Contents

1 Introduction ........................................................................................................................................... 1

2 Sensors................................................................................................................................................... 2

2.1 Pressure Sensor............................................................................................................................... 2

2.2 Interchangeable Pressure Sensor Modules..................................................................................... 2

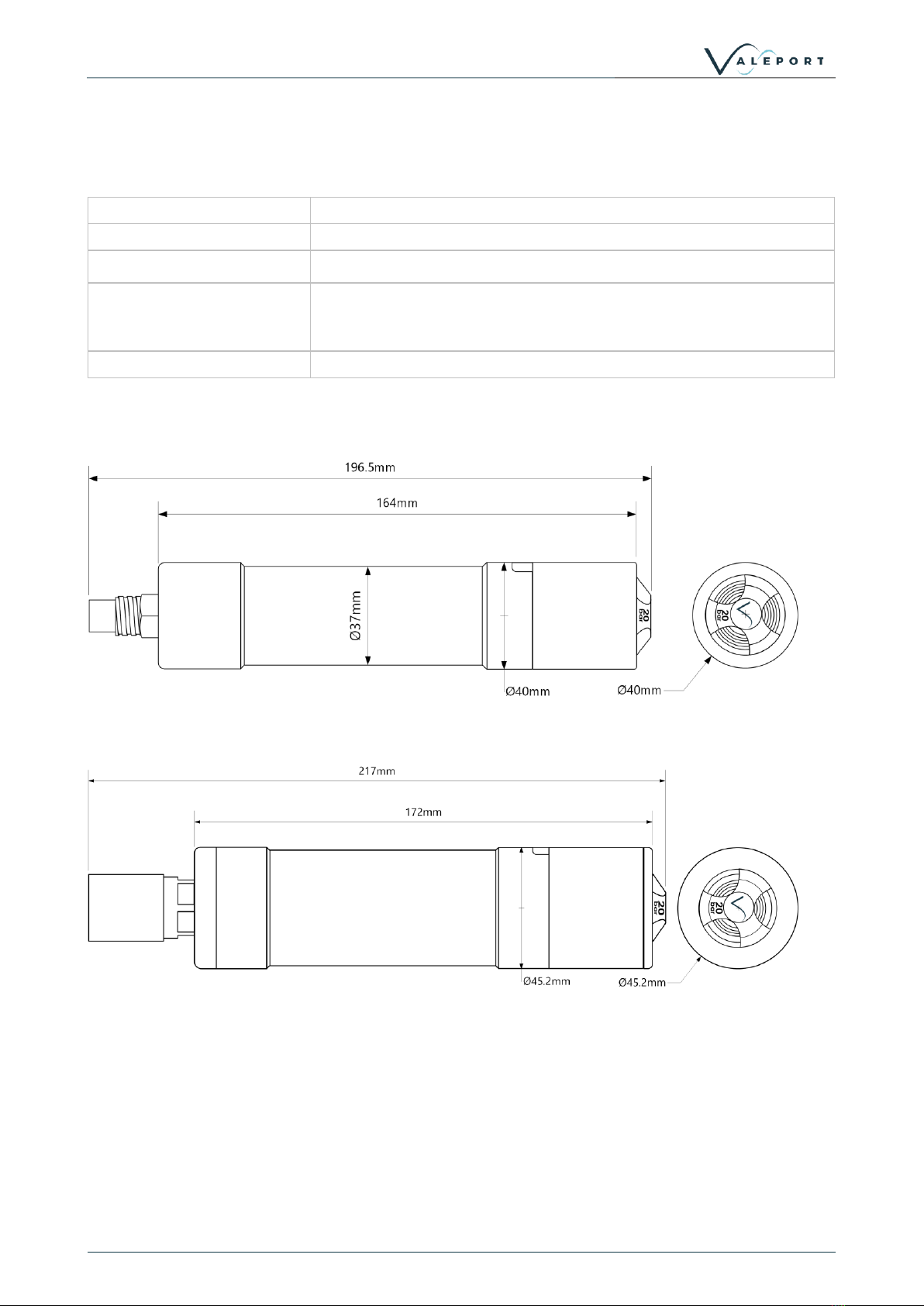

3 Physical Characteristics .......................................................................................................................... 4

3.1 Materials......................................................................................................................................... 4

3.2 Dimensions - miniIPS 2.................................................................................................................... 4

3.3 Dimensions - miniIPS 2e.................................................................................................................. 4

4 Communications .................................................................................................................................... 5

4.1 Introduction .................................................................................................................................... 5

4.2 Serial Comms - RS 232 and RS485................................................................................................... 5

