Vapor Rino 145 Owner's Manual Page 10 of 12

Important Care & Maintenance

Low Maintenance: Your Vapor Rino is made using quality materials and as such requires relatively little maintenance, however proper

maintenance and use is critical for reducing the potential for machine down time and service.

All machines, no matter the type eventually require maintenance, service and repair. For this reason it is advisable to keep your original box

and packing material. In the event that your system ever needs repair this will make sending it in to the nearest service center much easier.

Repair and maintenance are both a normal part of using any vapor system (or any other machine) on a regular, professional bases. Remember,

repair is not disaster but rather simple repair is part of any successful working business cycle. Any professional that depends upon one

machine for his or her whole living should have a backup plan. As your business expands and becomes more successful you may want to

consider purchasing a second smaller unit as a back up or to boost production.

✓Use Clean Pure Water: Use only Clean water for your boiler refill tank. Using clean filtered water greatly extends the life and performance of

your machine. You may also use clean tap water for your injection system. Cleaning your boiler is very easy, see cleaning section.

✓Do No Freeze: Never leave your machine out in freezing weather even if stored in your vehicle. If the internal components freeze you can

expect the water filled tubes inside may burst. This may cause serious damage to the machine. NEVER ALLOW TO FREEZE!

✓Store Indoors: Store your machine indoors in a dry room temperature place. Do not store your machine outdoors or in a high humidity

location. It is not recommended to store in a work vehicle as high temperatures & radical changes in temperature may have negative effects.

✓Keep Clean: A clean machine is a happy machine! Take pride in your new Vapor Rino and keep it clean. Wipe down often and clean accessories

after each use. This reduces the likely hood of damage due to foreign matter getting into switches and other components. It also makes your

company look good! Keep it clean, keep it professional!

✓Turn Off: Always turn your machine OFF when not in use for any extended period. Automotive Detailers and other users often turn on their

machine and leave it running upwards of 6 to 10 hours a day without giving it a rest. This is not recommeneded. This is unique to vapor

systems as they make very little sound, thus giving the appearance of not taking any wear. The fact is our high powered Vapor Rino produces

internal temperatures upwards of 356 Degrees Fahrenheit. This intense heat may some cause wear. For this reason it is advisable to press the

OFF button on your steamer if you are not going to use your steamer for more then 20 to 40 minutes. This reduces wear time and may

reduce the frequency of service and repair. Remember, once fully heated the Vapor Rino recovers very fast once turned back on. Contrast

this 6 to 10 hours of non stop usage with your other power tools. Most users would never consider running a shop vacuum, an extractor

motor or other power tool for 8 hours a day no stop for months on end and not expect to require service at some point. Simply turn your

vapor system off when not in use.

✓Drain Boiler: Always empty your boiler if you do not intend on using your machine for more then a 7 to 14 days. Long term storage of your

steamer with water in it may cause a swamp water like effect in your system. This may lead to sensor failure. If your going to pack it away for

