7

3 General safety precautions during use

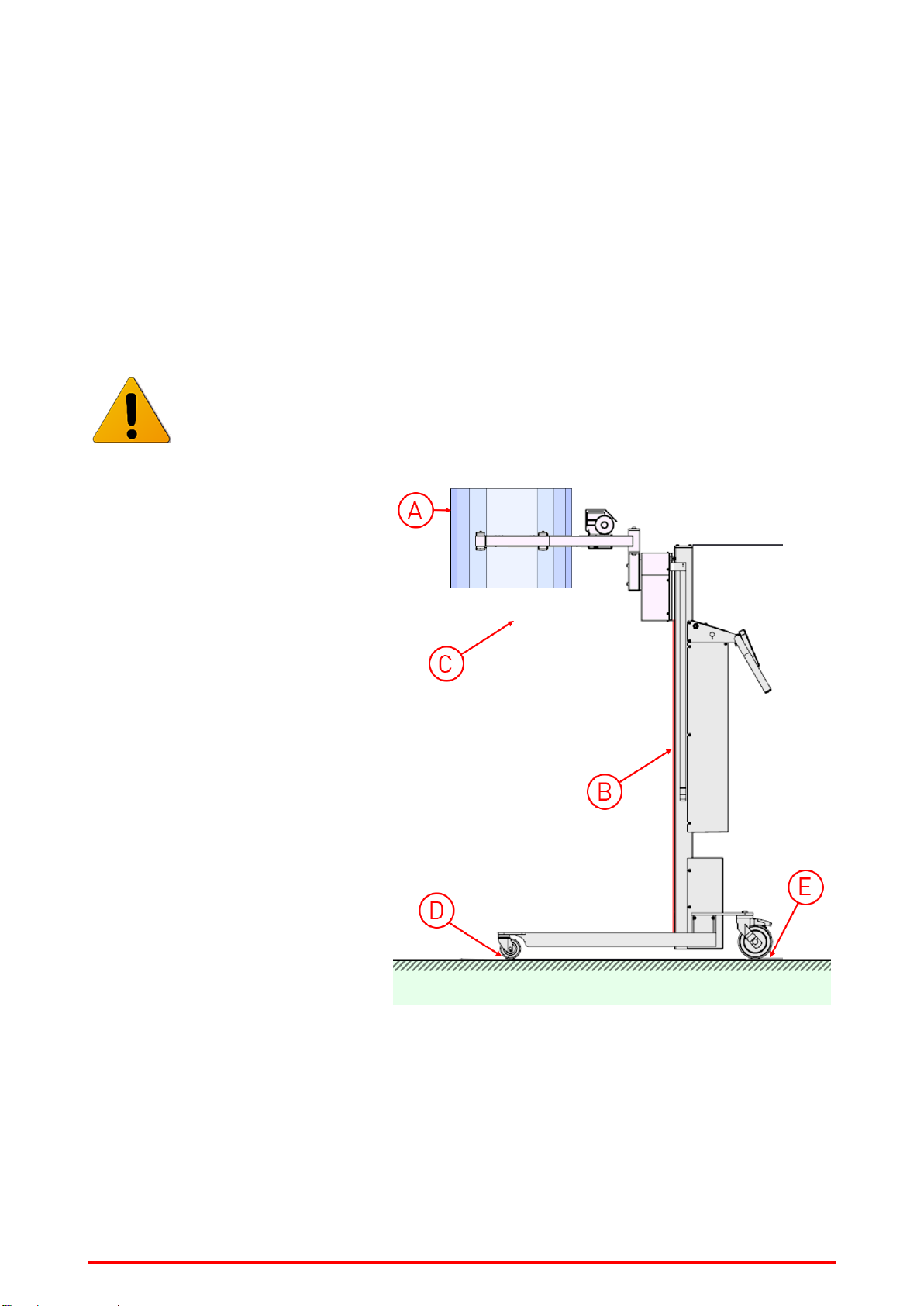

The following guidelines must be observed and followed when using a lift, to prevent personal injury:

lUnder no circumstances should the lift elevate more than specified on the label.

lIt is of most importance, due to personal safety, that the specified weight, load position,

and height are respected and that the lift is not overloaded.

lThe lift must not be used for lifting persons or live animals.

