20 21

Laser centered on registration dot

Contour Cutting Contour Cutting

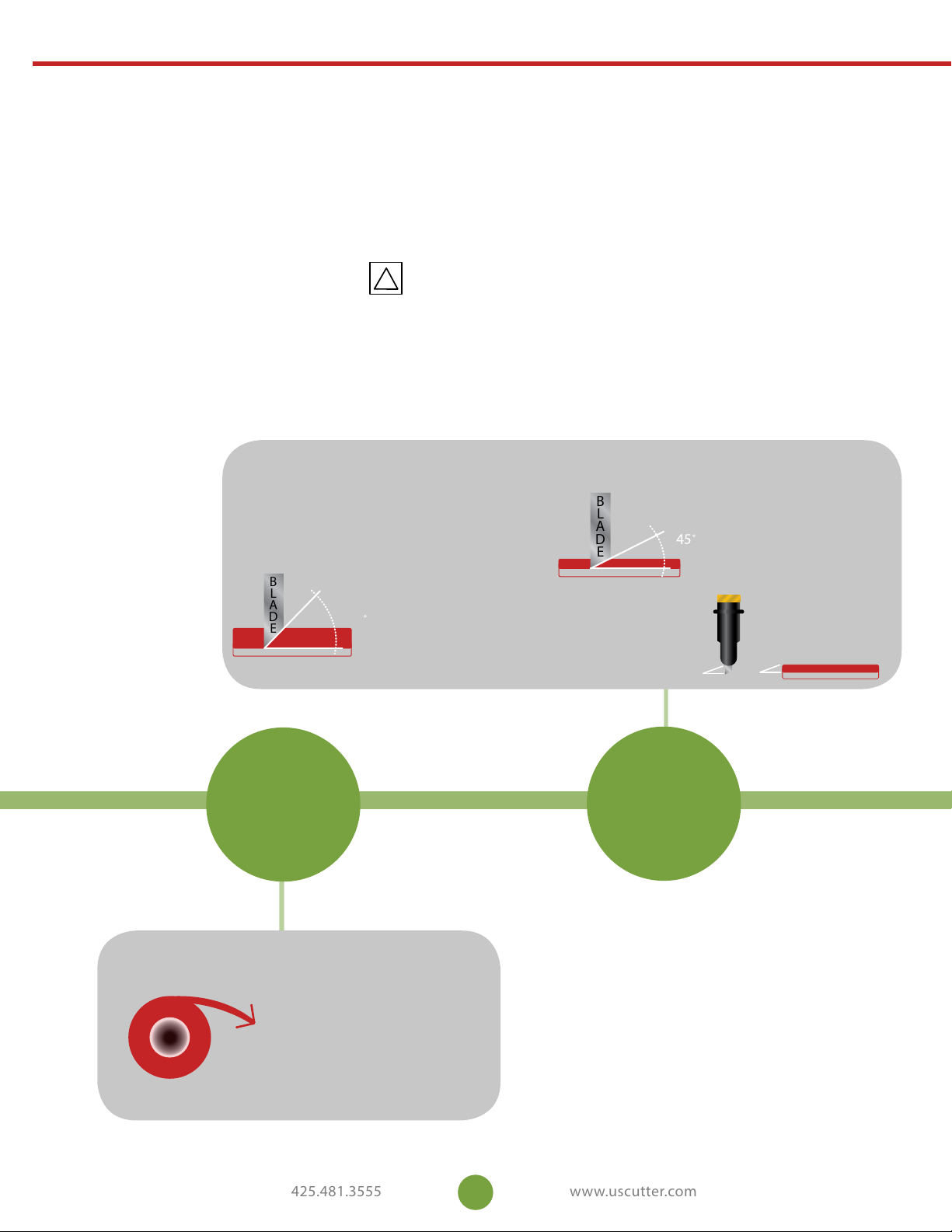

1Calibrating the laser

Press “Enter” and use the arrow buttons to place the

carriage over a piece of paper. Insert plotter pen and

make an impact on the paper by pressing down and

twisting the pen cartridge.

Turn the cutter’s laser on by pressing the “Select” button

to highlight the word “On” and press “Enter”. e

cartridge and the paper should move immediately and

the laser should be exactly centered on your pen mark.

is shows that the oset between the laser and the pen/

blade is properly calibrated. If your laser doesn’t line

up exactly with the mark, your cuts will not land in the

proper lacation and you will need to adjust the oset.

2Testing the laser oset

Start by placing the test paper ush against the right side

of the cutter and secure the pinch rollers. Hold down the

“Right” arrow and ress the “Reset” button or simply turn

the power o and then back on. If you are successful you

should see the word “OK” on the start up screen. If you

do not see the word “OK” repeat resetting the machine

until you do. Next, make a new impact mark with the

pen. Use the arrows to center the laser directly over

the pen mark and press the “Enter” button. Re-test the

laser oset by repeating step 2. Once you have nished

calibrating your laser it’s time to print your image.

Adjusting the oset

3

4Printing your image

Load your image into the “Sure-Cuts_Allot” soware.

Make sure your art is centered and the size of the cutting

mat in your soware is the same size as the media you

are going to be using. Double check that you have the

correct printer selected by going to “File”, and select

“Print”. Select your printer and make sure you have

checked the box that says “Print Registration Marks”.

Press “OK” to send the job to your printer. You should

now have your printed image with three numbered

registration marks at the corners. Now back to your

cutter for the nal step.

5

Load your image with the registration mark number

“1” in the upper-le hand corner. Now set the position

of the pen/blade infront of, and to the right of your

printed image. Specically infront of the registration

mark. is insures the cutter has enough room to nd all

the registration marks located on the media. To set the

position, press “Enter” with “Local” highlighted and use

the “Arrow” keys to position the carriage. When the pen

is in it’s proper place press “Select” to highlight the word

“On”, and press “Enter”. Now use the “Select” button to

highlight the word “Current” and press “Enter”. e laser

will now be on and the cutter is ready. In the Sure-Cuts-

Allot soware, click on the scissors icon to open your cut

settings window. Click on “Print and Cut” option and

click the “Next” tab twice. e cutter will move from it’s

current position to registration mark number “1”. Don’t

be alarmed if it stops short. Using the keys on your

computer’s keyboard, center the laser over the dot in the

registration mark, then click “Next”. e cutter will move

towards registration mark number “2”. Again, center the

laser over the dot using your computer’s keyboard and

click “Next”. Repeat this process for registration mark

number “3”. Click the “Cut” button and the cutter will

briey return to it’s home position and complete the cut.

Registering prints with the cutter

Flush on right edge

Laser centered

Pen Mark

18 19