Contents

1 Introduction ........................................................................................................................................... 1

2 Sensors................................................................................................................................................... 2

2.1 Sound Velocity Measurement......................................................................................................... 2

2.2 Temperature ................................................................................................................................... 2

2.3 Pressure .......................................................................................................................................... 2

2.3.1 Interchangeable Pressure Sensor Modules............................................................................ 3

2.4 Calculated Parameters.................................................................................................................... 5

2.4.1 Calculated Conductivity ......................................................................................................... 5

2.4.2 Calculated Salinity.................................................................................................................. 5

2.4.3 Calculated Density ................................................................................................................. 5

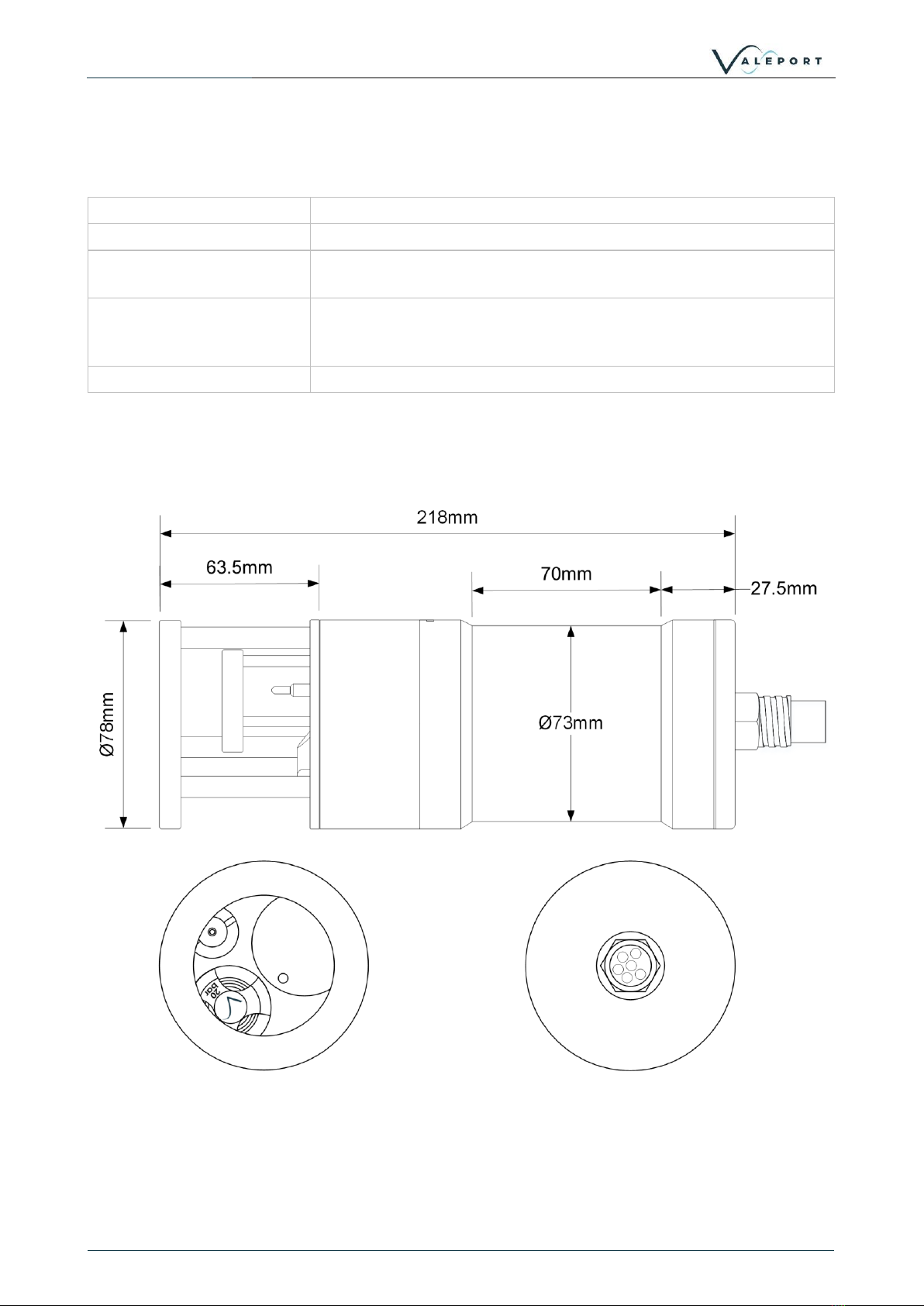

3 Physical Characteristics .......................................................................................................................... 6

3.1 Materials......................................................................................................................................... 6

3.2 Dimensions ..................................................................................................................................... 6

4 Communications .................................................................................................................................... 7

4.1 Serial Comms - RS 232 and RS485................................................................................................... 7

4.2 Ethernet .......................................................................................................................................... 8

4.2.1 Setting up Ethernet Connectivity........................................................................................... 8

4.2.2 Operation with Datalog x2................................................................................................... 11

4.3 uvSVX Communications Setup ...................................................................................................... 12

5 Setting Up the uvSVX ........................................................................................................................... 13

5.1 Start / Stop.................................................................................................................................... 13

5.1.1 Output Last Measured Reading ........................................................................................... 13

5.2 Information #Codes ...................................................................................................................... 14

5.3 Sampling Modes............................................................................................................................ 15

5.4 Pressure Tare ................................................................................................................................ 15

5.5 Error Flag....................................................................................................................................... 16

5.6 Warning Message ......................................................................................................................... 16

5.7 Pressure | Depth Units.................................................................................................................. 17

5.8 Set Latitude................................................................................................................................... 17

5.9 DASH Formula............................................................................................................................... 18

5.10 User Calibration ............................................................................................................................ 18

6 Data Output Formats ........................................................................................................................... 19

6.1 Data String Formatting.................................................................................................................. 19

6.2 CSV Format ................................................................................................................................... 20

6.3 Valeport NMEA ($PVSVX).............................................................................................................. 21

6.4 Data String #1................................................................................................................................ 22

6.5 Modbus RTU ................................................................................................................................. 22

7 Electrical............................................................................................................................................... 23

7.1 Power uvSVX................................................................................................................................. 23

7.2 Power uvSVXe ............................................................................................................................... 23

7.3 Wiring Information ....................................................................................................................... 23