INSTALLATION MANUAL ES 470

Shock and vibration detector

DESCRIPTION

ES 470 offers reliable monitoring against attacks with

mechanical tools. The ES 470 is a shock and vibration

detector with 3 separate detection channels: an integra-

tion channel / saw channel for weak signals with long

duration, a counting channel that senses strong impact

on the monitored surface and an explosion channel

which senses very strong signals from e.g. an explosion.

ES 470 has built-in relays for the alarm and tamper

outputs. This allows the ES 470 to be connected directly

to the alarm central unit, this means that no analyzer unit

is necessary.

The ES 470 is polarity independent.

FEATURES

•

Relay outputs for alarm and tamper

•

Polarity independent for easy connection

•

3 separate detection channels

•

Cover radius up to 3m

•

Resistant to interference

•

Detailed sensitivity setting

•

Suitable for 24-hour monitoring

•

DAY and NIGHT control of LED

OPERATING PRINCIPLE

The ES 470 uses a piezoelectric sensor to monitor the vibration

signature of the mounting surface that occurs when it is

crushed or cut with tools. The signal has a special signature

with a broad spectrum and high amplitude that the electronics

detects, then opens the alarm relay and illuminates the

LED. The ES 470 has a built-in self-control and voltage

monitoring. Fault is indicated by a flashing LED (alarm relay

remains closed). The indication is controlled by a DAY and

NIGHT function. With 8Vdc on the power input, DAY mode is

active and LED lights up at alarm and with pulsating shine in

case of failure. At 6Vdc, NIGHT mode is active and LED is

switched off in case of alarm or fault.

Resetting the detector after alarm can be done in two different

ways:

•Disconnect power to the detector

•Switch from DAY to NIGHT mode

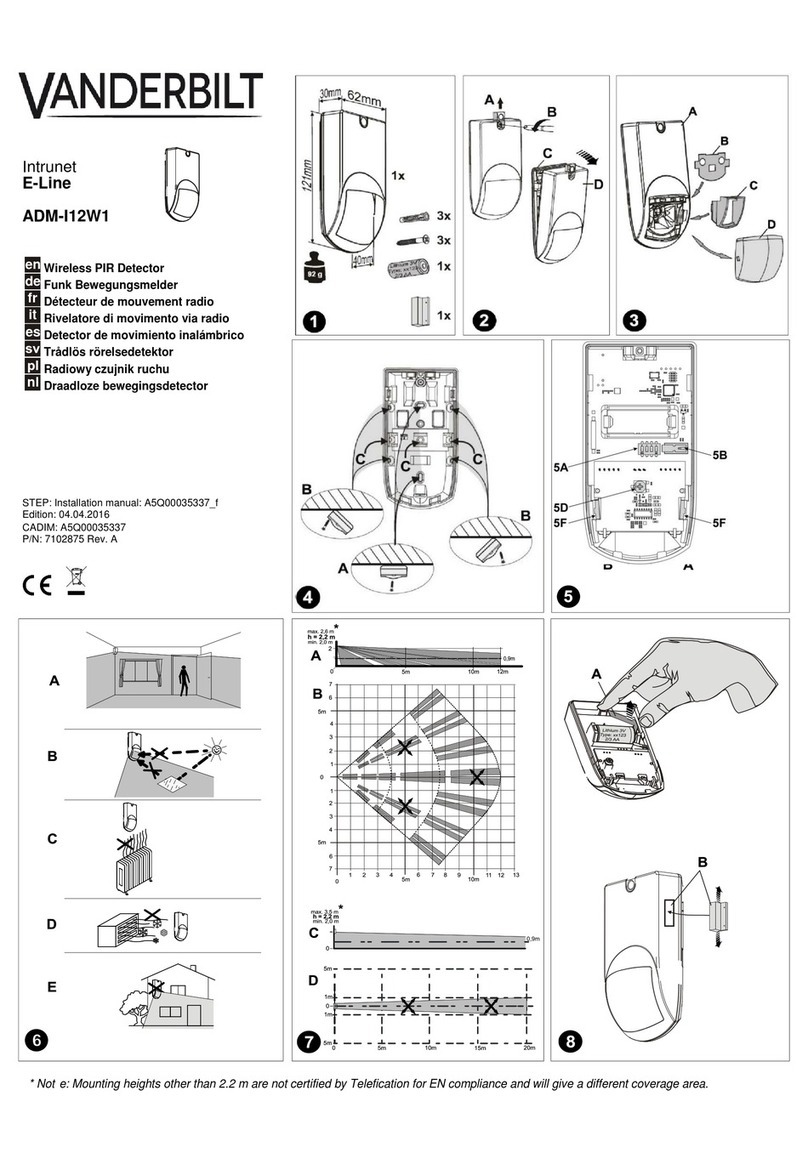

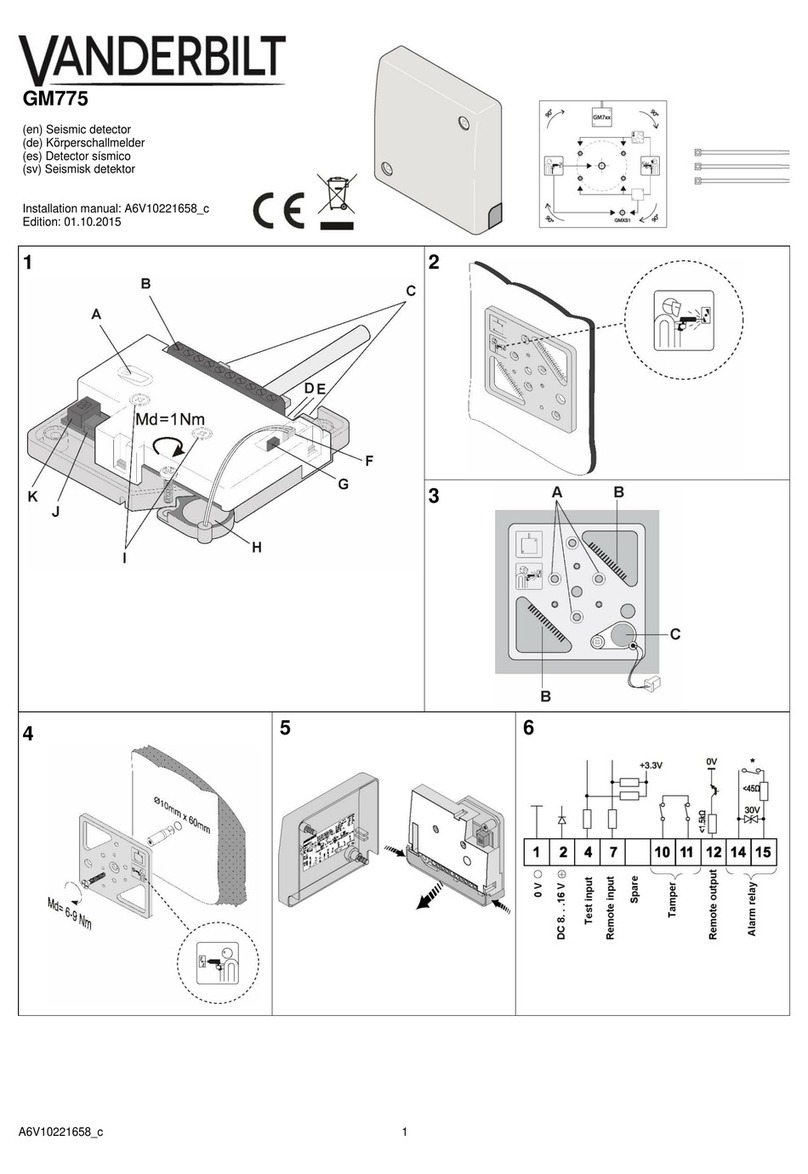

MOUNTING

1. Loosen the screw for the cover and lift it off.

2. Select the mounting location and mark the mounting holes

with the bottom part as a template.

3. Drill with a 2-2.5 mm drill for the two supplied mounting

screws.

NOTE! A clean and smooth mounting surface under the

detector provides maximum range.

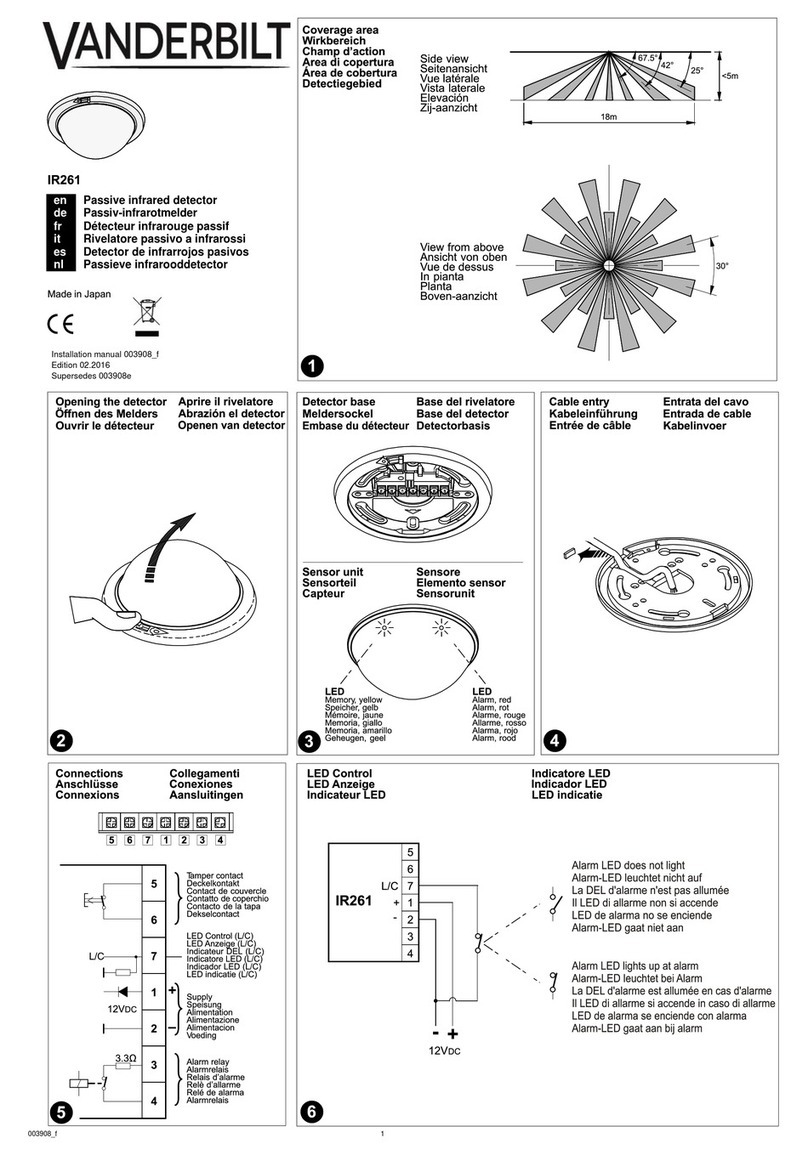

CONNECTIONS

The detector has 6 screw terminals:

ES470 manual I-200422 Page 1 of 2

DC Input voltage (-) or (+)

DC Input voltage (-) or (+)

Tamper output, relay (NC)