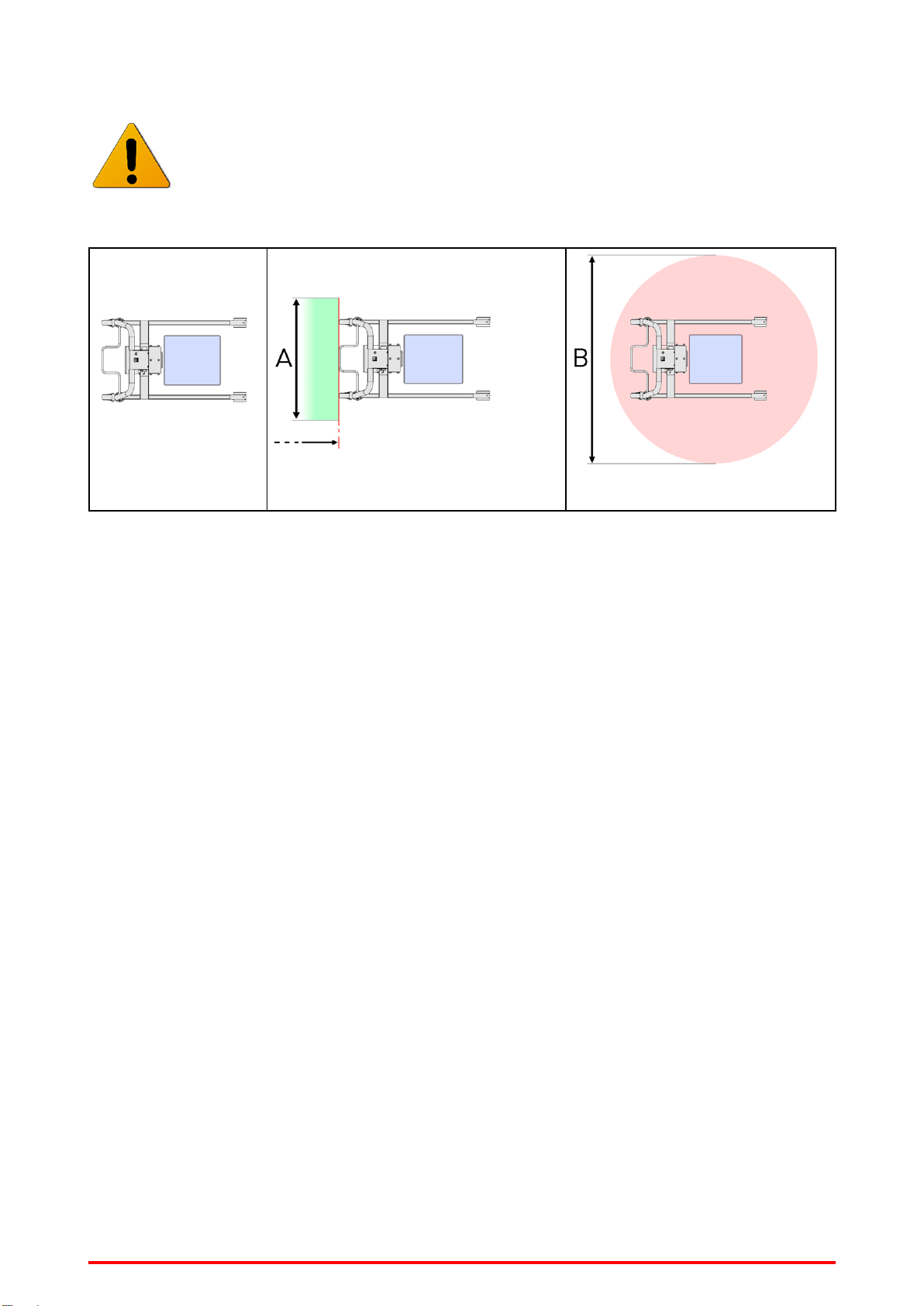

lNo body parts near the sledge or tool at the mast or other lifting equipment when operated

up/down.

lSecure that there is no person below the load, tool and lift when operated.

lThere should be no body parts on top of the front legs steel profile, when the lift is elevated

or operated.

lOnly one person must operate the lift at a time.

lThe user must read and understand these instructions or must have them explained to

them before using the lifter.

lOnly use the lift when operated on a hard-levelled surface during lifting or transporting

loads.

lWhen transporting a cargo, the load should be lowered to the lowest possible position and

secured in order to ensure that the cargo cannot slide.

lAlways secure the cargo on the lift when moving.

lNot in use or storing, always ensure that the sledge is lowered to the lowest possible pos-

ition and is free of any items or cargo.

lOperate and store in a clean, dry location with temperature from +5 °C to +40 °C.

lMake sure that the tool is firmly attached to the sledge and no slack occurs in the bolt con-

nection.

lThe lifter is to be controlled at least once a year or according to laws, regulations, dir-

ectives, working conditions and experience. The control shall be performed by the man-

ufacturer or a skilled technician. Please check your local requirements.

lDo not lift or handle open containers containing corrosive fluids, harmful to people if

spilled.

lIndustrial or commercial use only.

lIndoor use only.

lDo not use the lifter in explosive or flammable hazard environment.

lDo not use or store in a corrosive environment.