4

Site Selection & Preparation

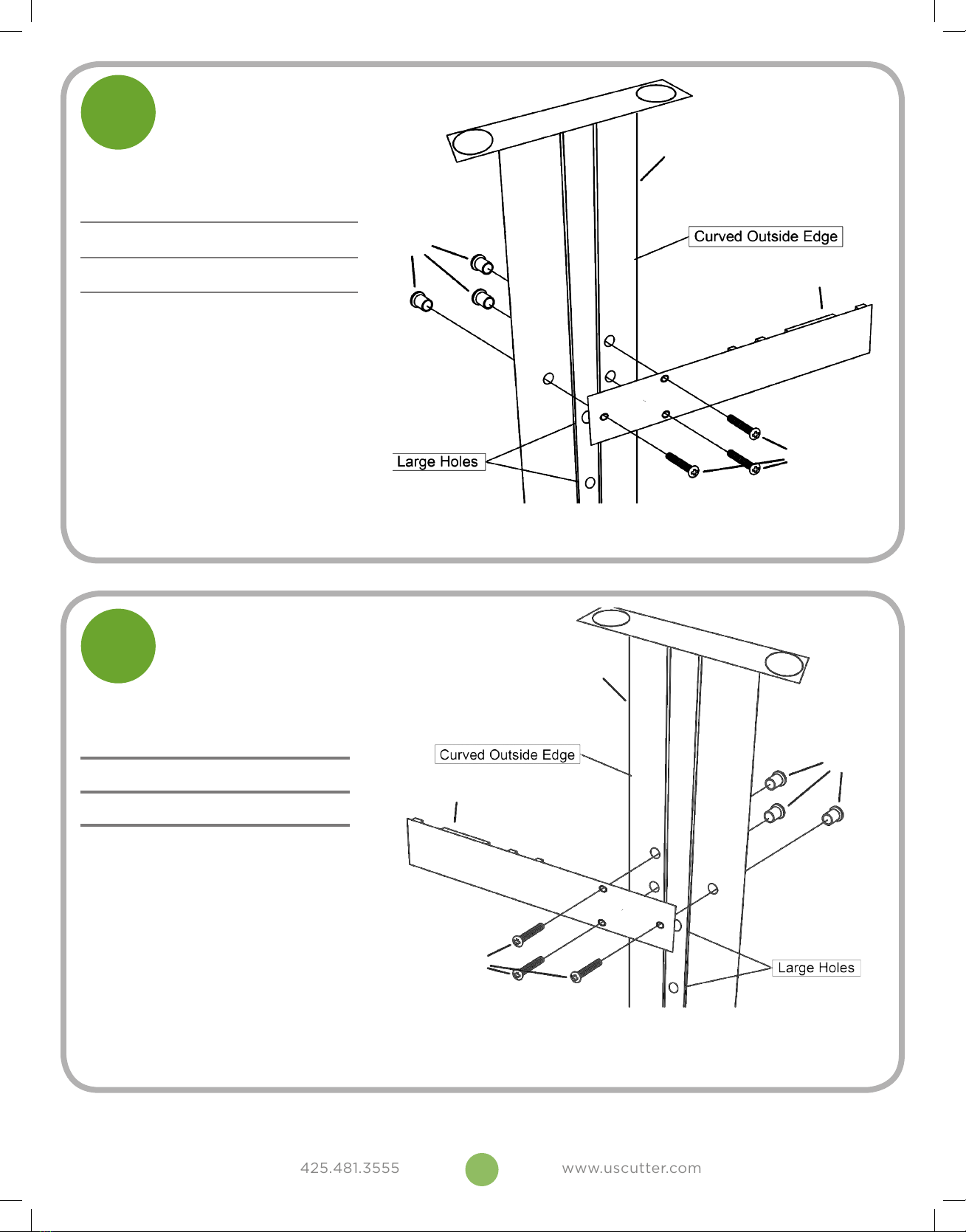

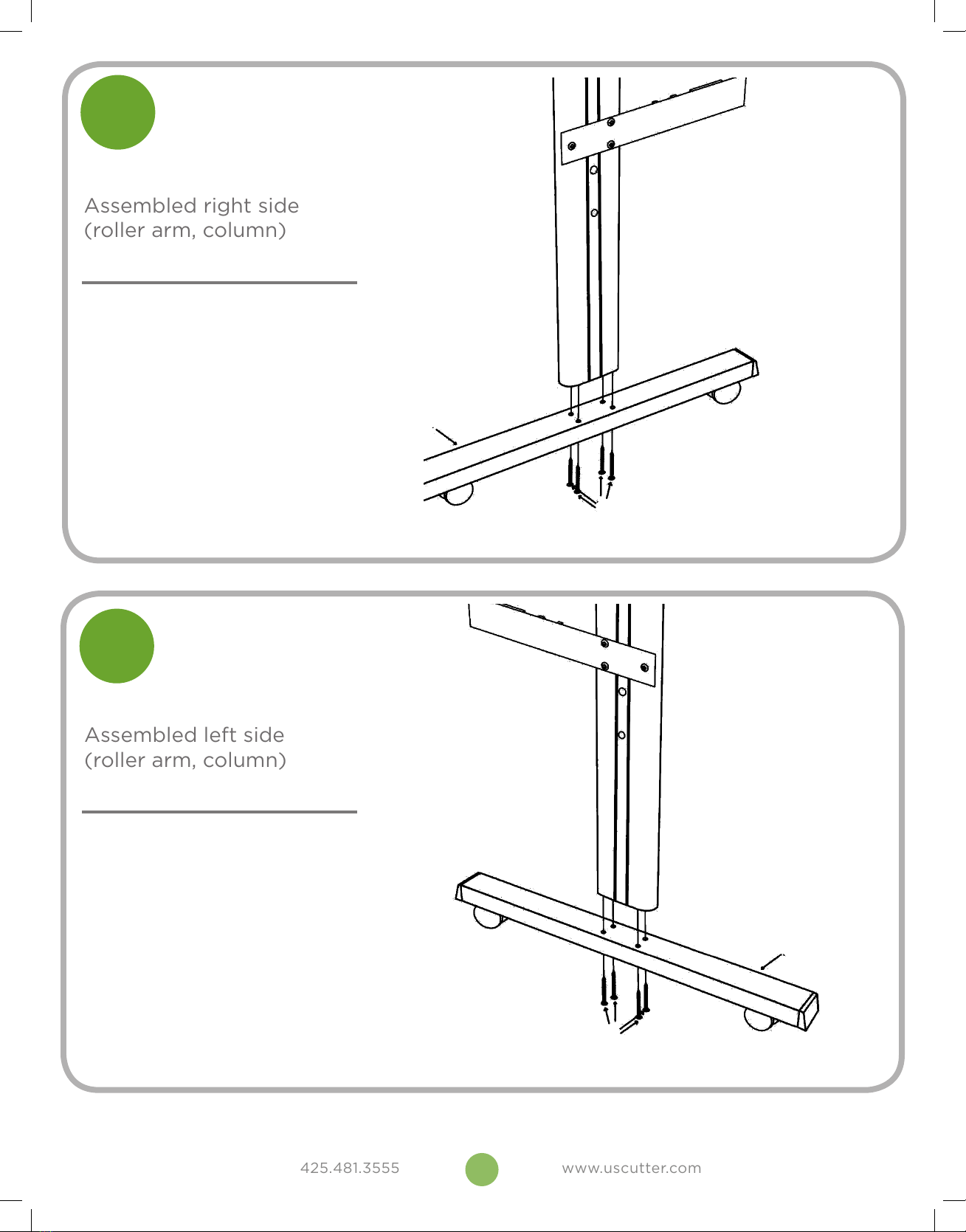

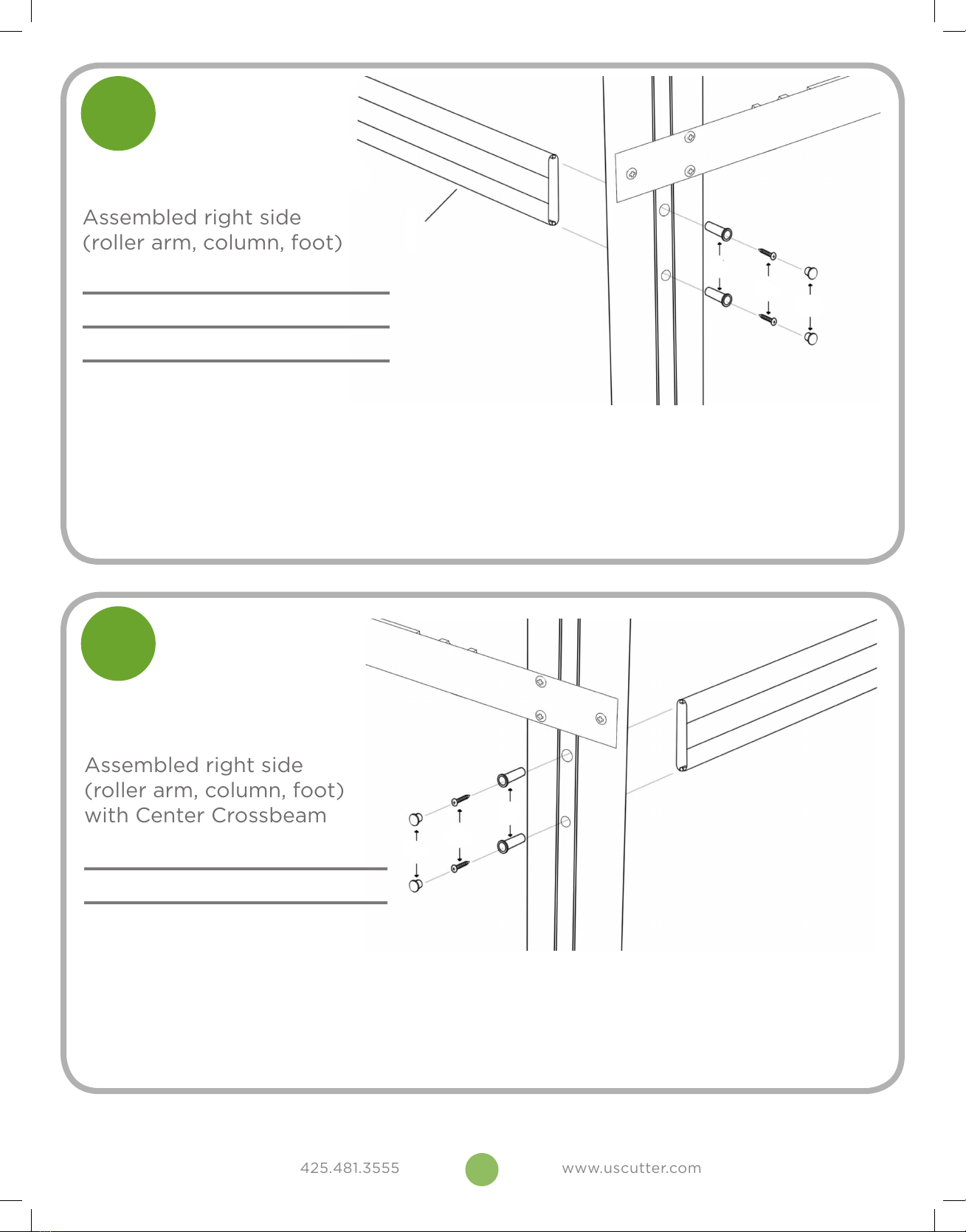

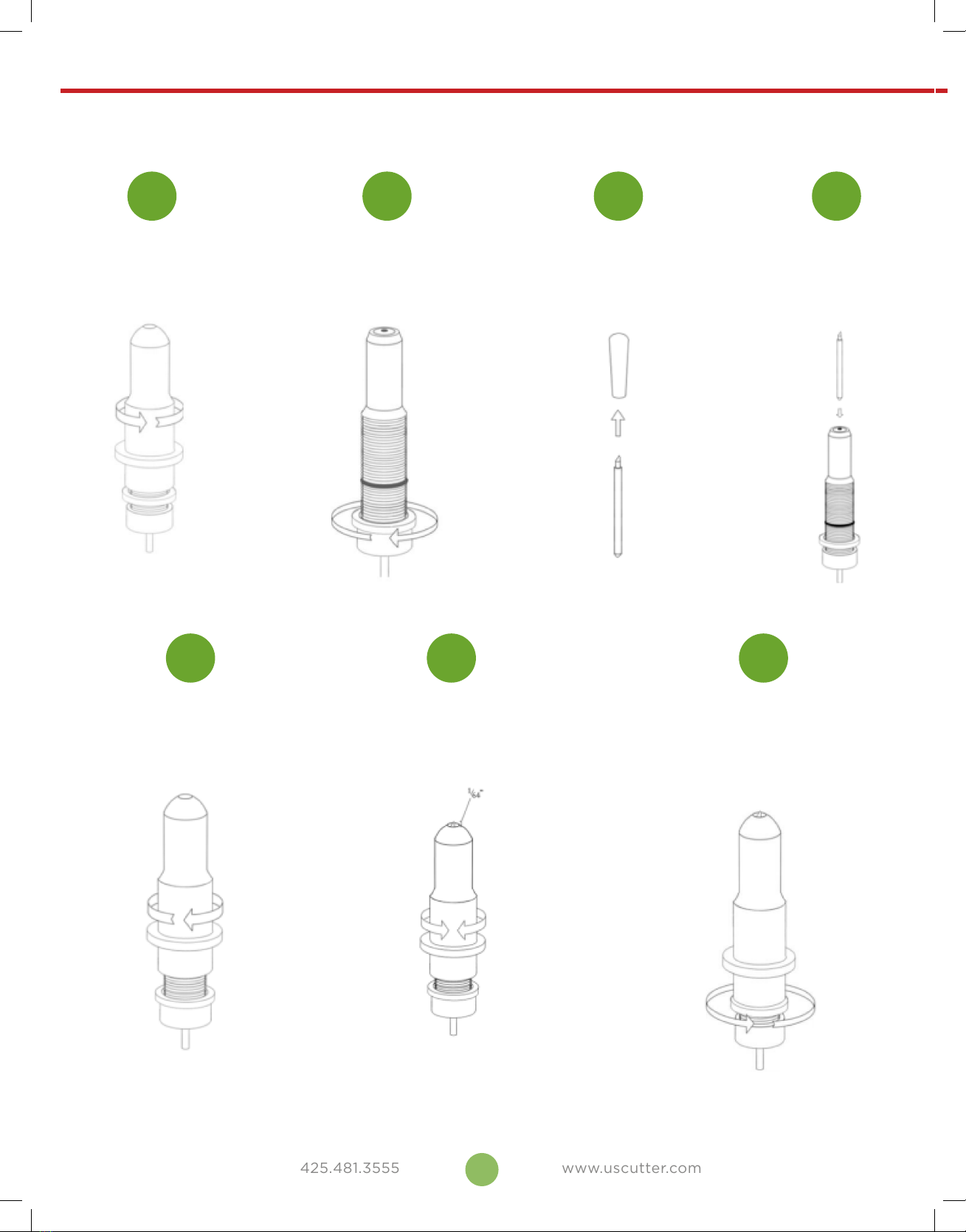

If you are setting up for the first time please take a moment to refer to the Packaging Guide to

take account of all the included components and accessories. For help with Stand Assembly,

please refer to included instructions.

The first step to setting up your cutter is finding

a good location for the machine. Consider these

factors when you are selecting a suitable place:

Stability is key. Your MH cutter is a precision cutting device and the carriage head will move

quickly back and forth across the vinyl. If it vibrates due to an uneven or unstable surface,

it will result in issues with your cut. Whether placing the machine on a stand or table top,

choose a level and stable surface.

All cutters will produce a small amount of noise while operating. Please take this into

consideration when selecting a location for your cutting purposes.

Fans located inside of the cutter can draw in outside dust from the area surrounding the

cutter. Excessive buildup of dust can cause either mechanical or electrical malfunctions.

Keeping the cutter as dust free as possible will help ensure trouble free operation. Try to find

an area for the cutter that will be free of any excessive dust and use the supplied cover when

not in use.

A 110 outlet with a grounding plug is required for operation of the vinyl cutter/plotter and you

will want internet access for our PC in order to download software and drivers required for

operation. DO NOT attempt to use the cutter when it has not been properly grounded.

You will need to have access to both the front and rear of the machine for operation and

changing out of vinyl rolls. Find a space that has adequate access and where the roll can roll

freely on the rollers or on the table top.

Place your cutter near the PC that will be used to drive content to the vinyl cutter.