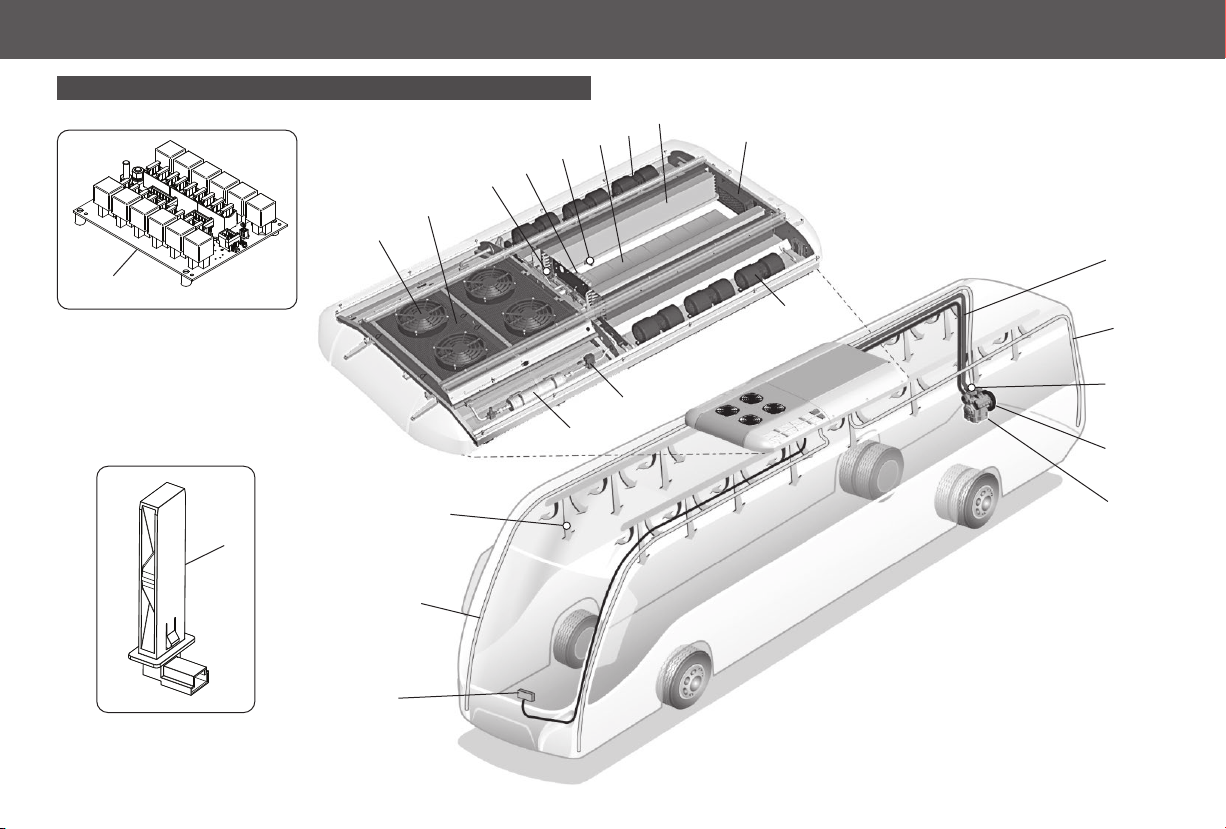

Condenser Fan

Condenser fan and the compressor will only work at

“Cool Mode”.

Refrigerant Fluid

Its main goal is dissipate the heat out, which was

absorbed by the refrigerant fluid along the

refrigeration system.

At the condenser, the overheat refrigerant fluid is

sent to outside losing its force, changing from

gaseous state to liquid state.

Condenser

Drier filter

Tiene la finalidad de retener impurezas y/o

humedad que pueda haber en el sistema

impidiendo que lleguen en la válvula de expansión.

Valve hinders the refrigerant inlet that comes from

de condenser at high pressure and its goal is adjust

the refrigerant gas flow that passed by the

evaporator looking for making the pressure steady

and temperature at the capillary tubes output.

Compressor

When it is working, the compressor sucks the refrigerant

fluid from evaporator at gaseous state and under low

pressure, compressing it, so temperature and pressure

increase, then the compressor puts it into the condenser.

MECHANIC SYSTEM

Compressor Operation

It is started up by the vehicle engine though a

pulley-and-belt system and put into action by an

electromagnetic clutch when air conditioning is

operating at “Cool Mode”.

Air refrechment

This permits the entry of the exernal in order to expel

unwanted odors and impurities from the vehicle.

