V-GREAT VG-6728 User manual

1

VG-6728 Pulse Interface Installation Manual

(Ver1.2, Sep. 2020)

I Overview

II VG-6728 Digital Pulse Interface is designed to monitor and drive a fire-fighting equipment,

when received an order from FD&A control unit. Its principle and application is generally similar

to VG-6727 Digital Control Interface. The only difference is utilizing Pulse-drive method on

detachable equipment, such as Fire Valve, Solenoid Valve, Exhaust Fan, etc. This interface is

designed with dual-capacitors inside to provide instant energy for the activation of other

fire-fighting equipment, without need of extra power supply.

III Features

Distributed intelligent products, plug-in structure design.

With dual capacitor energy storage, and driving the equipment in a pulsed manner, the reliability is

improved.

There is no need to provide 24V operating power supply to the interface, which can reduce

construction costs.

Output terminal and the feedback terminal are provided with the function of line monitoring.

IV Technical Data

Operating voltage: DC18V-28V Standby current: ≤ 1mA

Output capacity: DC30V/2A

Acting time: 270mS. (time from activate to stop)

Temperature: -10℃~ +50℃

Humidity: ≤95%GH (40±2 ) without condensation℃

Status indication: When charging, both “Input” and “Output” indicators flash in a quick manner,

and the “Input” indicator flashes in a quick manner when fully charged; When activated, the

“Output” indicator is illuminating and the “Input” indicator is illuminating when receiving a

feedback signal; When there was fault on Output or Input, the corresponding indicator will flash in

a slow manner.

Loop wiring: Non-polarity

Maximum charging current: 4mA (when the energy of capacitors is down to zero, it is charged by

loop power);

Charging time: about 48s (the two lights flash in a quick manner when charging; the energy

storage voltage is 30V ± 2V when fully charged, and the input action monitoring light flashes

when fully charged)

2

Dimensions: 82mm×82mm×35.5mm (excluding base)

