Doc. nr. : 012257 Version: V1.9 Date: 16-02-2011

VDH Products B.V. Type: MANUAL FC500-PC Page: 6 of 43

TABLE OF CONTENTS:

INTRODUCTION ..................................................................3

WARNINGS ............................................................3

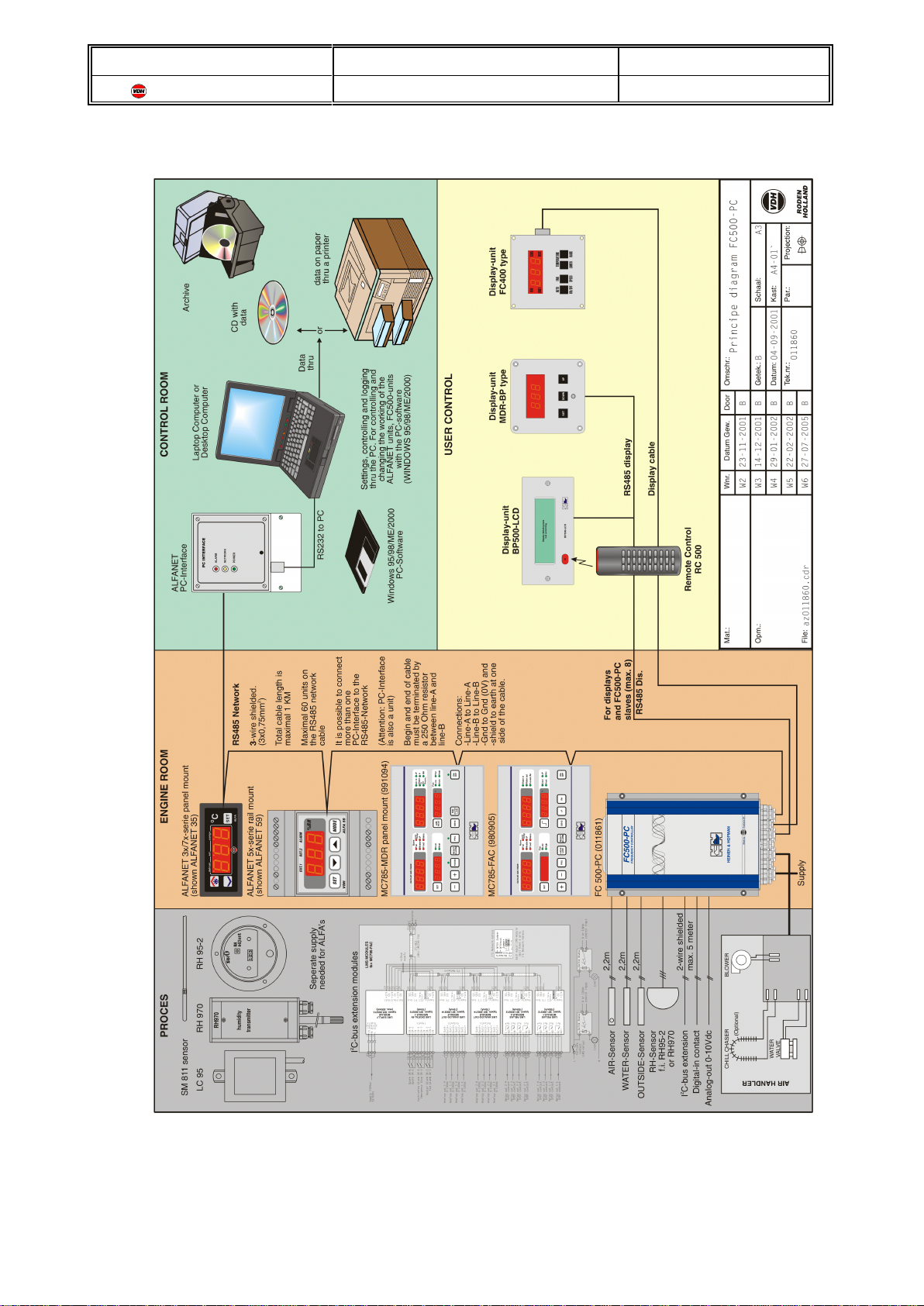

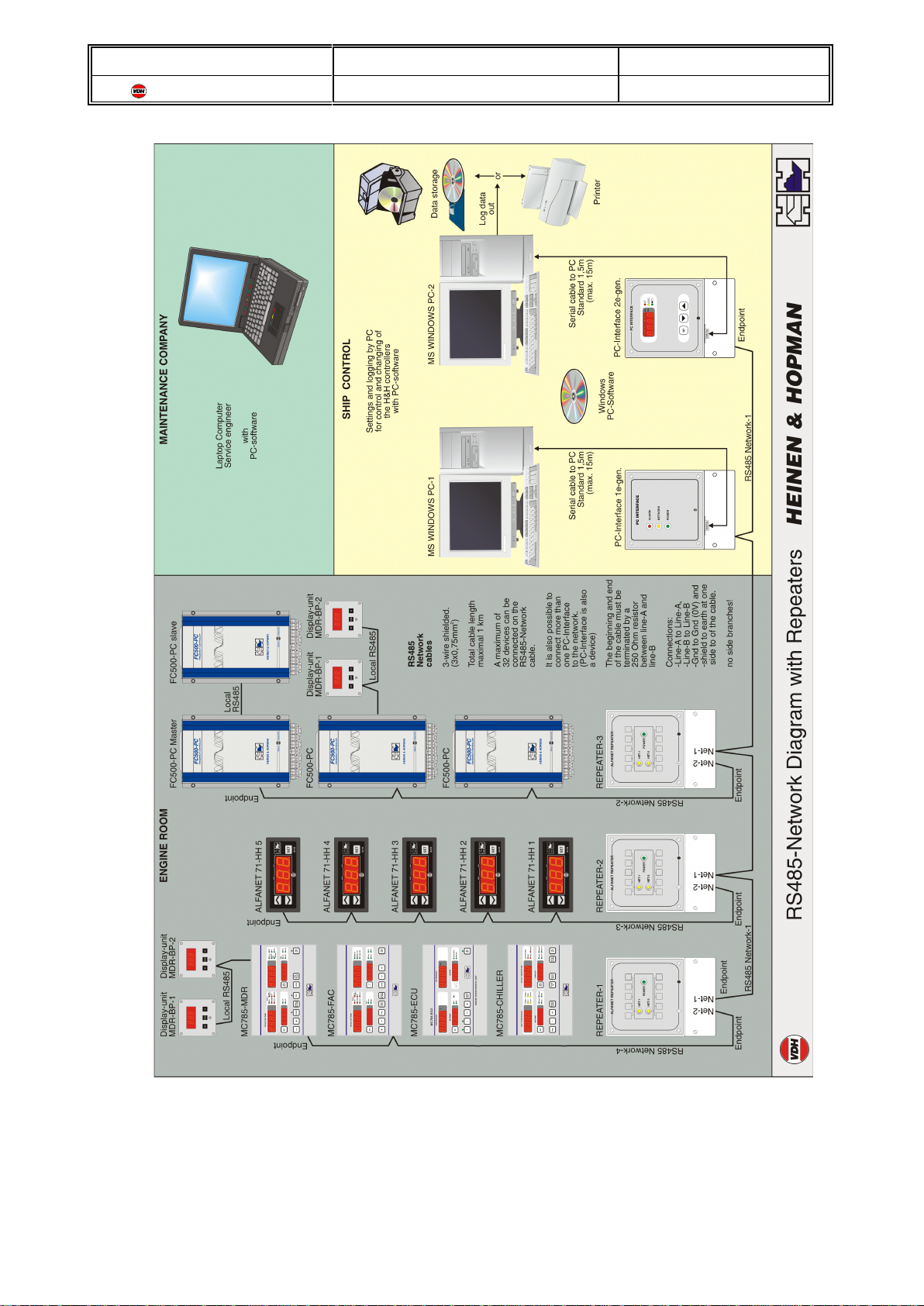

OVERVIEW FC500-SYSTEM ..............................................4

TABLE OF CONTENTS .............................................................6

TECHNICAL DATA ................................................................8

SAFETY INSTRUCTIONS ..........................................................10

ELECTRIC SHOCK PREVENTION .........................................10

FIRE PREVENTION ....................................................10

INJURY PREVENTION ..................................................10

ADDITIONAL INSTRUCTIONS ............................................11

Transportation and Installation ....................................11

Wiring .......................................................12

Trial Run .....................................................12

Emergency Stop ...............................................13

Operation .....................................................13

Maintenance, Inspection and Parts Replacement ......................13

Disposing of the Unit ............................................13

General Instructions ............................................13

INSTALLATION ..................................................................14

Unpacking the FC500-PC unit .............................................14

Installation of the FC500-PC ..............................................14

Opening front-cover of the FC500-PC .......................................15

Terminal connection diagram of the FC500-PC ...............................16

Power connection terminals of the FC500-PC .................................17

Power connections .............................................17

Supply connection ..............................................17

Air Handler connection ..........................................18

Control connection terminals of the FC500-PC ................................19

Control connections .............................................19

T1 = Air temperature sensor connection .............................19

T2 = Water temperature sensor connection ..........................19

T3 = Outside temperature sensor connection .........................19

Humidity sensor connection ......................................20

I2C-BUS connection .............................................20

Analog output connection ........................................20

RS485-NET communication connection .............................21

RS485-DIS (Local) communication connection .......................22

Display data connection .........................................23

CONTROL ......................................................................24

Switching the controller on or off ...........................................24

Adjusting the temperature: ................................................24

Adjusting the fan speed: .................................................24

Adjusting the fan speed without temperature control: ...........................24

Switching off the display: .................................................25

Viewing other measurements: .............................................25

PROGRAMMING PARAMETERS ....................................................25

Parameters .................................................................26

Setting Master/Slave configuration (P91) .........................................27

Setting the RS485 as ALFANET or as MODBUS configuration (P93) ...................28

Night temperature offset (P70) ..................................................28

Setting 230Vac output (P51..P66) ...............................................28

Setting 120Vac output (P51...P66) ..............................................29