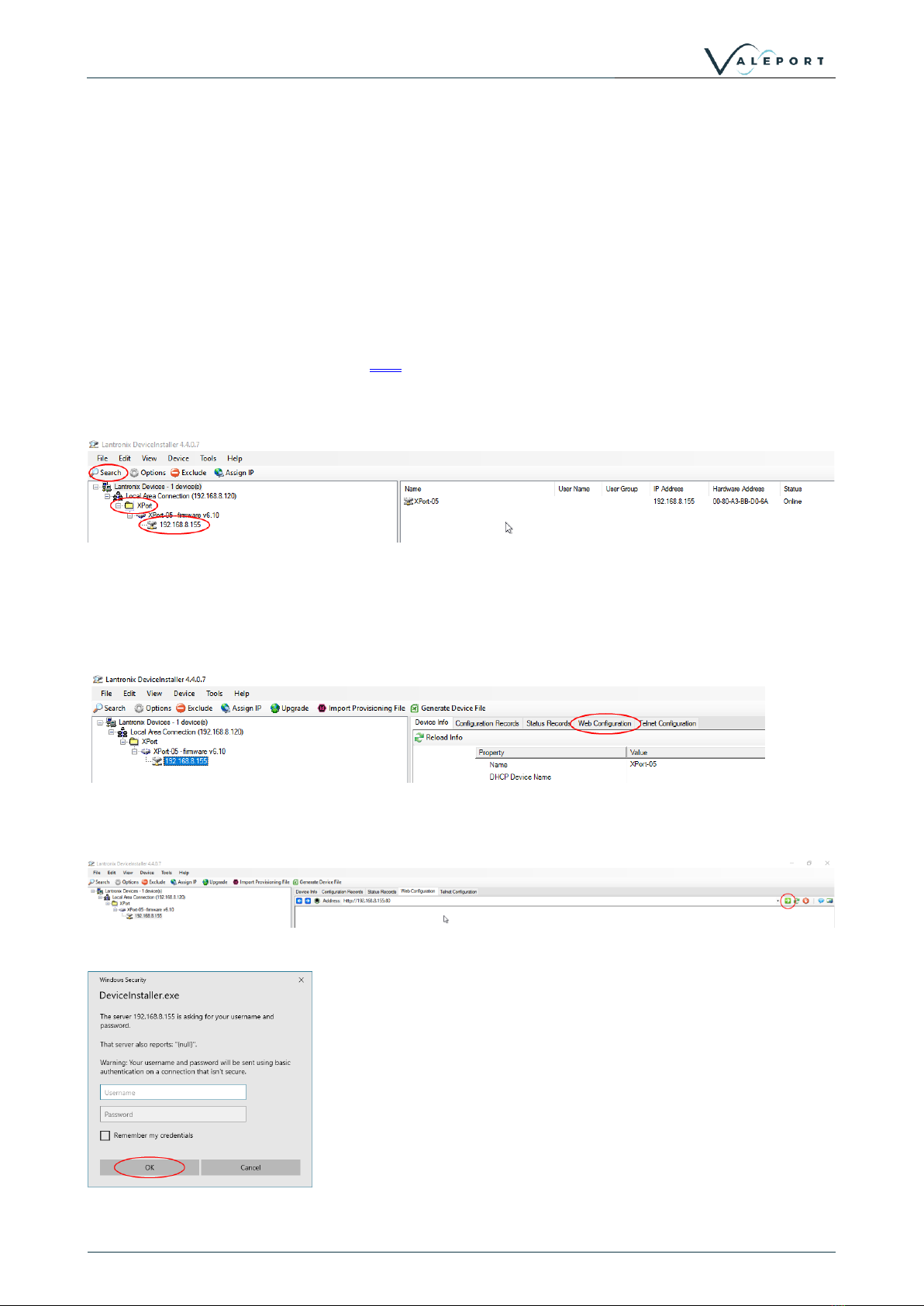

4.3 Ethernet .......................................................................................................................................... 6

