- 1 -

Contents

Welcome ........................................................................................................................................................................... 3

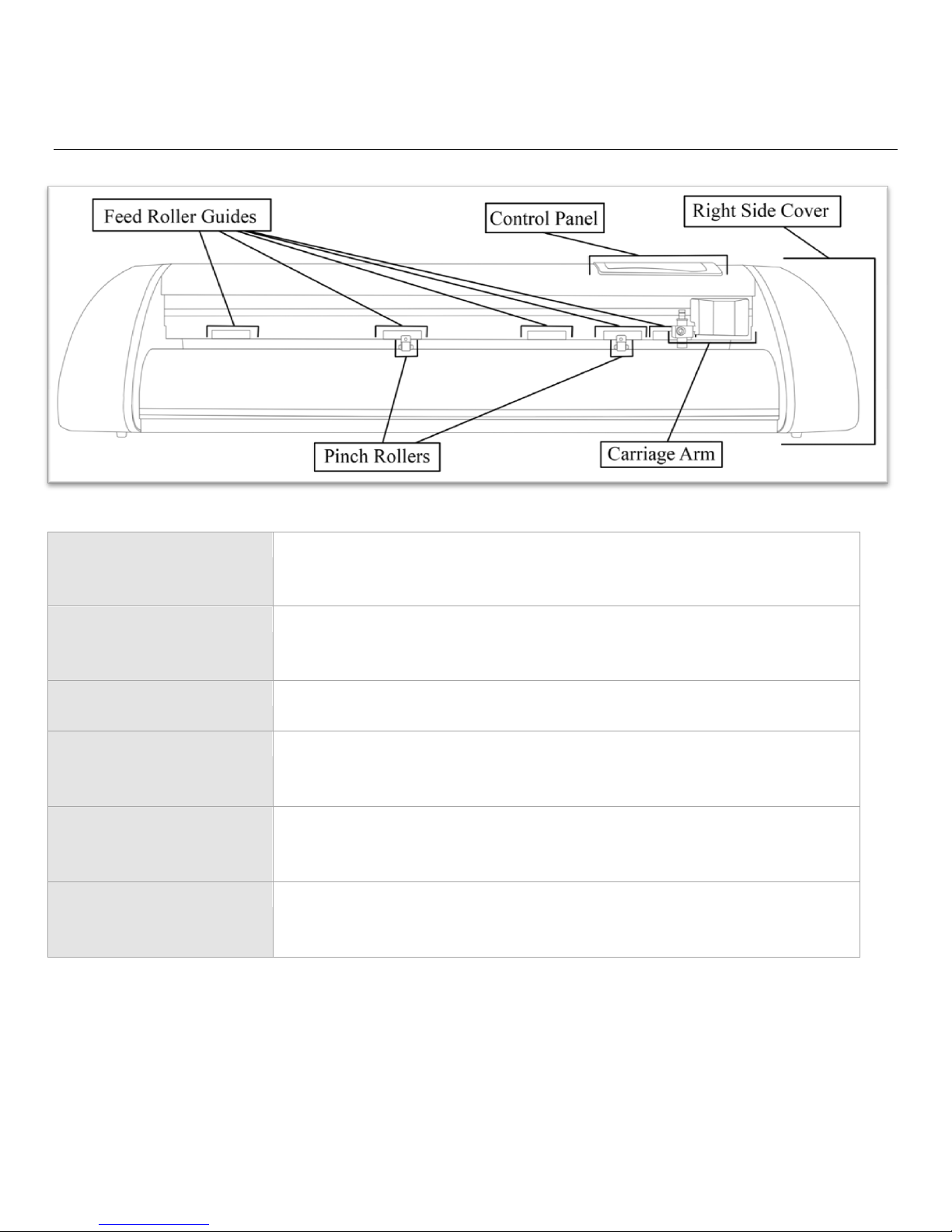

Cutter Parts ...................................................................................................................................................................... 4

Front View ...................................................................................................................................................................... 4

Detail of Carriage Arm ................................................................................................................................................. 5

