Table of Contents

1Introduction - Hyperion Optical Sensor.....................................................................3

1.1 Fluorophore & Nomenclature..........................................................................................3

1.2 PCB Update ....................................................................................................................3

2Sensors....................................................................................................................4

2.1 Fluorometers...................................................................................................................4

2.1.1 Chlorophyll a................................................................................................................. 4

2.1.2 Fluorescein (Uranine)................................................................................................... 4

2.1.3 Phycocyanin................................................................................................................. 5

2.1.4 Rhodamine WT............................................................................................................. 5

2.1.5 Sulforhodamine B......................................................................................................... 5

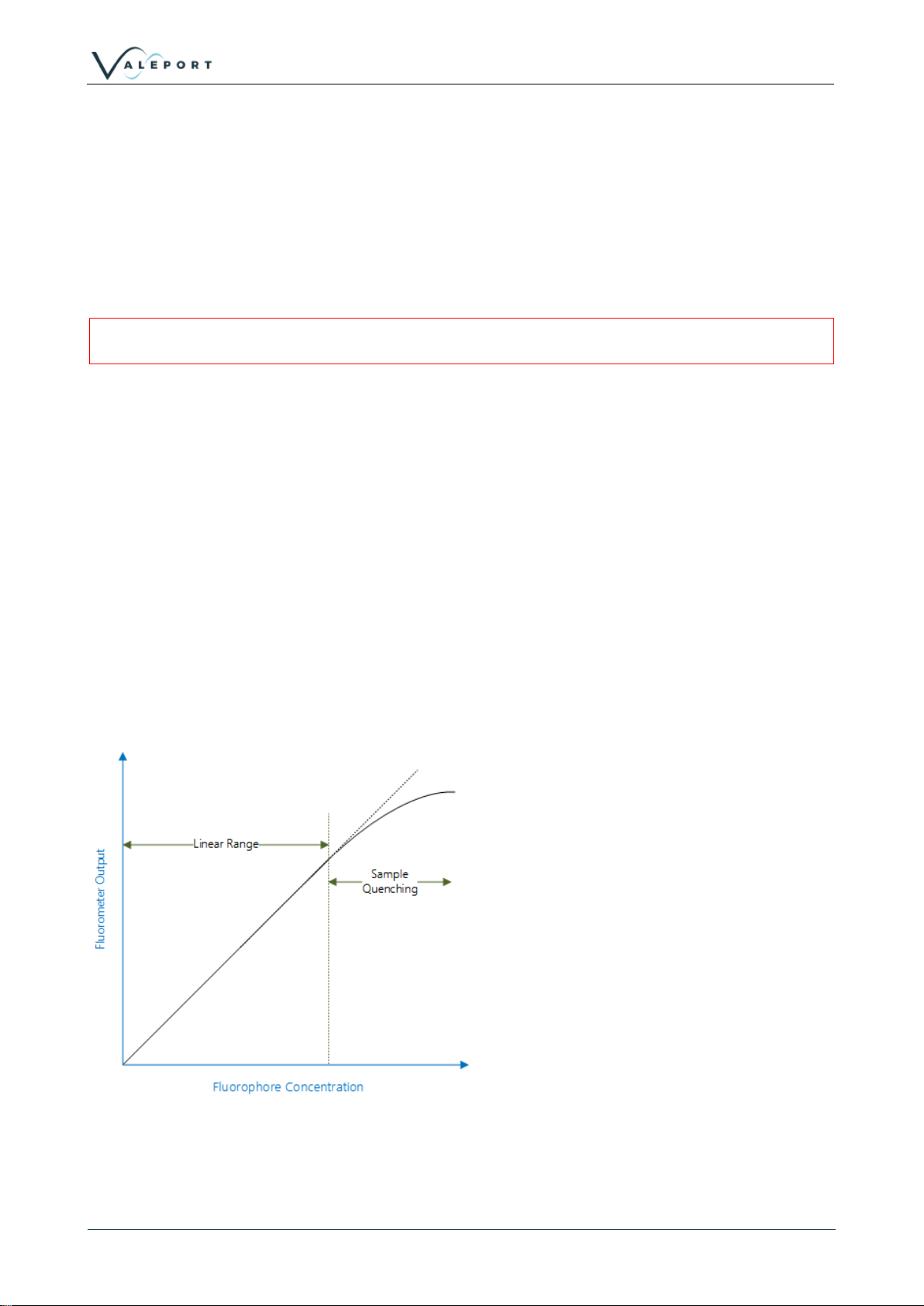

2.2 Linear Observation Range..............................................................................................6

2.3 Quenching.......................................................................................................................7

2.4 Turbidity...........................................................................................................................8

2.4.1 Turbidity Units............................................................................................................... 8

2.4.2 Safety Statement.......................................................................................................... 8

