1. Safety Instructions............................................................................... 1

2. Overview................................................................................................2

3. Product Characteristics.......................................................................2

4. Product Specifications.........................................................................3

5. Functional Descriptions.......................................................................4

5.1. Dimensions................................................................................ 4

5.2. Part Descriptions.......................................................................4

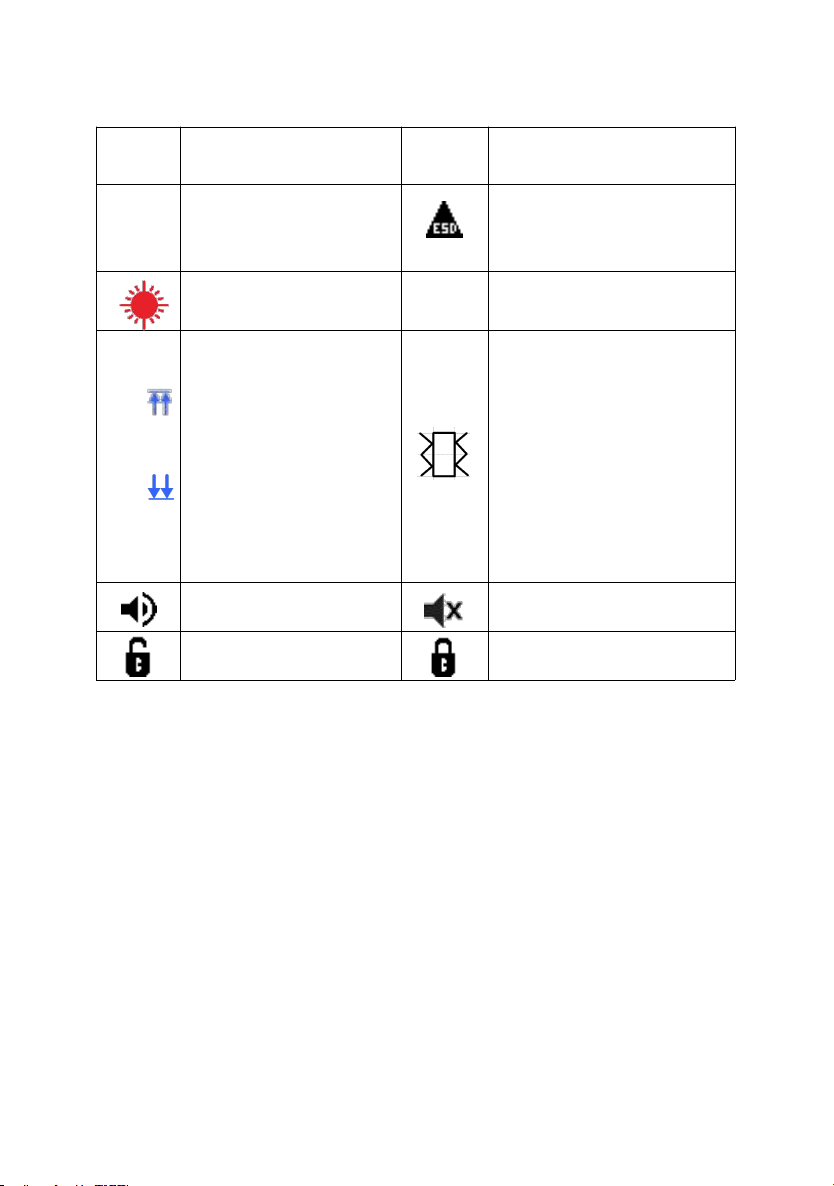

5.3. Key Descriptions.......................................................................5

5.4. Function Descriptions of the Main Interface........................ 5

6. Use of Holder and Sponge................................................................. 6

7. Connection............................................................................................ 7

8. Turn On/Off............................................................................................7

9. Temperature Settings.......................................................................... 7

10. Menu Settings.....................................................................................8

10.1. Channel Temperature Settings.............................................8

10.2. Temperature Unit Setting...................................................... 9

10.3. Sleeping Time Setting............................................................9

10.4. Close Time Setting...............................................................10

10.5. Display Setting......................................................................10

10.6. Temperature Limit Alarm Setting....................................... 10

10.7. Password Setting..................................................................11

10.8. ESD Test Settings................................................................ 12

10.9. Soldering Hint Settings........................................................12

10.10. Key tone Settings...............................................................12

10.11. Patterns............................................................................... 13

10.12. Language Settings.............................................................13