4

USING THE UNIT

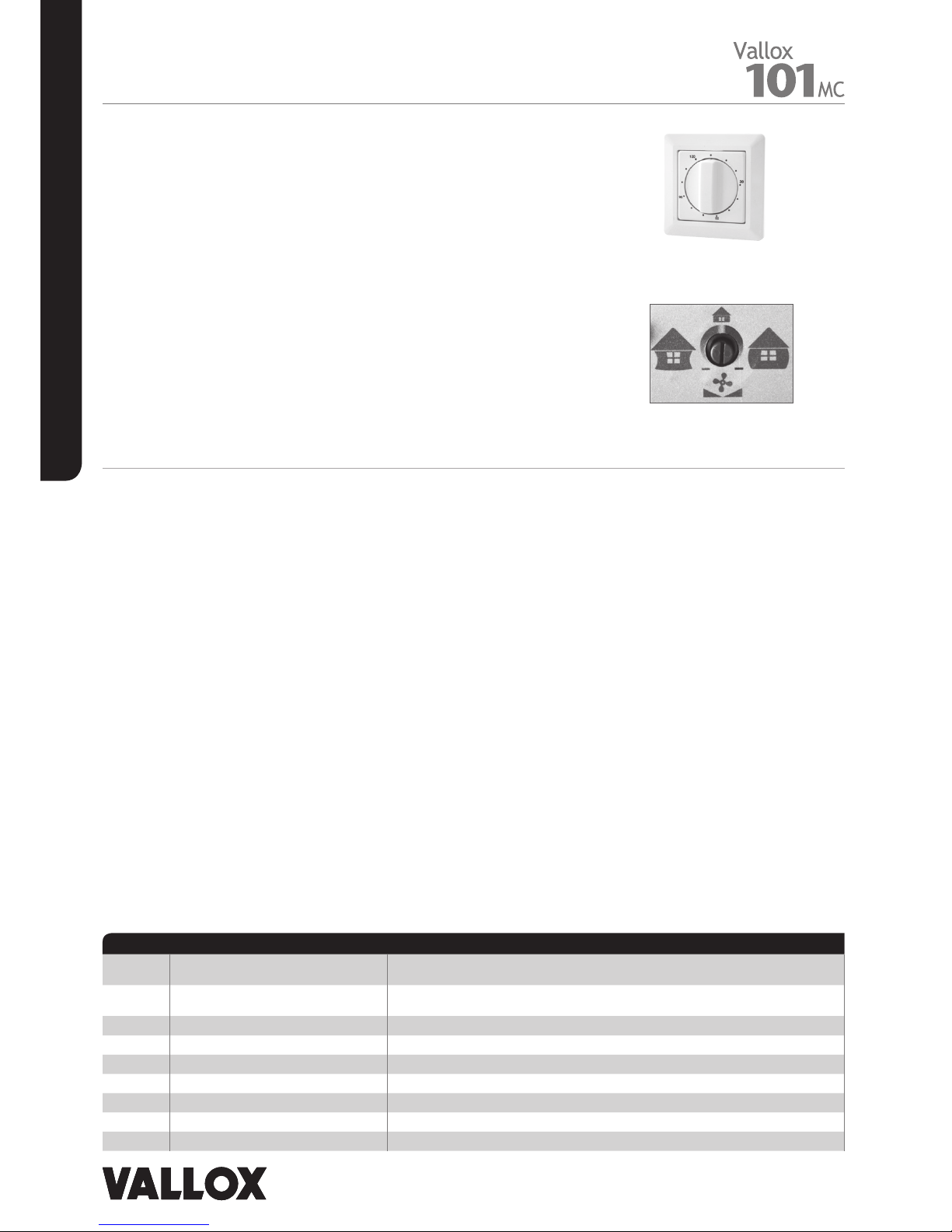

FIREPLACE SWITCH

A switch with timer functions can be connected to the unit. The switch stops the

extract air fan when the fireplace is being used. NOTE! Starting up the extract

air fan can reduce the draw of the fireplace! In winter, this can disturb the winter

mode of the ventilation unit. The situation will return to normal soon after the

fireplace mode is turned o.