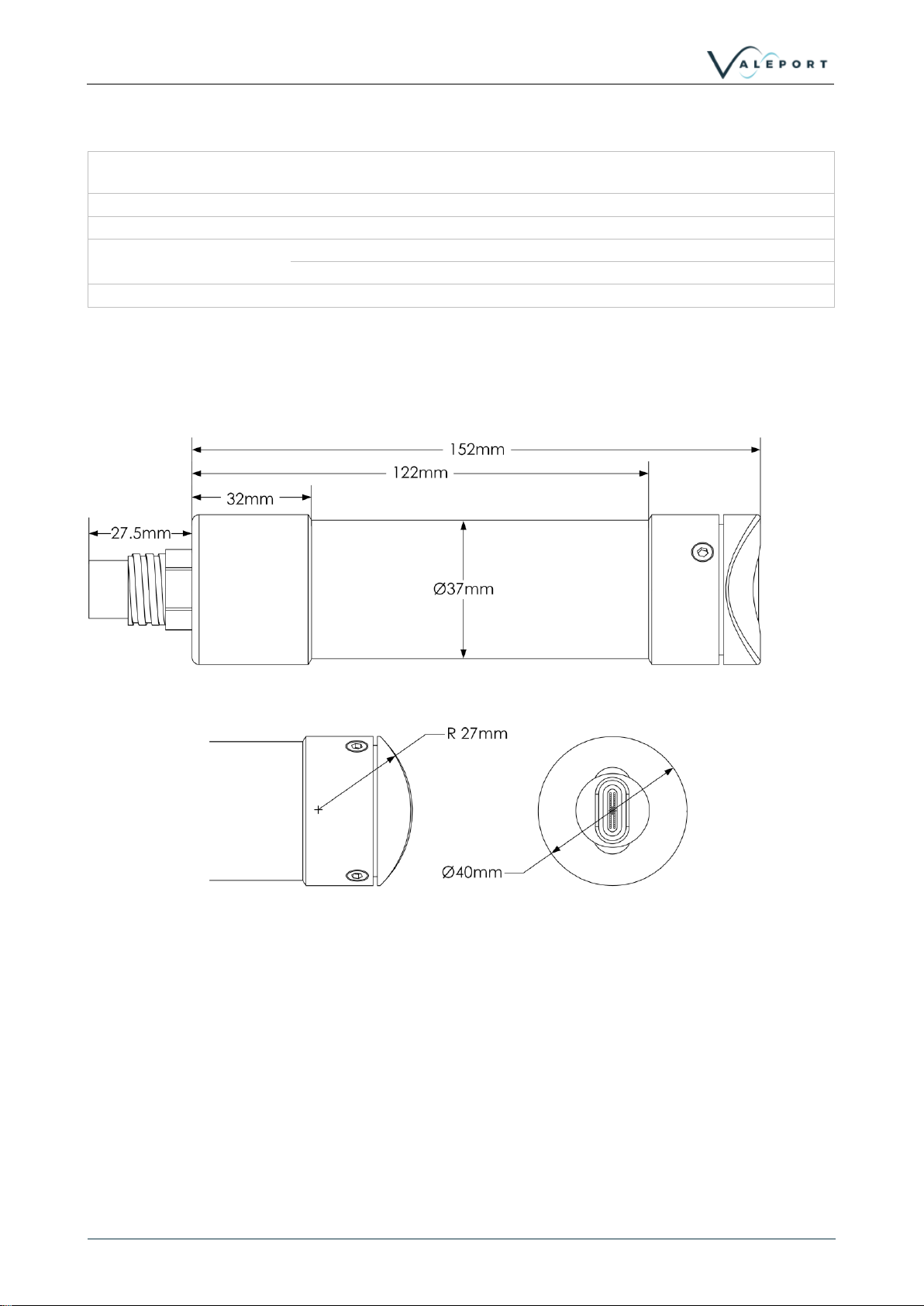

2.5 Physical Characteristics..................................................................................................9

2.5.1 Dimensions................................................................................................................... 9

3Data Acquisition.....................................................................................................10

3.1 Setting the Gain.............................................................................................................10

3.1.1 Turbidity...................................................................................................................... 12

3.2 Output Rate...................................................................................................................12

3.3 Functional Check ..........................................................................................................12

4Operation with 400 Series Instruments...................................................................17

5Electrical ................................................................................................................18

5.1 Connector Pin-Out ........................................................................................................18

5.2 0400 Series Interface Cable .........................................................................................18

6Communications ....................................................................................................19

6.1 Data Output Format $PVHYP (Pre November 2020)...................................................19

6.2 Data Output Format $PVHY2 (Post November 2020) .................................................20

6.3 Operating Modes...........................................................................................................21

6.3.1 Mode C - Continuous.................................................................................................. 21

6.3.2 Mode M - Continuous Measurement .......................................................................... 21

6.4 Hash (#) Codes.............................................................................................................22

7Care and Maintenance...........................................................................................23

8Software.................................................................................................................24

8.1 DataLog x2....................................................................................................................24

8.2 Valeport Configure App.................................................................................................24

8.2.1 Interface to the Hyperion............................................................................................ 25

8.2.2 Configure the Instrument............................................................................................ 26

8.2.3 Configure with Operation as Part of an EnviroLog System......................................... 27

9Ordering and Part Numbers...................................................................................29

9.1 Fluorometer...................................................................................................................29

9.2 Turbidity.........................................................................................................................29

9.3 Accessories...................................................................................................................29

10 Declarations of Conformity.....................................................................................30

10.1 KU Declaration of Conformity - UKCA Marking............................................................30

10.2 EU Declaration of Conformity - CE Marking.................................................................31