Evaporator Fan

Evaporator fans are working at cool and fan modes,

fans can be set in two speeds.

Sped control can be manual or automatic.

Temperature Sensor

The interior temperature is measured by the

temperature sensor placed at the air return spot.

Pressure Switches

Pressure switches are electric devices that monitor the air

conditioning equipment operation pressure. Every time a

strong change happens from the NORMAL temperature,

they turn off the compressor immediately to avoid break.

Observation: pressures are always monitored, even if the

air conditioning is turned off.

ELECTRIC SYSTEM

Evaporators

Now at evaporators, the refrigerant fluid, at low

pressure, turns from liquid to gaseous state,

absorbing the interior heat of the vehicle in this

process.

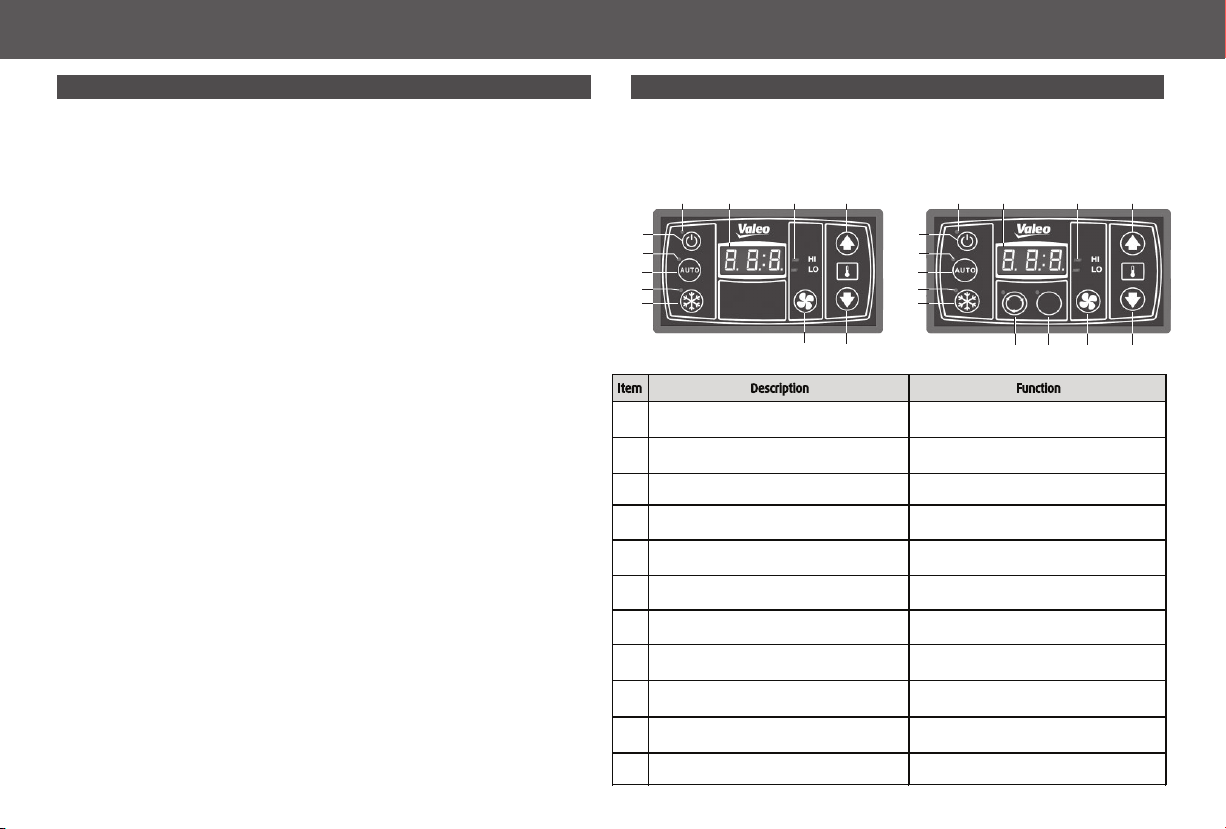

Controller

It is installed in the instrument panel, it offers to the

driver to set-point of temperature, to see by display the

interior temperature, offering full climatic control inside

de bus.

Set-point: it is the temperature the driver wishes to set

inside the vehicle for passengers.

Relay Board

Relay board has the controller controls, condenser fan

control, evaporator control and compressor control.

Air filter

Air return filter retains impurities from air avoiding

any block of dirt at evaporator capillary tubes and

coil.

