Table of Contents

1 Introduction - Hyperion Optical Sensor ........................................................................................... 3

1.1 Fluorophore & Nomenclature .............................................................................................................. 3

1.2 PCB Update........................................................................................................................................... 3

1.3 Calibration Update ................................................................................................................................ 3

2 Sensors................................................................................................................................................ 4

2.1 Fluorometers ......................................................................................................................................... 4

2.1.1 Chlorophyll a ......................................................................................................................................................4

2.1.2 Fluorescein (Uranine).......................................................................................................................................4

2.1.3 Phycocyanin.......................................................................................................................................................5

2.1.4 Rhodamine WT ..................................................................................................................................................5

2.1.5 Sulforhodamine B .............................................................................................................................................5

2.1.6 Safety Statement...............................................................................................................................................6

2.2 Linear Observation Range.................................................................................................................... 6

2.3 Quenching ............................................................................................................................................. 7

2.4 Turbidity ................................................................................................................................................. 8

2.4.1 Turbidity Units....................................................................................................................................................8

2.4.2 Safety Statement...............................................................................................................................................8

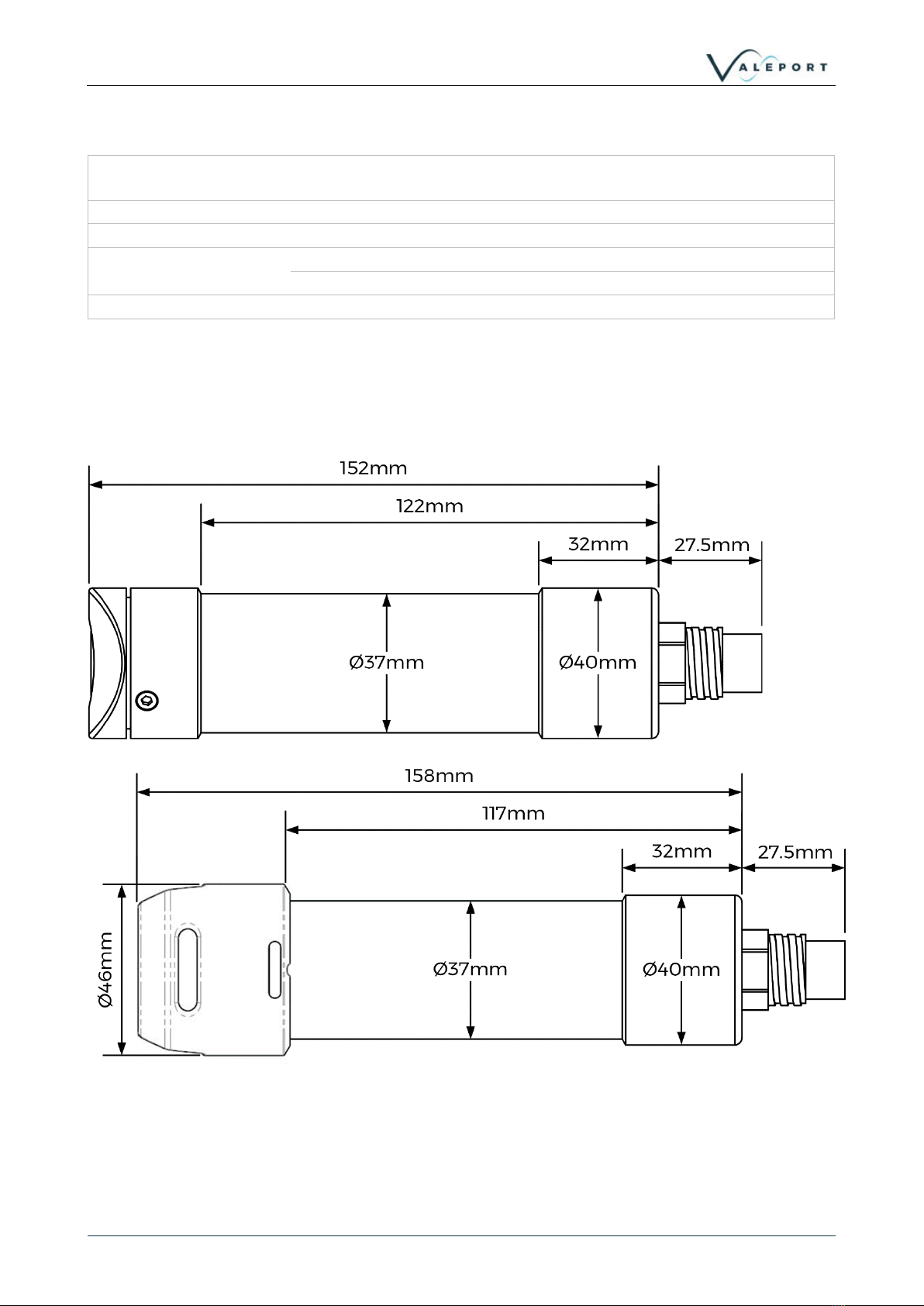

2.5 Physical Characteristics ....................................................................................................................... 9

2.5.1 Dimensions.........................................................................................................................................................9

3 Data Acquisition................................................................................................................................ 10

3.1 Output Rate.......................................................................................................................................... 10

3.2 Operating Modes ................................................................................................................................ 10

3.2.1 Mode C - Continuous .....................................................................................................................................11

3.2.2 Mode M - Continuous Measurement...........................................................................................................11

3.2.3 S Mode..............................................................................................................................................................11

4 Functional Check.............................................................................................................................. 12

4.1 User Calibration Factor and Offset .................................................................................................... 12

5 Operation with Multiple Dye Types ................................................................................................ 14

6 Operation with 400 Series Instruments ......................................................................................... 15

7 Communications............................................................................................................................... 16

7.1 Data Output Format $PVHYP (Pre November 2020)....................................................................... 16

7.2 Data Output Format $PVHY2 (Post November 2020) ..................................................................... 17

7.3 Hash (#) Codes ................................................................................................................................... 18

7.4 Modbus Operation .............................................................................................................................. 20

7.4.1 Modbus Register Lookup Table ...................................................................................................................22

8 Electrical ............................................................................................................................................ 25

8.1 Interface Cable –0901EA2 ................................................................................................................ 25

8.2 0400 Series Interface Cable............................................................................................................... 25

9 Care and Maintenance..................................................................................................................... 26

9.1 Fitting a Sensor Guard........................................................................................................................ 26

10 Software............................................................................................................................................. 27

10.1 Valeport Configure App...................................................................................................................... 27

10.1.1 Interface to the Hyperion...............................................................................................................................28

10.1.2 Configure the Instrument...............................................................................................................................30

10.1.3 Configure with Operation as Part of an EnviroLog System.....................................................................33

10.1.4 Sampling Scenario..........................................................................................................................................34

10.1.5 Calibration ........................................................................................................................................................35

11 Setting the Gain (Units with a Serial Number earlier than 75100).............................................. 36

12 Ordering and Part Numbers............................................................................................................ 38

12.1 Fluorometer ......................................................................................................................................... 38

12.2 Turbidity ............................................................................................................................................... 38

12.3 Accessories ......................................................................................................................................... 38

13 Declarations of Conformity.............................................................................................................. 39

13.1 UK Declaration of Conformity - UKCA Marking................................................................................ 39

13.2 EU Declaration of Conformity - CE Marking ..................................................................................... 40