ADJUSTING THE SUPPLY AND EXTRACT AIR

RATIO

This function might be needed when the air flows are adjusted at the valves

during installation. The user does not need to adjust this function once

the valves have been adjusted, and indeed should not adjust it at all. A

potentiometer can be used to reduce the supply or extract air flow as required.

When the potentiometer is set roughly in the centre position, neither the supply

nor the extract air flow has been reduced. When the potentiometer is turned

anti-clockwise, the supply air flow is reduced, and when the potentiometer is

turned clockwise, the extract air flow is reduced.

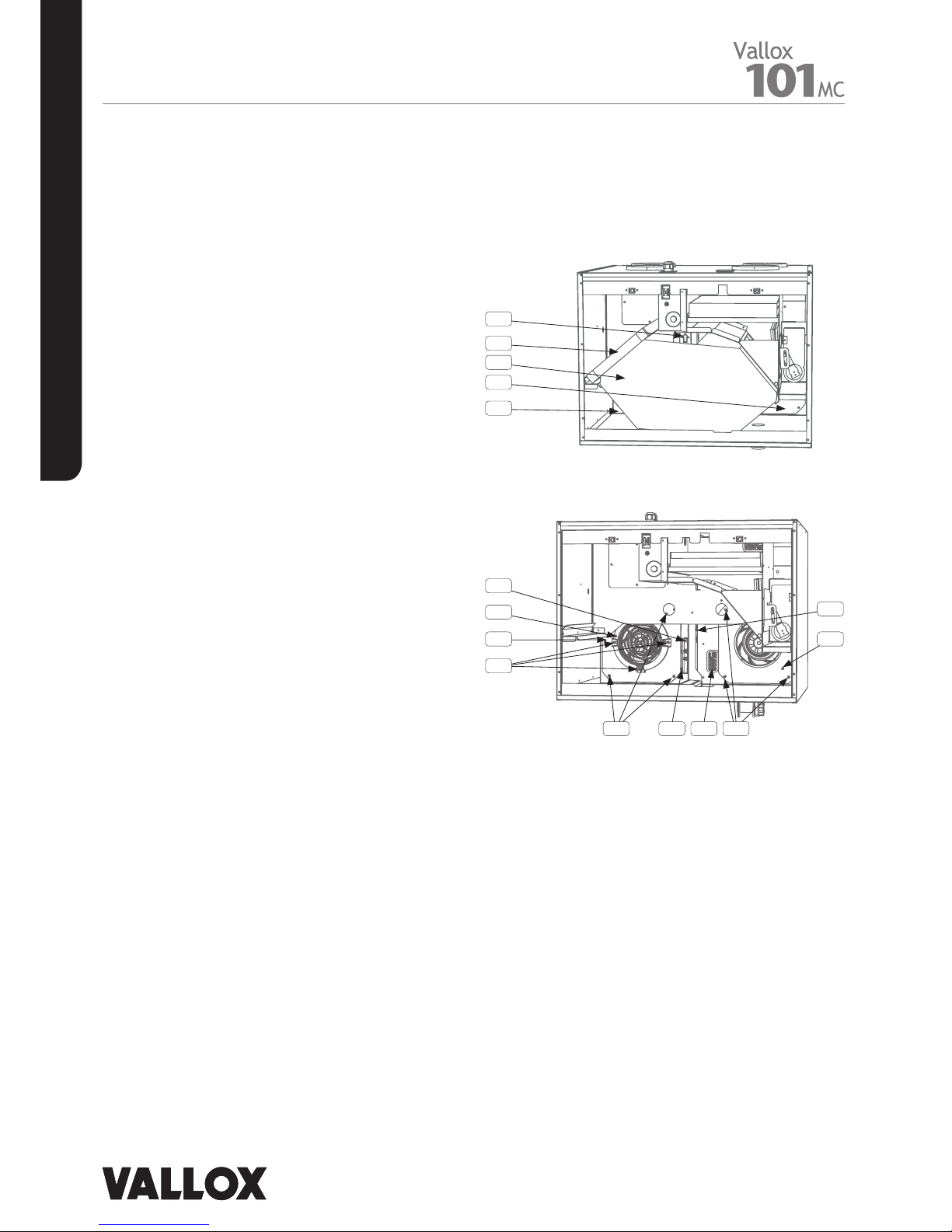

The potentiometer for adjusting

the supply and extract air flows

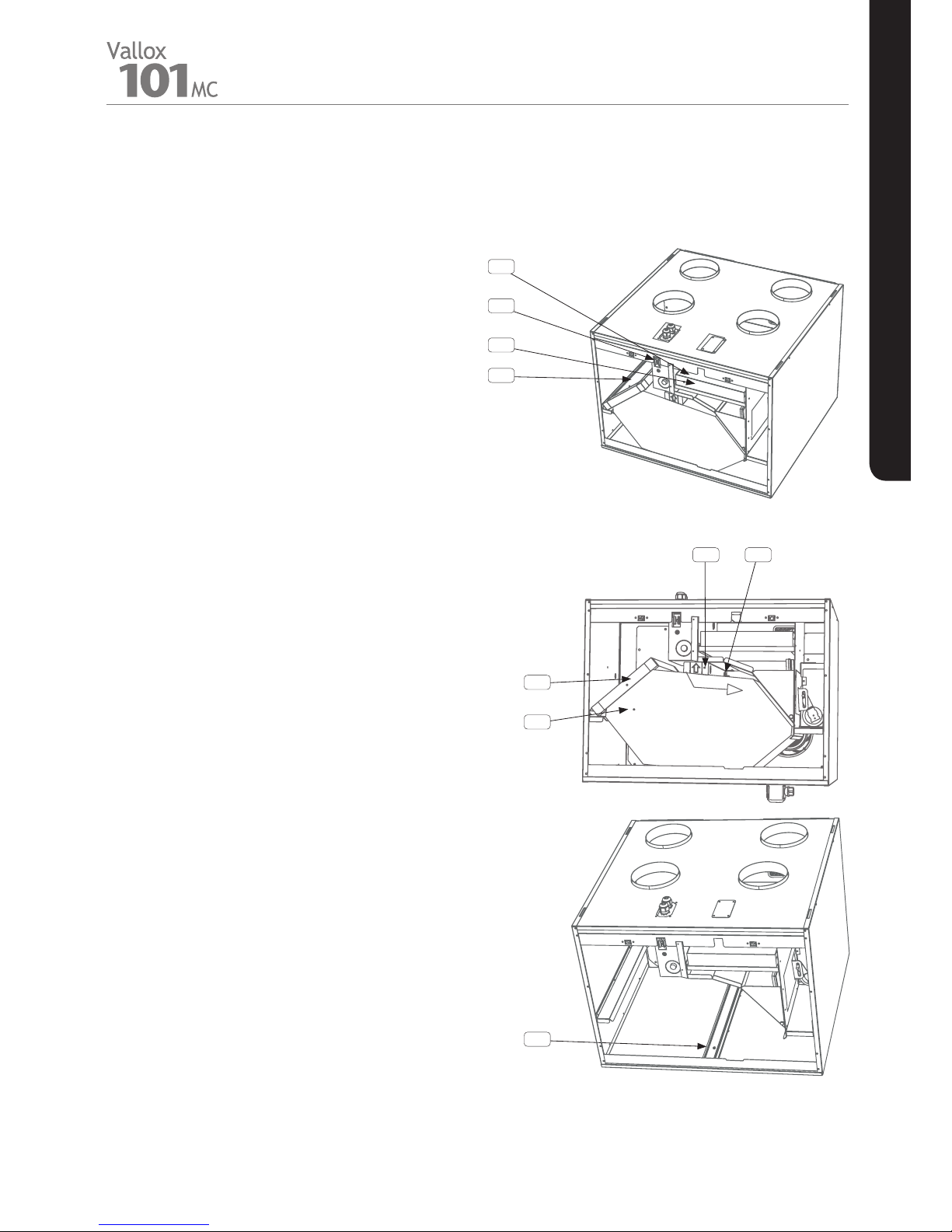

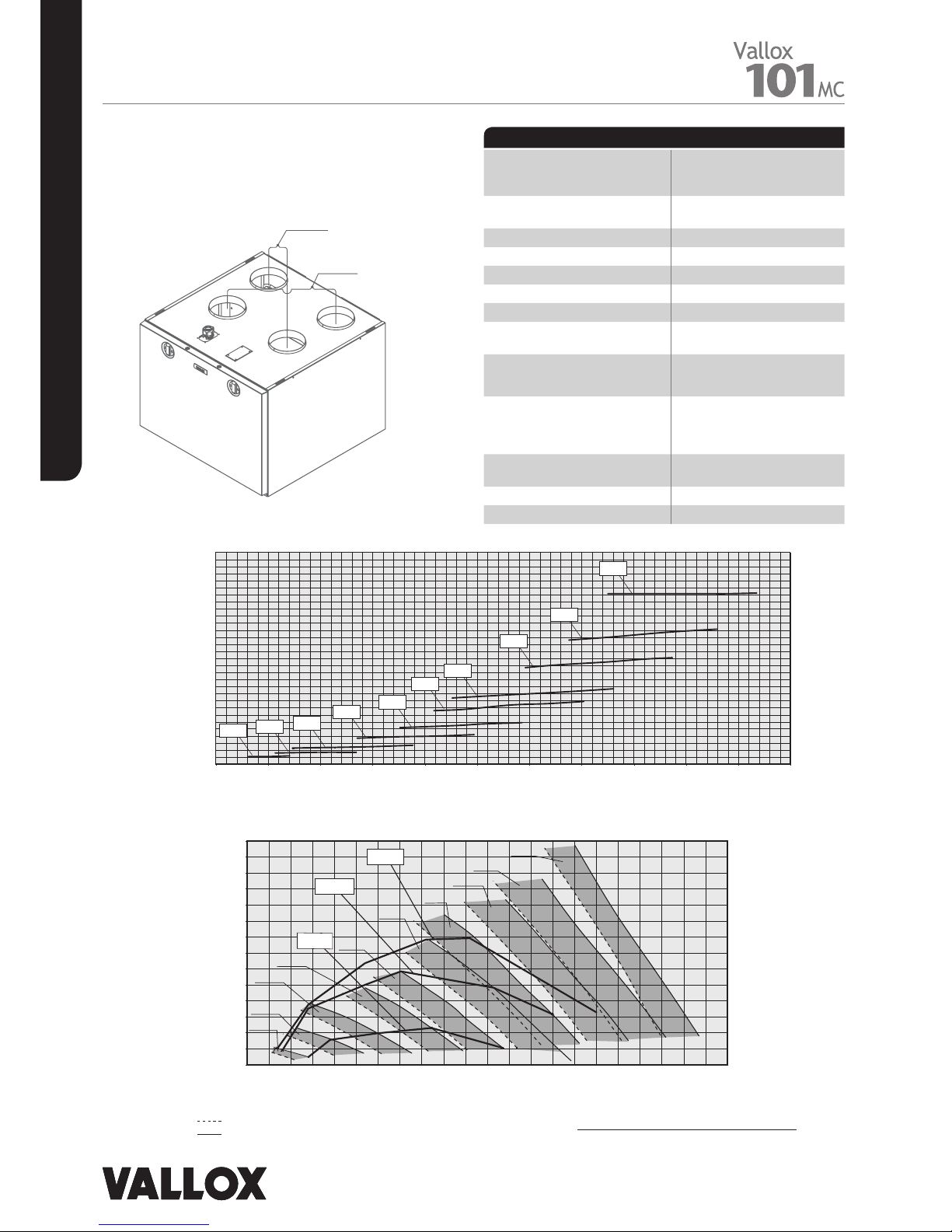

TROUBLESHOOTING

Flashing

LED

Problem Correction

1 NTC sensor of the supply air from the cell

is faulty

Check the sensor and the wires, replace as required

2 NTC sensor of the extract air is faulty Check the sensor and the wires, replace as required