Air circulation

Air being cooled by the evaporator, then it follows

to the bus interior through fans.

Drain

It is a way to get the condensed moisture from

evaporator tubes from the condensed tray to putting

out.

MECHANIC SYSTEM

ELECTRIC SYSTEM

1

2

3

4

5Expansion Thermostatic Valve

6

7

8

9

10

11

18

12

13

14

16

Solenoid Valve

15

17

Solenoid valve is applied to stop refrigerant flow through a

line. It is a closing valve controlled remotely and under

electric operation.

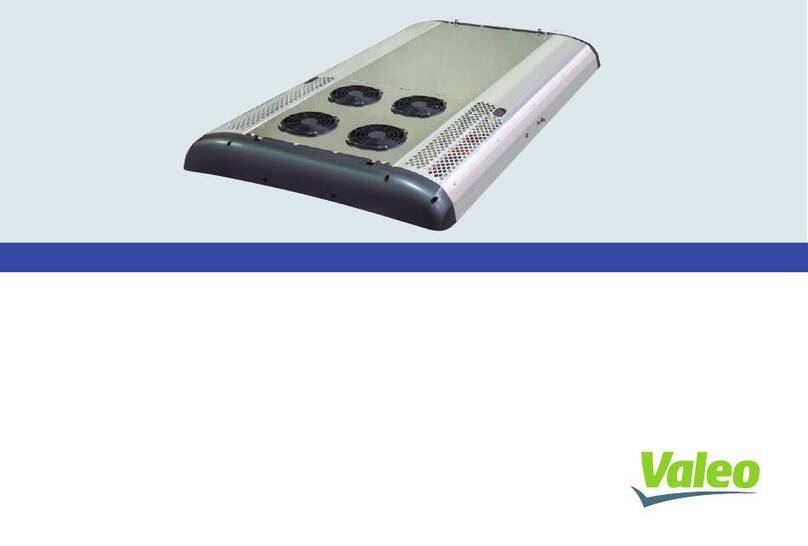

