluid nozzle,

damage to these parts will result in irregular spray patterns

Personal Safety Equipment

Use - Safety Glasses

Yes

Use - Safety Gloves

Yes

Use - Safety Boots

Use - Breathing Masks

Yes

Use - Ear Protectors

Air Pressure

Recommended Working 4.14 bar 60 psi

Recommended Minimum n/a bar n/a psi

Maximum 4.83 bar 70 psi