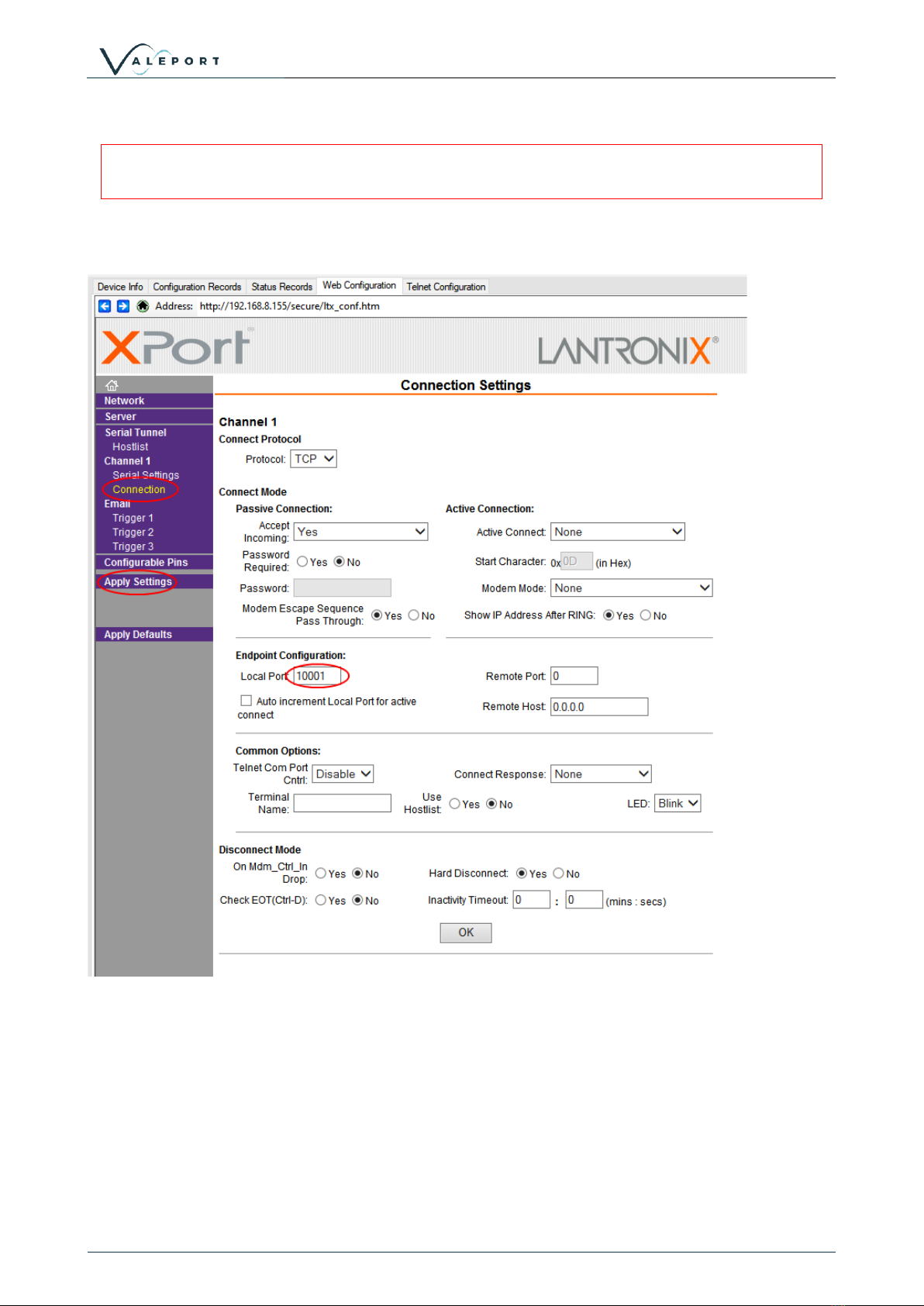

4.3.1 Setting up Ethernet Connectivity........................................................................................... 6

4.3.2 Operation with Datalog x2..................................................................................................... 9

4.3.3 Instrument Communications Setup ....................................................................................... 9

5 Setting Up the mniIPS2 ........................................................................................................................ 11

5.1 Start / Stop.................................................................................................................................... 11

5.1.1 Output Last Measured Reading ........................................................................................... 11

5.2 Welcome Message........................................................................................................................ 12

5.3 Warning Message ......................................................................................................................... 13

5.4 Error Flag....................................................................................................................................... 13

5.5 Sampling Modes............................................................................................................................ 14

5.6 Units.............................................................................................................................................. 15

5.6.1 Commands........................................................................................................................... 15

5.7 Pressure Tare ................................................................................................................................ 16

5.8 Set Latitude................................................................................................................................... 17

5.9 Standard Set Up ............................................................................................................................ 17

5.10 Information #Codes ...................................................................................................................... 18

6 Data Output Formats ........................................................................................................................... 19

6.1 Data String Formatting.................................................................................................................. 19

6.2 Format: Valeport CSV.................................................................................................................... 19

6.3 Format: Valeport (Standard) ......................................................................................................... 20

6.4 Format: Valeport NMEA ($PIPS).................................................................................................... 20

6.5 Format: Valeport NMEA ($PVIPS2) ............................................................................................... 21

6.6 Format: CSV .................................................................................................................................. 21

6.7 Format: Digiquartz ........................................................................................................................ 22

6.8 Format: Digiquartz CDL ................................................................................................................. 22

6.9 Format: Hypack............................................................................................................................. 22

6.10 Format: Impact SubSea................................................................................................................. 23

6.11 Modbus RTU over RS485............................................................................................................... 23