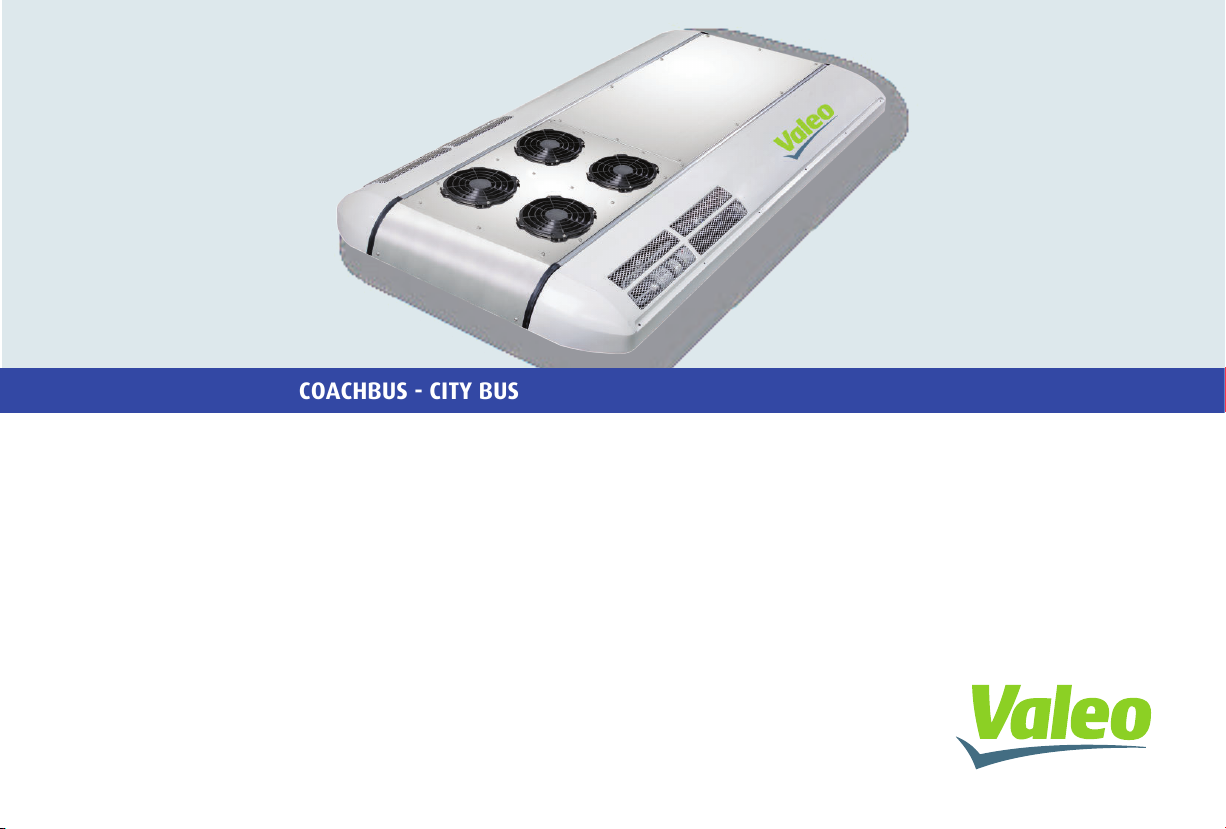

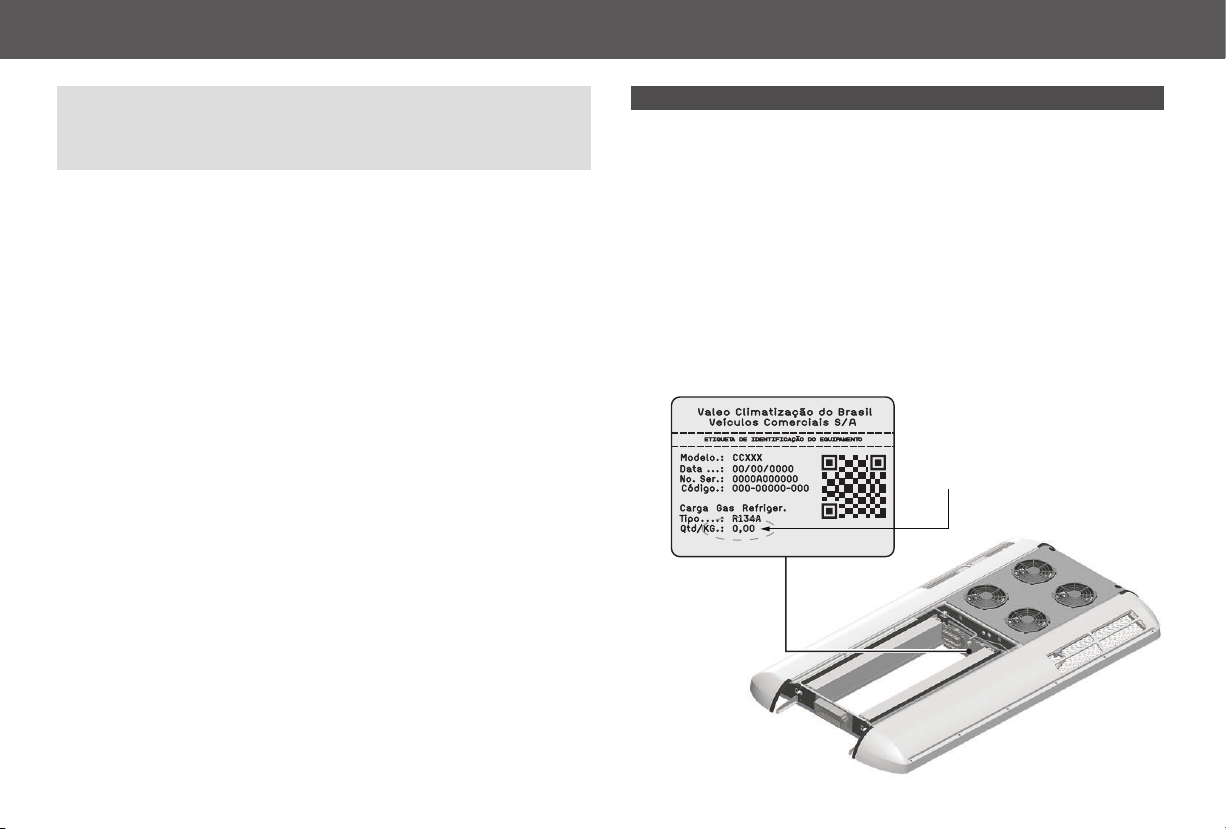

CC 305 - CC 335 - CC 355AIR CONDITIONING OPERATION

It is inside the air conditioning equipment, inside the

system. It works absorbing the heat from the interior

/ room of the vehicle, at the evaporator, and then it

goes to the condenser where the heat is thrown to

the outside. VALEO Climatização do Brasil - Veículos

Comerciais S/A, products apply refrigerant R134a,

according to the Protection Environmental Law.