INTRODUCTION

Thank you for purchasing the Univex Perfect Peeler. The Perfect Peeler MP-100 is the world’s most

perfect melon peeler. The MP-100 allows you to produce perfectly peeled melon halves in a matter of

seconds with minimal handling of the edible fruit.

The MP-100 is equipped with two interchangeable peeling knives that will peel melons from 4 inch

wide to 7 inch wide. The MP-100 is not limited to the length of any particular melon, but the width or

diameter of the melon to be peeled must be between 4 and 7 inches. This size range spans melons from

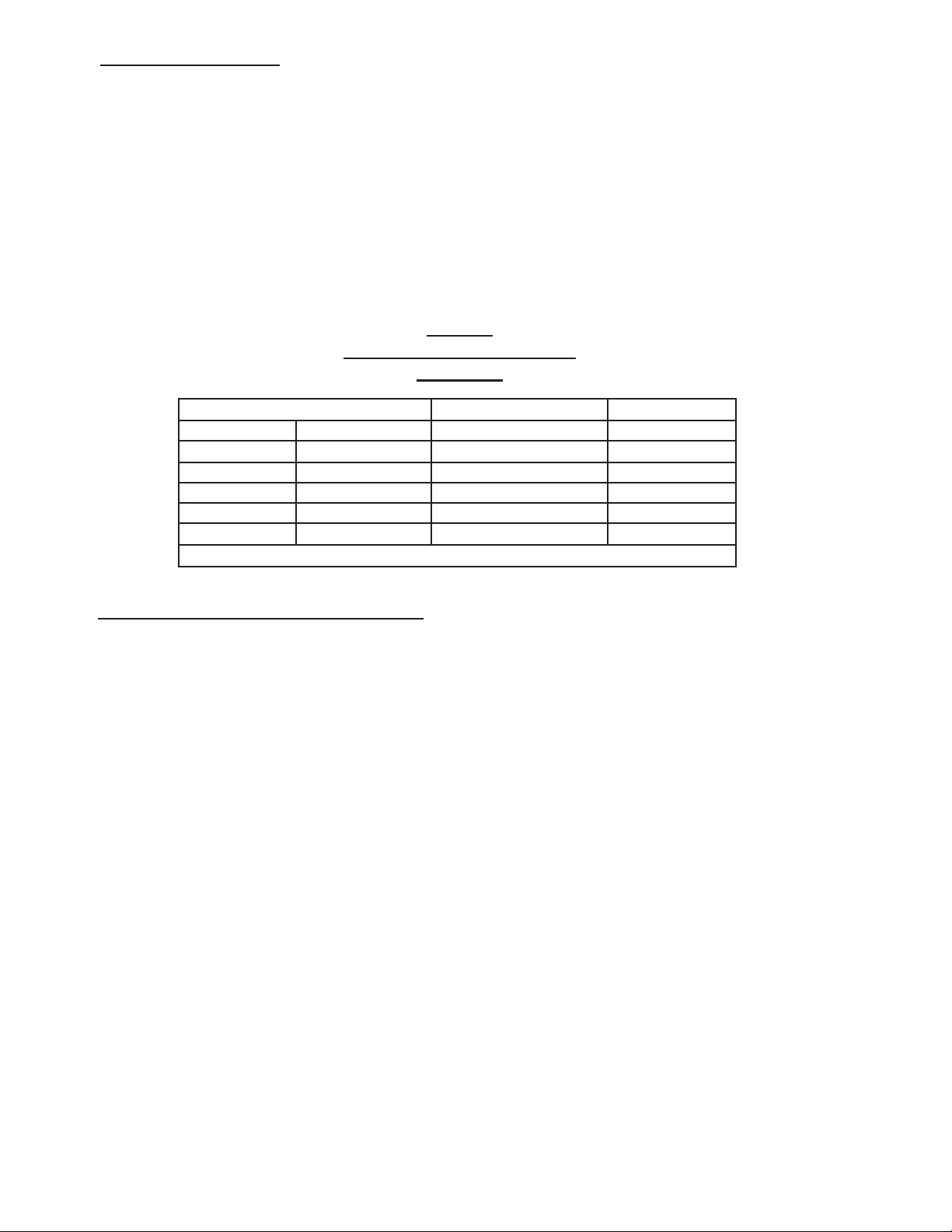

No. 5 Count Honeydew to No. 18 Count Cantaloupe. Refer to page 5, Process Section 2 Melon Sizing

and Knife Selection.

The MP-100 is safe and simple to operate, increases the yeld of edible fruit over hand peeling

methods, is 4 to 5 times faster than hand peeling and it is easy to clean. In addition, reduced handling

results in less bruising, thereby extending the shelf life of the peeled fruit.

The finished product of the Perfect Peeler cannot be duplicated by hand peeling and allows chefs to

present their customers with creative presentations of melons not possible before the Perfect Peeler.

INSPECTION

All Univex MP-100 Perfect Peelers are inspected prior to packaging to assure the quality of the

machine. However, upon unpackaging the machine, all items should be carefully inspected and verified

that they are correct. Any damage, imperfection, or shortages should be reported immediately to your

dealer or directly to the Univex Customer Service Department, and /or the shipping carrier.

OPERATOR SAFETY

• Read and understand all instructions and safety warnings prior to operating the unit.

• Never put fingers or any utensils in the entry of the peeler or in the knife area of the peeler.

•CAUTION: The knives are sharp and can cut fingers; the center head pins are sharp.

• Always fully assemble the machine before using it.

INSTALLATION

The Univex MP-100 Perfect Peeler is a table-top unit designed to be mounted and used on a table.

Make sure that a comfortable working clearance is provided around the machine for safety and ease of

operation and that the machine is installed where it will save the operator steps. Proper location should

include space for the melon collection container. Determination of where the MP-100 Perfect Peeler will

be placed during operation should take into consideration, the flow of the whole melons, the placement

of the peeled melons and the disposal of the waste skin and seeds.

Page 2