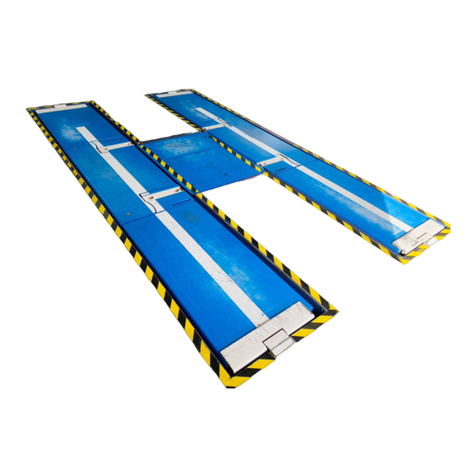

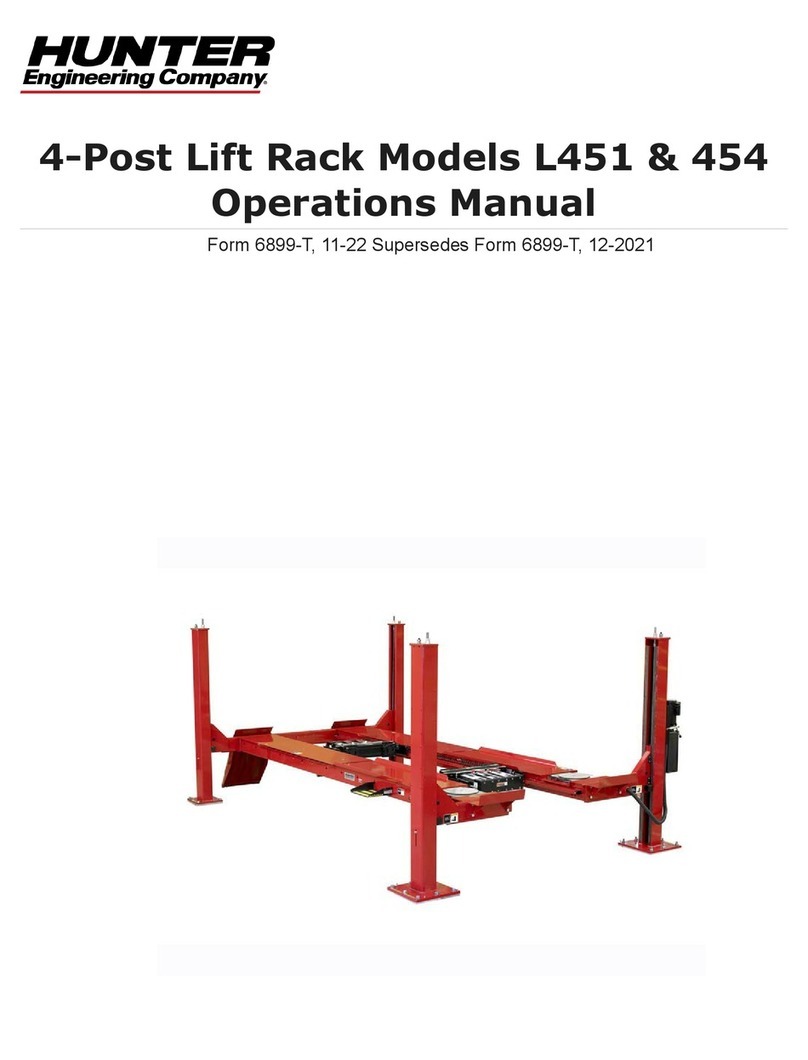

1. This lift is designed for motor vehicle servicing. DO NOT Use for other purpose.

2. If any of safety device does not work properly, DO NOT use lift.

3. Drive in and out vehicle slowly, and DO NOT start and stop suddenly.

4. Pay attention in driving in and out vehicle when tires and drive-on plate are wet to avoid

slipping.

1. When operating the lift, pay constant attention to the area around the vehicle and the lift.

NEVER look aside during operation.

2. If there are other lifts installed in the same site, Pay attention not to operate the control

switch of other lifts.

3. DO NOT lift any vehicle exceeding the maximum capacity of the lift.

4. DO NOT lift vehicles with passengers, baggage or cargo etc.inside.

5. Use only genuine Side Sill Block supporter between upper lift top plate and vehicle lifting

point when lifting vehicle by upper lift.

6. Make sure there is no oil or dirt on supporter when lifting vehicle by upper lift.

7. Stop lifting after supporter have made firm contact with vehicle, and check locations of

supporter for correct lifting points before reraising the vehicle.

8. Stop lifting when lift reached maximum height.

9. During lift lowering operation, wait 1 or 2 seconds before proceeding next lowering operations

10. The lift height of both sides may become unbalanced during lifting and lowering operations.

In such case, follow the instructions of Operation Manual and balance the height of both sides.

If not correcting the unbalance situation, it may result in the fall of the vehicle.

11. If the Jacking Beam is used with Pit Installation Model, DO NOT lower the Lower Lift below

350mm height. Make sure to slide and stow the Jacking Beam into hangar before relowering

lift to floor.

12. If the lift would not lower, raise the lift and then relower.

13. Make sure lift and lift supporters are fully lowered before driving in or out vehicle.

14. Before lowering the lift, ensure that no person or objects is around vehicle or lift.

15. DO NOT operate the lift with anything such as tools or parts left in the pit or under the lift.

Failure to comply may result in failure of the lift or falling of the vehicle.

16. When use Upper Lift, make sure to lift up to max height to avoid unbalance.

1. Make sure Safety Hooks are engaged before getting under vehicle.

2. When working on a vehicle in raised position, make sure the lift is above the position that

Safety Hook is engaged at least with 1st ratchet (Cut out) from the bottom. The lift may drift

down (Natural Lowering), causing damage to the vehicle or equipment,tools, or the like nearby.

3. Keep anyone but the operator out from around the lift.

4. DO NOT leave a vehicle on the lift for long time.

5. When not in use, the lift must be lowered to the lowest position. Even when not in use, raise

and lower the lift all the way through the range at least once a day to maximize the lift life

6. When lowering the lift of Alignment Model(MUL30H), make sure to set all 8 legs are folded or

set(fixed) firmly. If the legs are not set firmly, or floor conditions are not flat, the legs

might get out of place, and dangerous.

7. After vehicle servicing work, lower the lift to bottom and turn off the power.

1. DO NOT modify the lift without permission from the manufacturer. Failure to comply may result

in insufficient performance and lead to serious accident.

2. When an abnormality is detected during use or inspection, stop the use of the lift immediately

and repair. DO NOT use lift until the repair is completed.

3. This lift is not weatherproof and is not to be used outdoors or for vehicle washing.

4. Do not supply air with air pressure exceeding 1.0 MPa to the filter regulator. Or it may damage

the filter regulator.

5. The filter regulator must be set to 0.5 Mpa. If it is set to over 0.5 Mpa, it may damage the

Selex Valve.