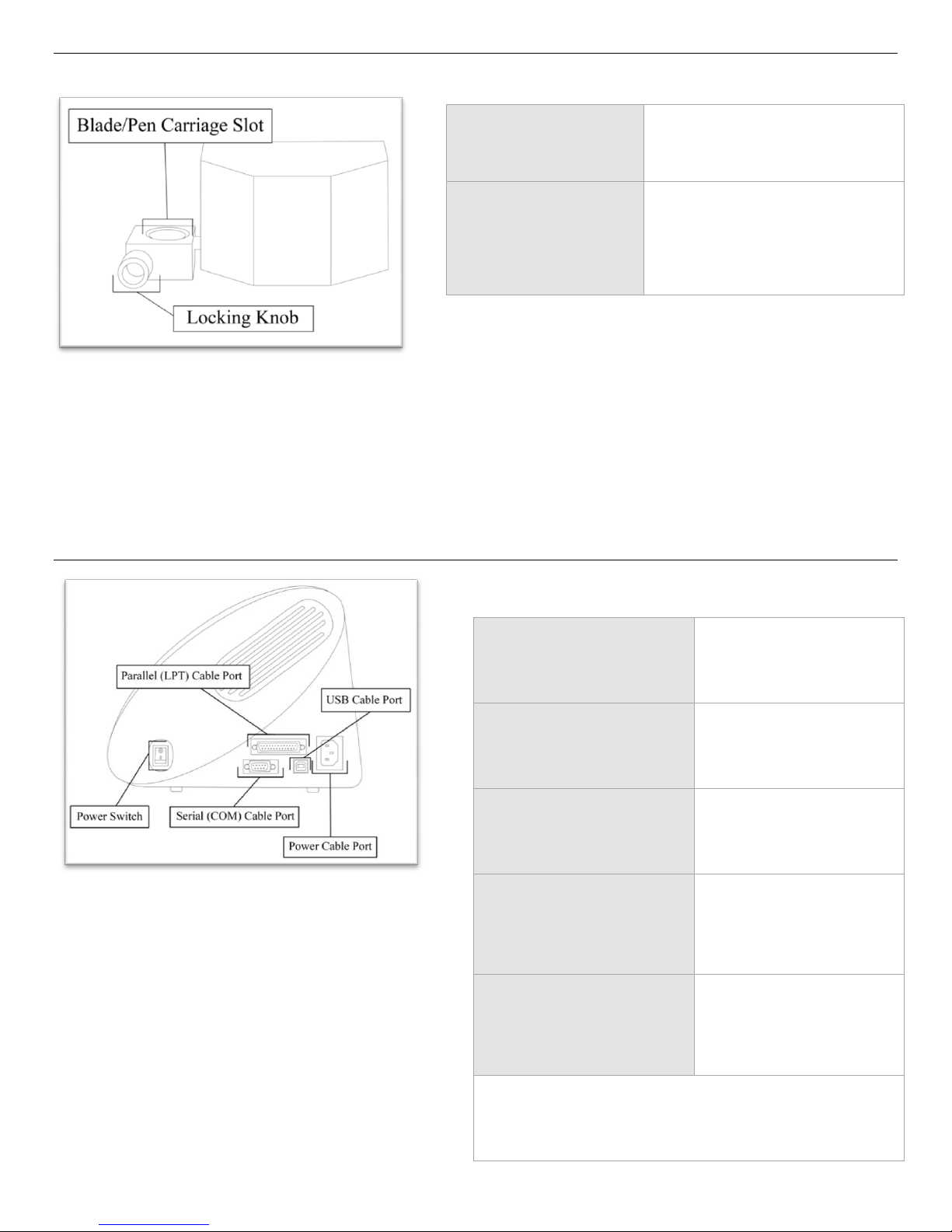

Right Side View .............................................................................................................................................................. 5

Back View ........................................................................................................................................................................ 6

Detail of Pinch Roller ................................................................................................................................................... 6

Control Panel .................................................................................................................................................................. 7

Measure Screen .............................................................................................................................................................. 7

Paper Size Screen ............................................................................................................................................................ 7

Function Select Screen .................................................................................................................................................. 8

Setup Screen .................................................................................................................................................................... 9

Jog Screen ...................................................................................................................................................................... 10

Pause Screen .................................................................................................................................................................. 11

Setting up ....................................................................................................................................................................... 12

Selecting a Location for the Cutter .......................................................................................................................... 12

Connecting the Cutter to a Computer .................................................................................................................... 12

Installing SignBlazer Software ................................................................................................................................... 14

Installing SignCut Software ........................................................................................................................................ 15

Installing a New Blade ................................................................................................................................................. 16

Replacing a Worn Blade ............................................................................................................................................. 17

Installing a Pen Carriage ............................................................................................................................................. 18

Preparing for Cutting .................................................................................................................................................. 20

Step By Step Instructions ....................................................................................................................................... 25

Starting SignBlazer for the First Time ...................................................................................................................... 25

Making a Simple Cut in SignBlazer .......................................................................................................................... 27

Importing in SignBlazer .............................................................................................................................................. 29

Converting a Raster Image to Vector Image in SignBlazer.................................................................................. 32

Starting SignCut and Inkscape for the First Time ................................................................................................. 35

Creating a Simple Design in Inkscape....................................................................................................................... 37