3 NTC sensor of the extract air is faulty Check the sensor and the wires, replace as required

4 NTC sensor of the exhaust air is faulty Check the sensor and the wires, replace as required

5 NTC sensor of the outdoor air is faulty Check the sensor and the wires, replace as required

6 The supply air fan has stopped. Check the wiring of the fan, re¸place the fan as required

7 The extract air fan has stopped. Check the wiring of the fan, replace the fan as required

8 EEPROM is faulty Replace the circuit board

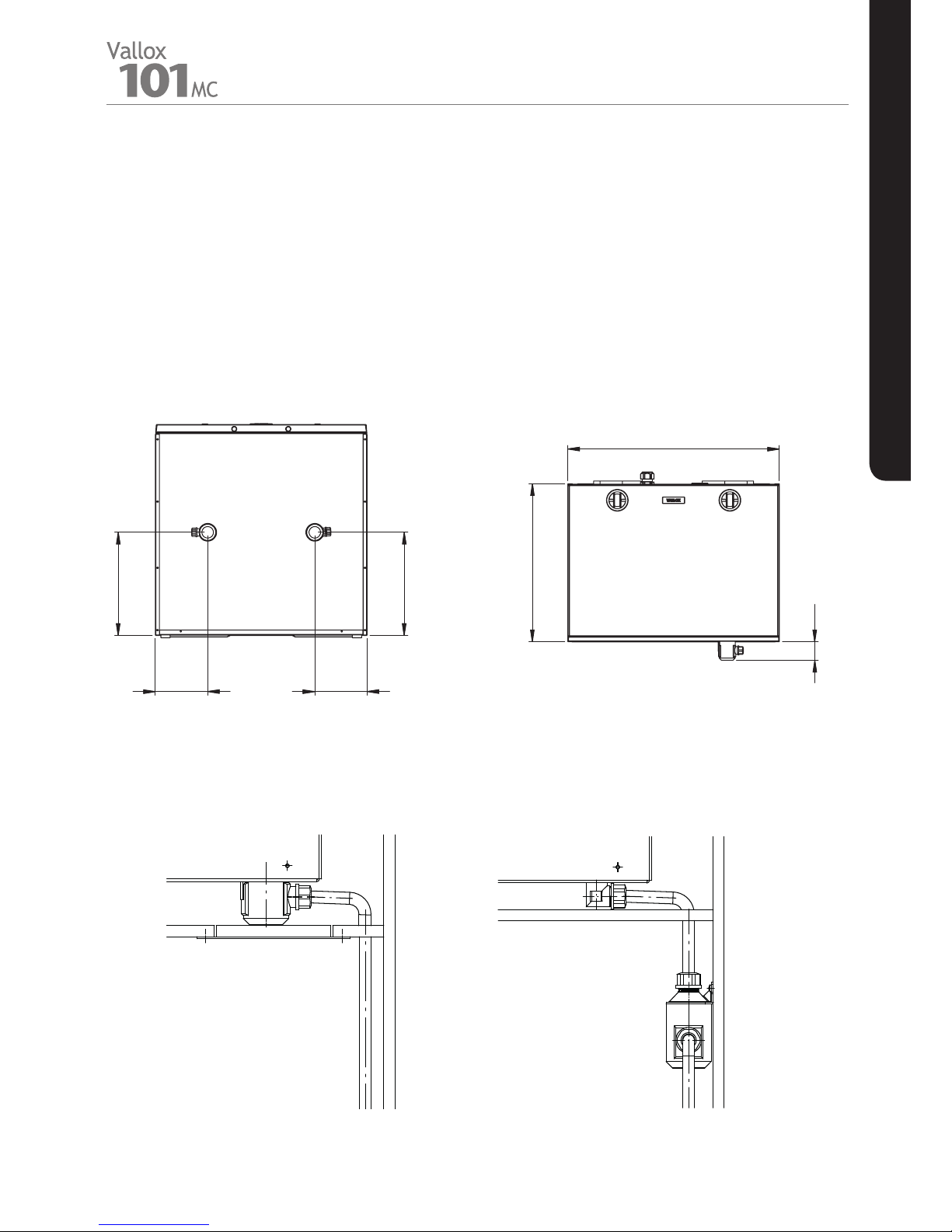

Concealed installation of

the fireplace switch (optional)

TROUBLESHOOTING TABLE

If the ventilation unit is aected by any of the errors listed in the table, the unit will report the error through the error relay,

signal light, and circuit board LEDS. The number of flashes indicates the nature of the error.

The error relay can be connected to remote monitoring.

NOTE! When remote monitoring is used, the signal light of the control panel cannot be turned on.

