7DEOHRI&RQWHQWV

33HAC 16578-1 Revision: E

© Copyright 2003-2007 ABB. All rights reserved.

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

*HQHUDOLQIRUPDWLRQ

1.1 To what robots does this apply? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 When to calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Types of calibration procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Calibration scales and correct axis position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

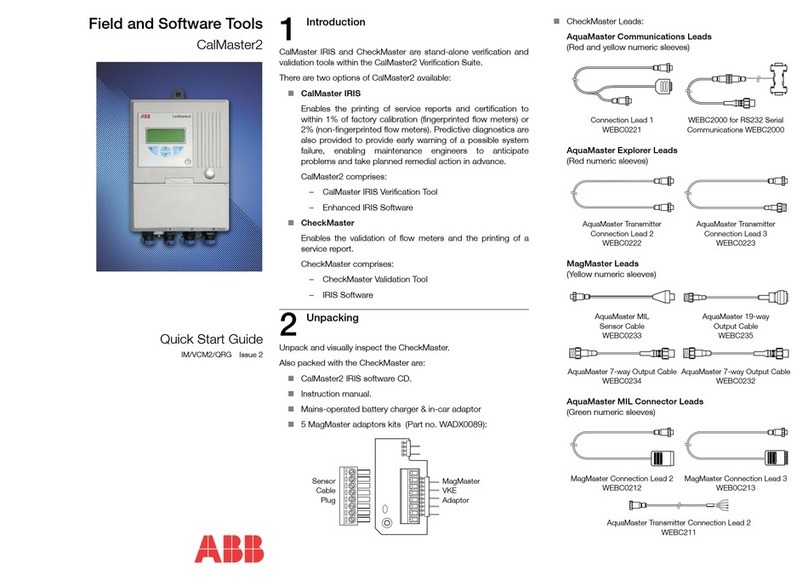

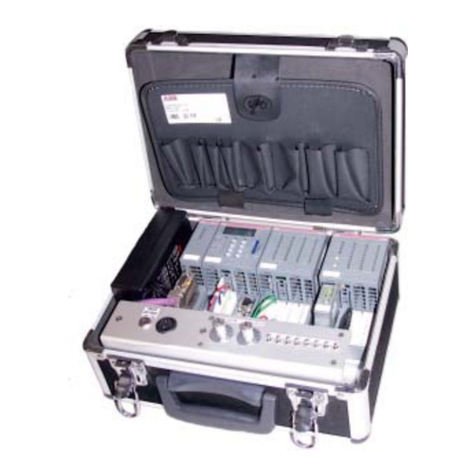

1.5 Equipment for calibration pendulum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.6 Storage and warm up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3UHSDULQJWKHHTXLSPHQW

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Start up of Levelmeter 2000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3 Calibration of sensors (calibration pendulum) and Levelmeter 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.4 Checking of sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

&DOLEUDWLRQ

3.1 Different functions in the calibration service routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

&DOLEUDWLRQ3HQGXOXP,,

3.2.1 About Calibration Pendulum II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2.2 Preparing the calibration procedure, CalPend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.3 Calibration, all axes, CalPend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2.4 Updating revolution counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2.5 Calibration sensor mounting positions, CalPend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.2.6 Preparation for using sensor on axes 1 and 6, CalPend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.2.7 Calibration Pendulum II procedure on TPU, S4Cplus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.2.8 Calibration Pendulum II procedure on FlexPendant, IRC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.9 Post calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.10 Checking the calibration position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5HIHUHQFH&DOLEUDWLRQ

3.3.1 About Reference Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.3.2 Preparation of reference surface at tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.3.3 Defining reference values for calibration of axes 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.3.4 Preparing the calibration procedure, RefCal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.5 Calibration of axes 2-6 using predefined reference values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

,QGH[