(1) When operating the machine, keep alert at all times. Do not use the machine in the state of

fatigue, alcohol, drugs or drug treatment, so as to avoid accidents caused by inattention during

operation

(2) During operation, please use protective equipment, such as dust mask, goggles, earmuffs, etc.,

to prevent splashing sand and dust from hurting eyes, face or hearing due to strong noise

(3) Avoid accidental start-up. Before turning on the power, make sure that the switch of the

machine is off. After confirming that there is no mistake and connecting the power supply, do not

immediately put your finger on the button of the switch to prevent accidents.

(4) Before starting the machine, also check that the adjusting lock wrench and tools are

disengaged from the machine.

(5) During operation, the body should not stretch forward excessively, please keep the balance of

the body at all times

(6) During operation, please do not wear loose clothes or hand ornaments. Users with long hair

should put their hair into the protective cap to avoid touching moving parts and causing

accidents

5、Use and precautions of the machine:

(1) Check the safety of the power supply before use. Poor socket and power cord may cause poor

contact, which is serious ,It may cause electric shock, fire and other accidents;

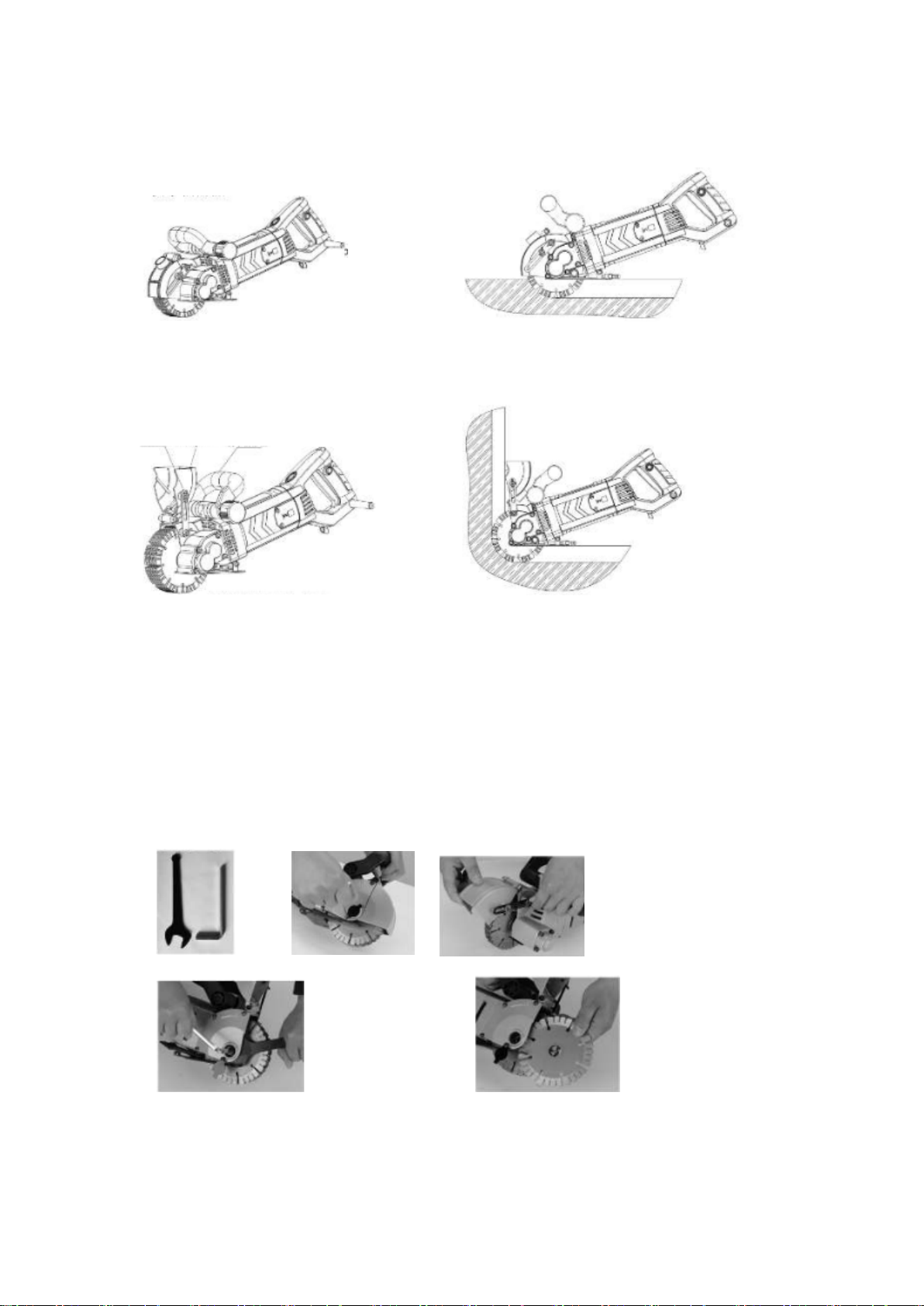

(2) In slotting operation, it is necessary to keep straight and constant speed, so as to maximize

cutting efficiency

(3) The operator shall wear insulated gloves and insulated shoes when using the cutting

operation with water, so as to avoid touching Occurrence of electric accident

(4) The efficiency and accuracy of slotting can be improved by marking the guide line on the

working surface

(5) This machine is a high-power cutting tool, and the load is heavy during the working process.