the season, empty the boiler before you do

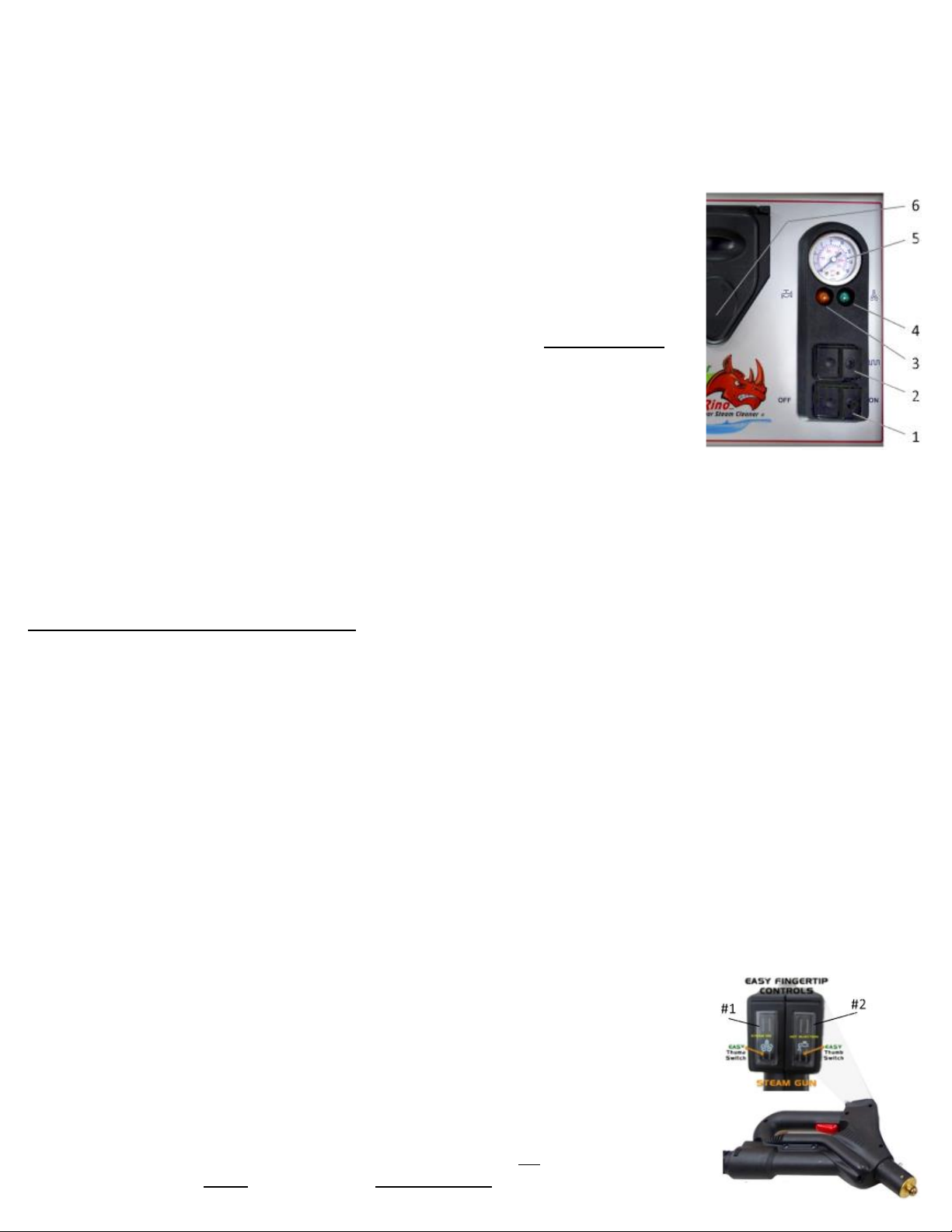

✓How To Drain Boiler: Simply cool down your machine completely making sure their is ZERO pressure reading on the pressure gauge AND the

steamer's body including the bottom are cold to the touch. Let it sit overnight unplugged if you are unsure. Once depressurized and cold drain

the water from the bottom of the machine using the easy thumb screw drain plug. Allow to drain until no more water comes out. It is a fast

and simple process that is strongly recommended. Following this simple procedure may extend the life of your system and reduce the need

for repair or service in the long term.

✓Clean Your Boiler: It is advisable to de-mineralize your boiler after approximately 200 to 400 hours of use. For typical use this means cleaning

your system once every 2 to 8 to weeks. Using filtered water (Strongly recommended) reduces build up of gunk in your boiler.

✓How to Clean Your Boiler: Cleaning is easy. Simply drain the boiler using the drain plug on the bottom of the machine (be sure unit is cold

first!) and empty the water in the refill tank that sits on top of the machine. Use the same kind of solution you would use when cleaning your

coffee maker. Distilled White Vinagar is cheap and works great. See your local grocery store. Fill the top left Jug with this 50/50 solution of

White Distilled Vinagar & water. Turn on the machine and let it pump the solution down into the tank. This may take as much as 7 minutes.

DO NOT LEAVE UNATTENDED! DO NOT HEAT THE MACHINE UP! Once the transfer is complete (pump will stop buzzing) simply turn your

machine off and unplug it. Let it sit for 6 to 12 hours for maximum de-scaling and cleaning effect. NEXT: Drain the boiler completely. Catch and

examine dirty water. Remember, empty it all. Empty the refill tank located on the top of the machine and rinse it out. Fill this tank with fresh

clean water. Put the drain plug back in the bottom of the machine and turn it on. Let the boiler fill but DO NOT HEAT THE MACHINE. Once the

boiler is full, empty the boiler again. Gently rock the machine back and forth to help shake out any dirty material that may be in the boiler.

Repeat this process until you get clean water out of the boiler. Once done, replace the drain plug and go back to normal use. Your boiler is

now tuned up and ready for action.