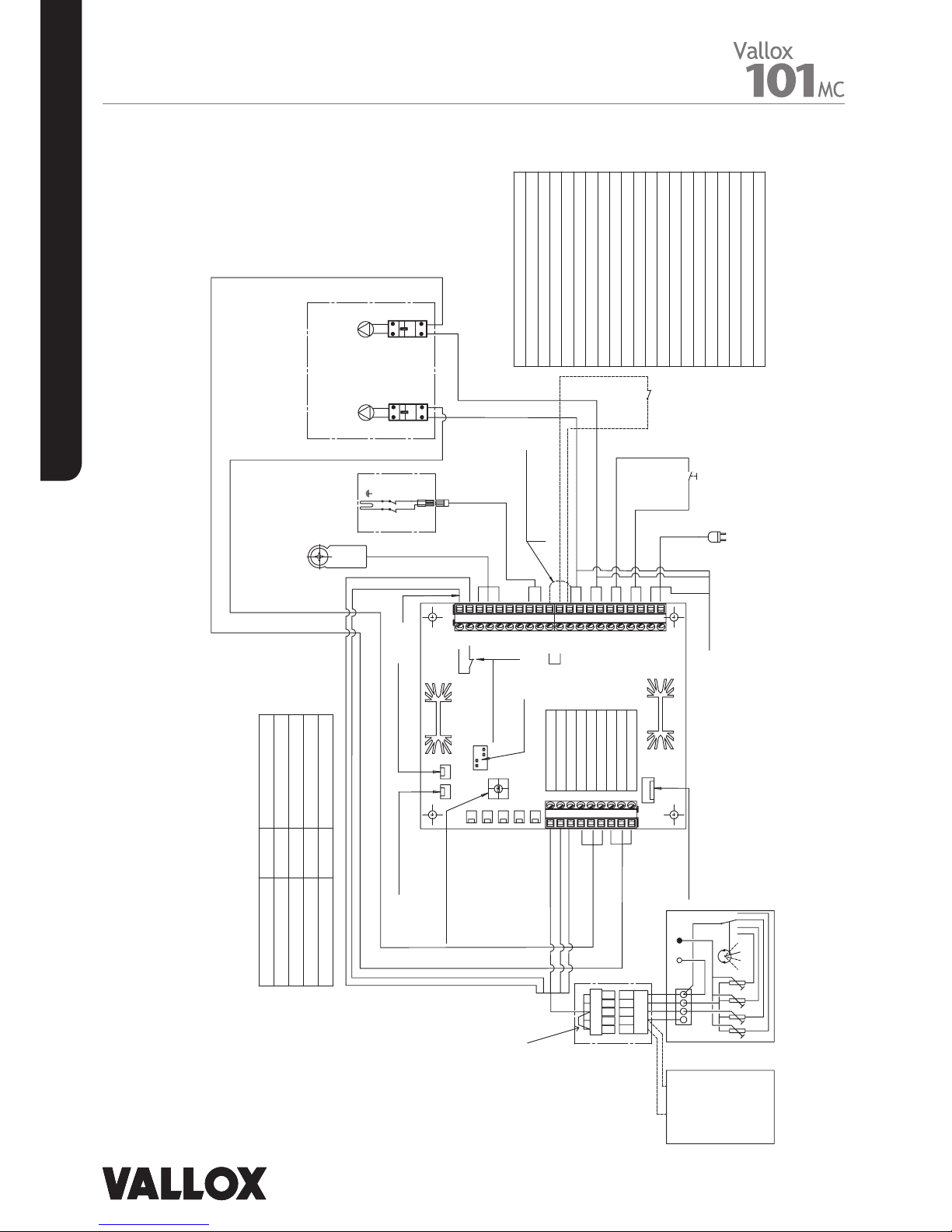

MAINTENANCE REMINDER

If a signal light is connected to the connectors of the unit’s error relay, the unit will send a reminder of service need every

six months,. If connected, the signal light will flash every second. Sounds made by the relay can then be heard from

inside the unit. The maintenance reminder will be set o automatically when the door of the ventilation unit is opened or

the power is turned o. The maintenance reminder can also be set o manually.

The Vallox Simple Control control panel, and the

Vallox X-Line PTXP MC and PTXPA MC control

hoods, VAK 0-10 VDC:

• The low speed is turned on, then higher-lower-higher

- Low speed under 4 V

- High speed over 6 V

- The selected speed will always be turned

on for 1-5 seconds

Vallox Capto PTC EC control hood:

• The damper is closed, then open-closed-open

• Press at a 1-5 second interval.

The service reminder will only be set o if it has been activated. Refer to the maintenance instructions for the necessary

maintenance measures.