range is about 2.7mm/s to 27mm/s.

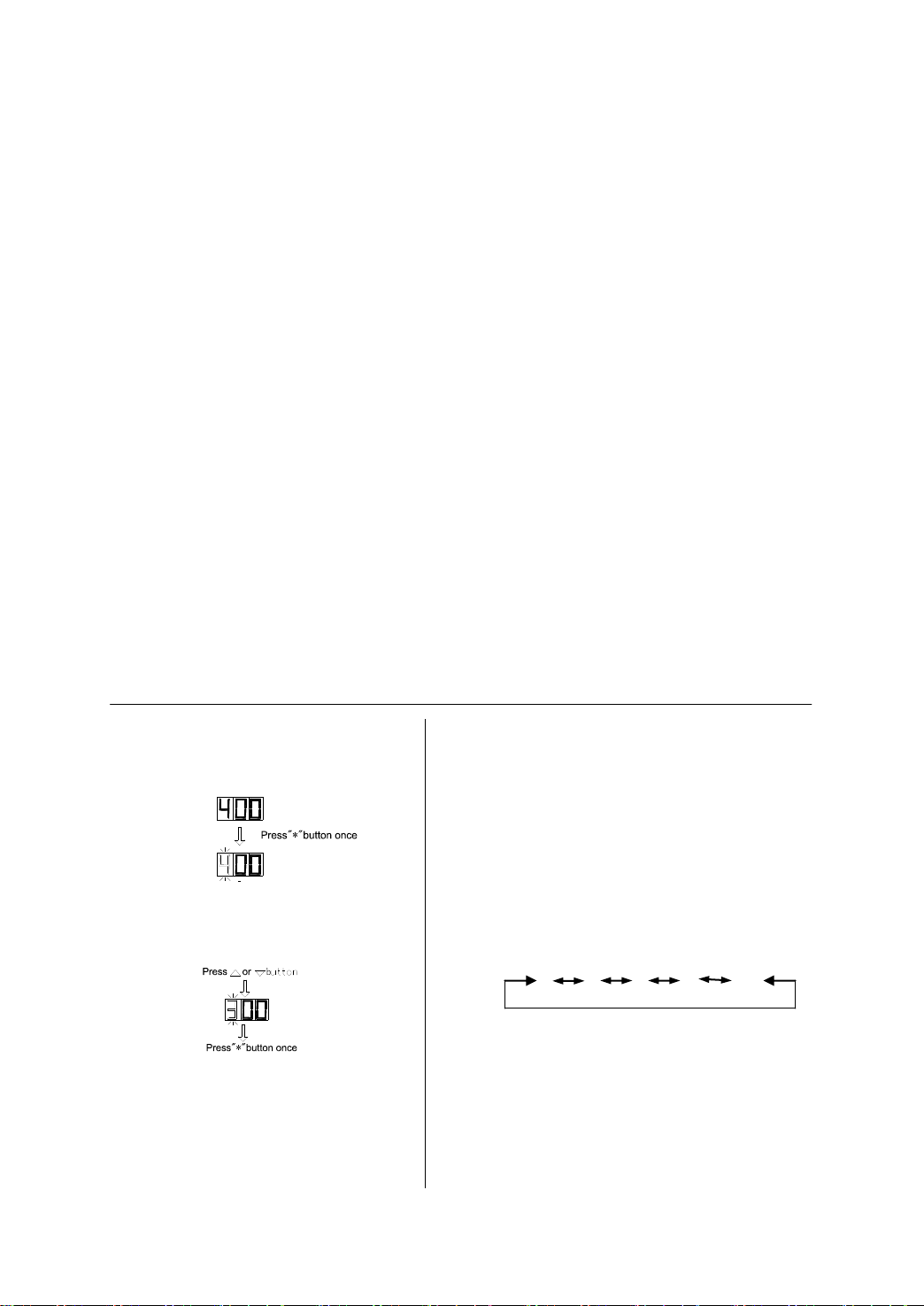

2. Feeding Length setting

Feeding Length is designed with angle system, namely, with angle what the motor turned

denotes Feeding Length.

Feeding Length is designed with three digit. 001 to 999 denotes feeding length is 0.15mm to

150mm. The resolution is 0.15mm, namely, each digit denotes 0.15mm (1.8 degree). The

setting method is the same as feeding speed.

Example: When the digit is set as 001, the angle is 1.8 degree and the Speed Length is

0.15mm. When the digit is set as 002, the angle is 3.6 degree and the Speed Length is 0.3mm.

When the digit is set as 999, the Speed Length is longest with 150mm, and the angle is 1798.2

degree.

Press the Length Switch to set the suitable digit in accordance with working demand. The

range is about 0.15mm to 150mm.

3. Feeding Interval Time setting

Feeding Interval Time means the interval time between every feeding when the automatic

feeding over two times. Feeding Interval Time is designed with one digit. 0 to 9 denotes the

interval time is 0 second to 2.7seconds. The resolution is 0.3 second, namely, each digit

denotes 0.3 second. The setting method is the same as Feeding Speed.

Example: When the digit is set as 1, the interval time is 0.3 second. When it is set as 2, the

interval is 0.6 second. When it is set as 9, the time is longest with 2.7 seconds.

Press the Interval Time Switch to choose the digit. The range is 0 second to 2.7 seconds.

4. Feeding Mode setting

Press the Feeding Mode Switch to choose suitable digit.

Feeding Mode is designed with one digit and the setting method is the same as above. The

digital match function as follow:

0: Manual Feeding 1: Auto Feeding once

2: Auto Feeding twice 3: Auto Feeding three times

4: Auto Feeding four times 5: Auto Feeding five times

6: Auto Feeding six times 7: Auto Feeding seven times

8: Auto Feeding eight times 9: Auto Feeding nine times

After each feeding, it has returning.

5. Returning Time setting

Press Returning Switch to set the match digit in accordance with working demand.

Returning Time is designed with one digit. 0 to 9 denotes 0 second to 0.9 second. The

resolution is 0.1 second, namely, each digit denotes 0.1 second. The returning speed is fixed