Therefore, each joint should be checked before use,Only when the connecting parts are firm and

reliable can they be used;

(6) In case of no water cutting operation, dust removal equipment shall be equipped additionally,

so as to ensure a good working environment

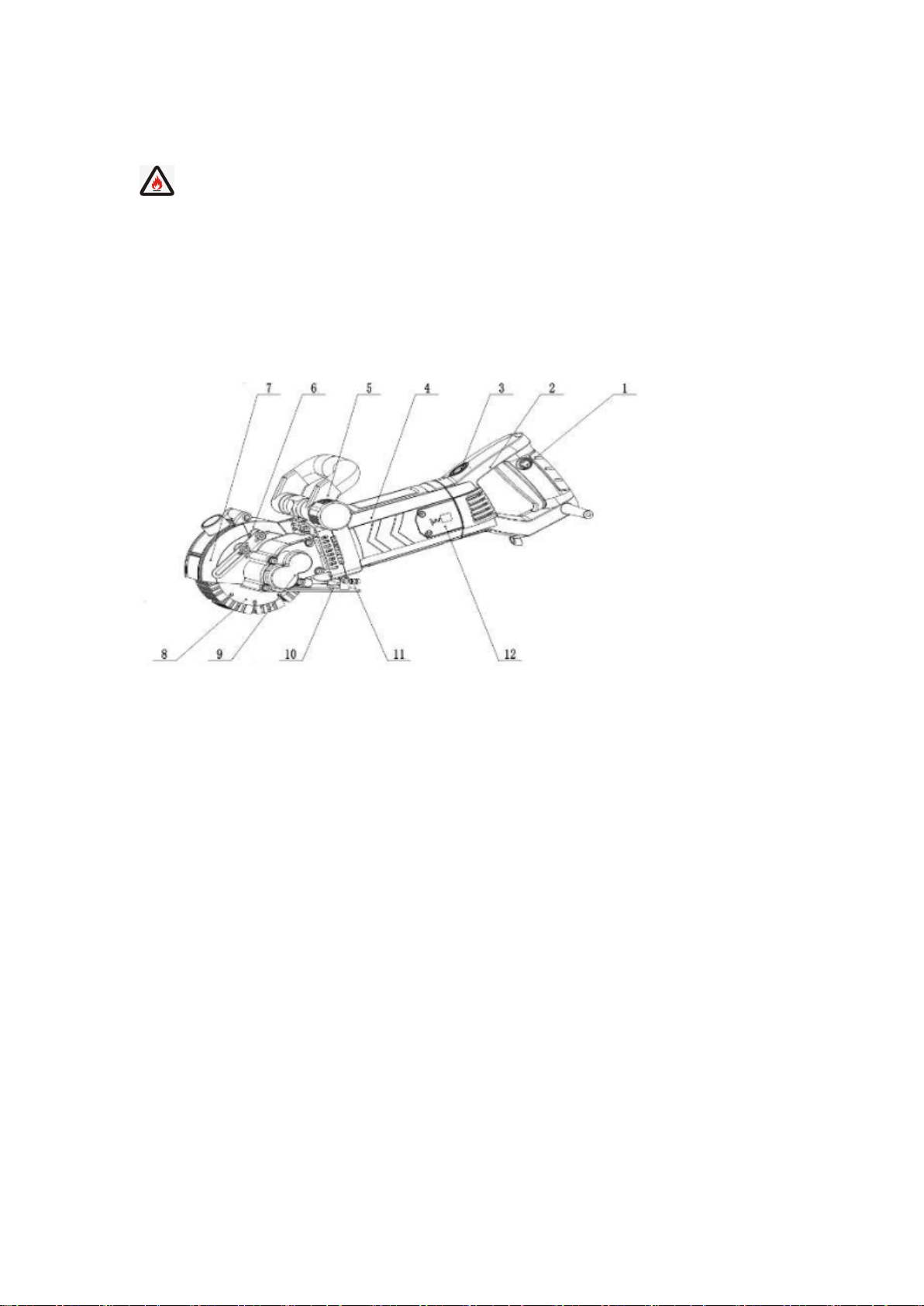

(7) When cutting the corners of the machine, open the shield, pay special attention to the

prevention of flying sand It is very dangerous to carry out slotting operation without protection,

which will cause personal injury in serious cases.

(8) When using the water pump to slot the wall, please pay attention to opening from top to

bottom, and do not let the water flow Into the fuselage.