Transmission distance : ≤ 2,000m

Program: Electronic Addressing

Installation: Wall-mount, plug-in structure

Adapting base: VG-6613G

V Structure and Installation Dimensions

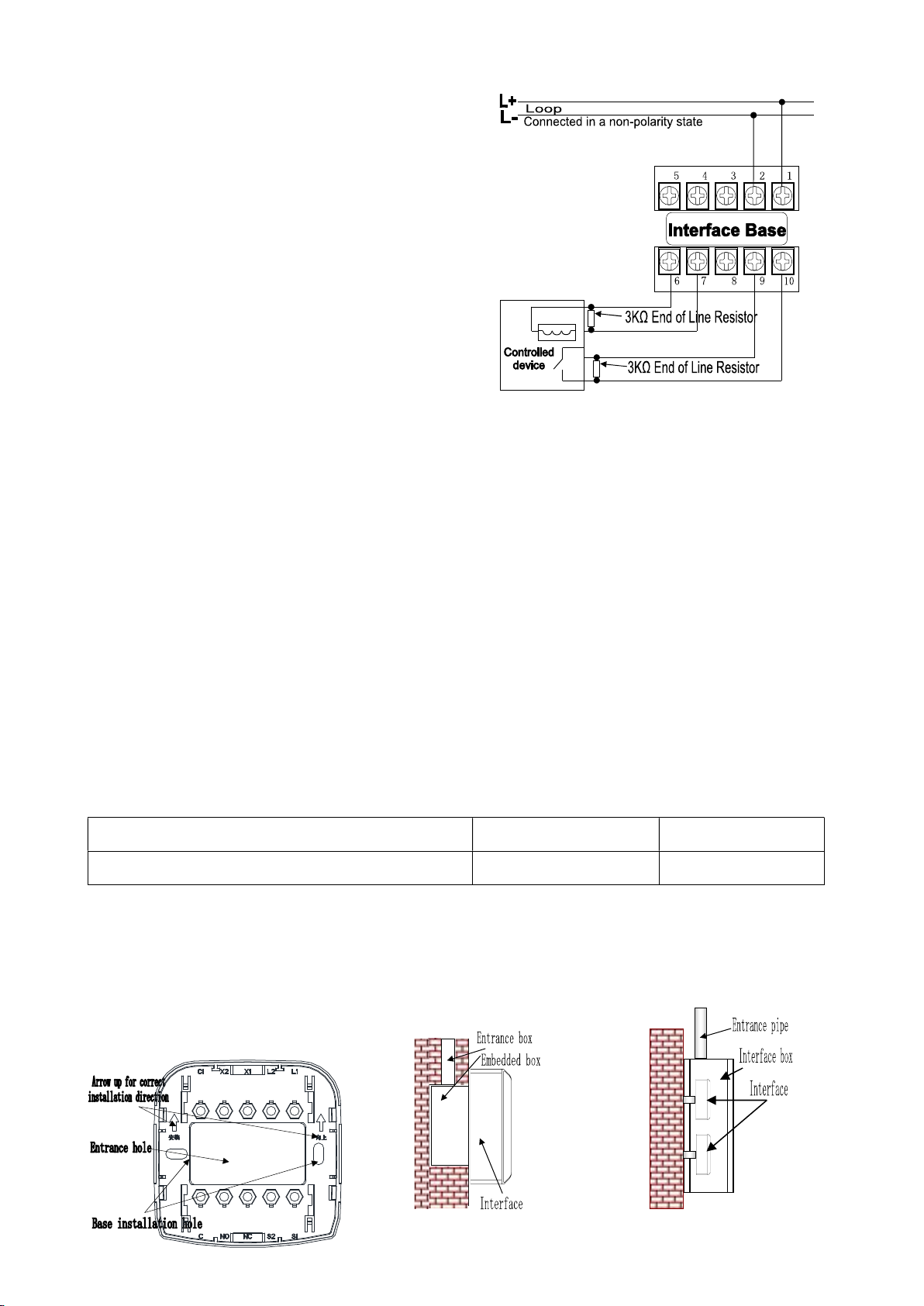

VI Wiring and Installation

Definitions of terminals:

Terminals (L1, L2): Loop Input terminal,

which is connected to the loop line (L+ and

L-) of the Digital Fire Alarm Panel as

non-polarity; it is also the terminal for

programmer;

Terminals (K1, K2): the positive and

negative activating the fire equipment, and

K1 and K2 can monitor the circuit fault;

Terminals (S1, S2): the input terminal of the

feedback signal from the fire equipment,

which receives the passive switching signal,

and monitors the feedback signal input line

for disconnection failure by detecting the

Figure (1) Dimensions Schematic

Loop Input terminal

Output terminal Input terminal

Installation

Up

Figure (2) Definition of terminals

3

3KΩ terminal resistance.

Settings of Jumper: “SI” put on Jumper

to open the function of line-fault check on

Input line, while take off the jumper to

close. “SO” put on Jumper to open the

function of line-fault check on Output line,

while take off the jumper to close.

Other functions of the interface set by using

VG-6537 Programmer: as shown in Table "1"

Engineering application passive output wiring scheme:

The wiring of the Base VB-6613G of VG-6728 Pulse Interface is shown in Figure (3);

The base terminals L1 and L2 connected to the loop as non-polarity.

The base terminals K1 and K2 connected to the passive terminals of the fire equipment.

The base terminals S1 and S2connected to the feedback of the fire equipment.

The EoL resistor 3KΩ is required on both the action and feedback terminals of the fire

equipment (if electro-magnetic type).

The interface is strictly forbidden to connect to the active type of fire equipment.

When there are 25 interfaces in the same loop, its front end should not be connected

with VG-6777 Isolate Interface, and if there are more than 50 interfaces in the same loop,

the front end shall be connected with VG-6781 Repeater Interface.

Table 1: Enter the following values after operating the 024 command of the VG-6537 Digital

Programmer

Output (interface power-on, state at reset) Input feedback Auto feedback

K2 and K1 are normally open 201 (default) 200

Construction and wiring requirements:

It is recommended to use ZG-GVS-2×1.0~1.5mm2 flame-retardant twisted-pair cable for the loop

wiring. If there are too many devices connected in the loop, it is suggested that the flame-retardant

twisted-pair cable no less than 1.00mm should be used. .

Installation:

Figure

(7) Interface

Installation Method

Figure (8) Interface

Installation Method II

Figure (3) Wiring diagram

4

Install the interface base in the position specified in the construction drawing. Please note that

the upward arrow on the interface base is the correct installation direction;

An Programmer is used to address the interface. Note: The bus devices in the same loop bus

should not have the same address code;

Install the interface firmly on the base, and

the installation is complete.

Disassembly of interface:

There are 2 openings for removing the interface on the two sides of

the joint of the interface and the base, respectively;

Insert a slotted screwdriver into the opening at an angle, and

gently pry the interface one by one to remove the interface.

For detailed steps and methods of addressing, refer to the VG-6537 Digital Programmer

Instruction Manual.

VII Handling and Storage

The transportation, handling, and storage of the Interface must be carried out in a packaged state. It

is necessary to handle in a gentle manner during loading and unloading to prevent collision damage.

The repeater should be stored in ventilated and dry places, and shall not be stored in the open.

VIII Precautions

In case that an interface failure is reported after long-term operation, it is necessary to first check

whether the interface has been damaged, or whether the installation position has changed

unexpectedly, and then consider other causes of the failure.

The staff on duty shall be proficient in the operating procedures of the equipment and disoperation is

not allowed.

The interface is a fire-fighting product. The on-duty and shift of duty system must be strictly

implemented during use, and the operation records must be maintained properly.

Functional tests should be performed on the interface every six months.

Company: V-GREAT GLOBAL CORPORATION

Add.: Second Floor, Capital City, Independence Avenue,

P.O. Box 1008, Victoria, Mahe, Seychelles

Web:http://www.vgreatglobal.com Email: tech@vgreatglobal.com

Table of contents

Other V-GREAT Recording Equipment manuals