Vacon 10 User manual

Other Vacon Controllers manuals

Vacon

Vacon 100 flow Instructions for use

Vacon

Vacon 100 INDUSTRIAL User manual

Vacon

Vacon 100 HVAC Instructions for use

Vacon

Vacon 100 INDUSTRIAL Quick start guide

Vacon

Vacon 100 flow Instructions for use

Vacon

Vacon 20 x Maintenance and service guide

Vacon

Vacon NX_ 0003 5 User manual

Vacon

Vacon 20 User manual

Vacon

Vacon 100 flow User manual

Vacon

Vacon 100X series User manual

Vacon

Vacon nxs User manual

Vacon

Vacon OPTAF User manual

Vacon

Vacon 20 CP User manual

Vacon

Vacon 100 INDUSTRIAL User manual

Vacon

Vacon NX User manual

Vacon

Vacon 20 X User manual

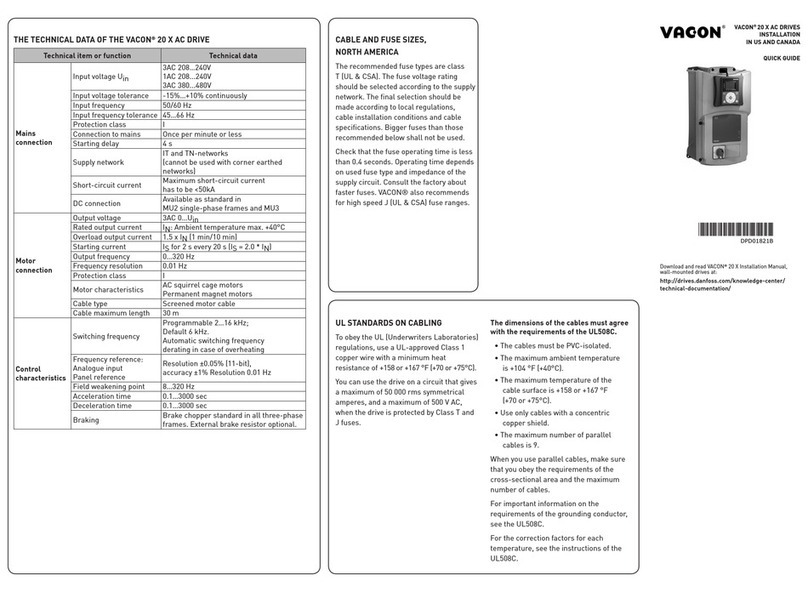

Vacon

Vacon nxsp User manual

Vacon

Vacon 100 INDUSTRIAL User manual

Vacon

Vacon CANopen OPTE6 User manual

Vacon

Vacon 100X series Manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions