2

Contents

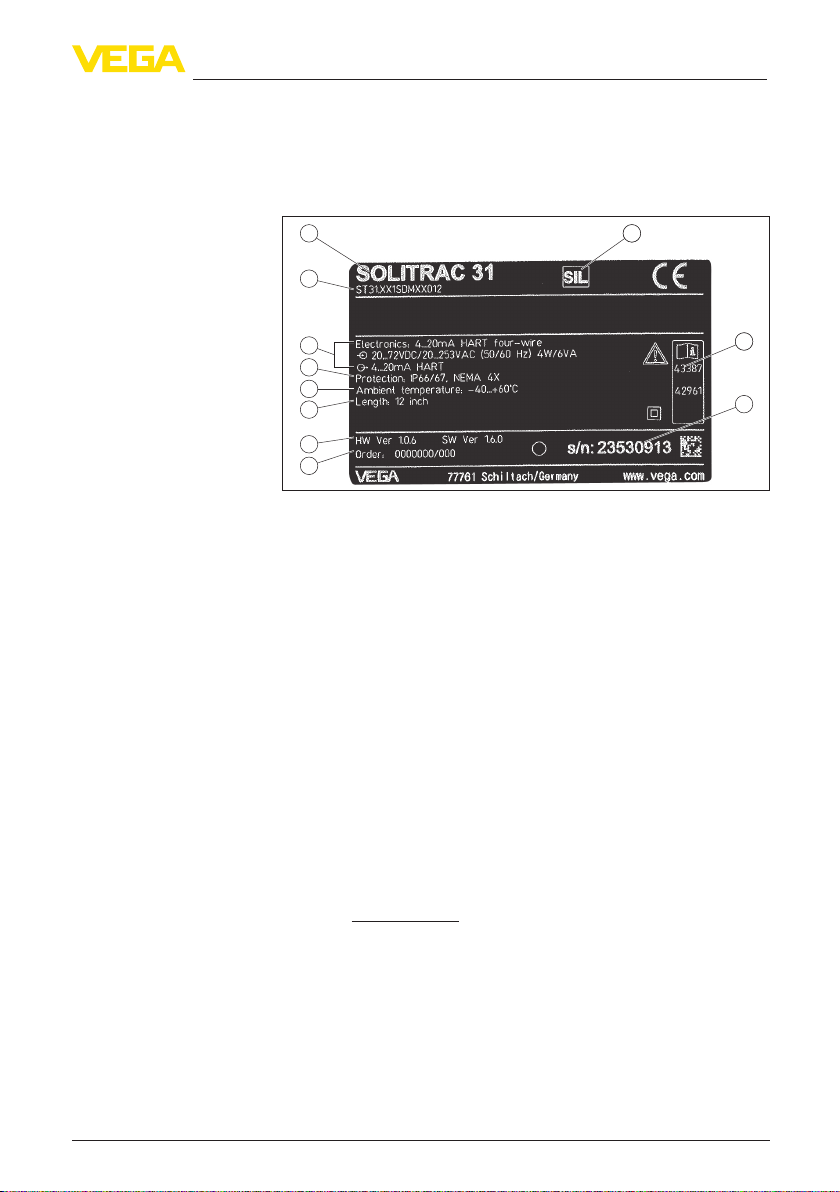

SOLITRAC 31 • Four-wire 4 … 20 mA/HART

62085-EN-211203

Contents

1 For your safety ......................................................................................................................... 3

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use................................................................................................................ 3

1.3 Warning about incorrect use............................................................................................. 3

1.4 General safety instructions............................................................................................... 3

1.5 EU conformity................................................................................................................... 3

1.6 NAMUR recommendations .............................................................................................. 4

1.7 Installation and operation in the USA and Canada ........................................................... 4

1.8 Environmental instructions ............................................................................................... 4

2 Product description ................................................................................................................. 5

2.1 Conguration.................................................................................................................... 5

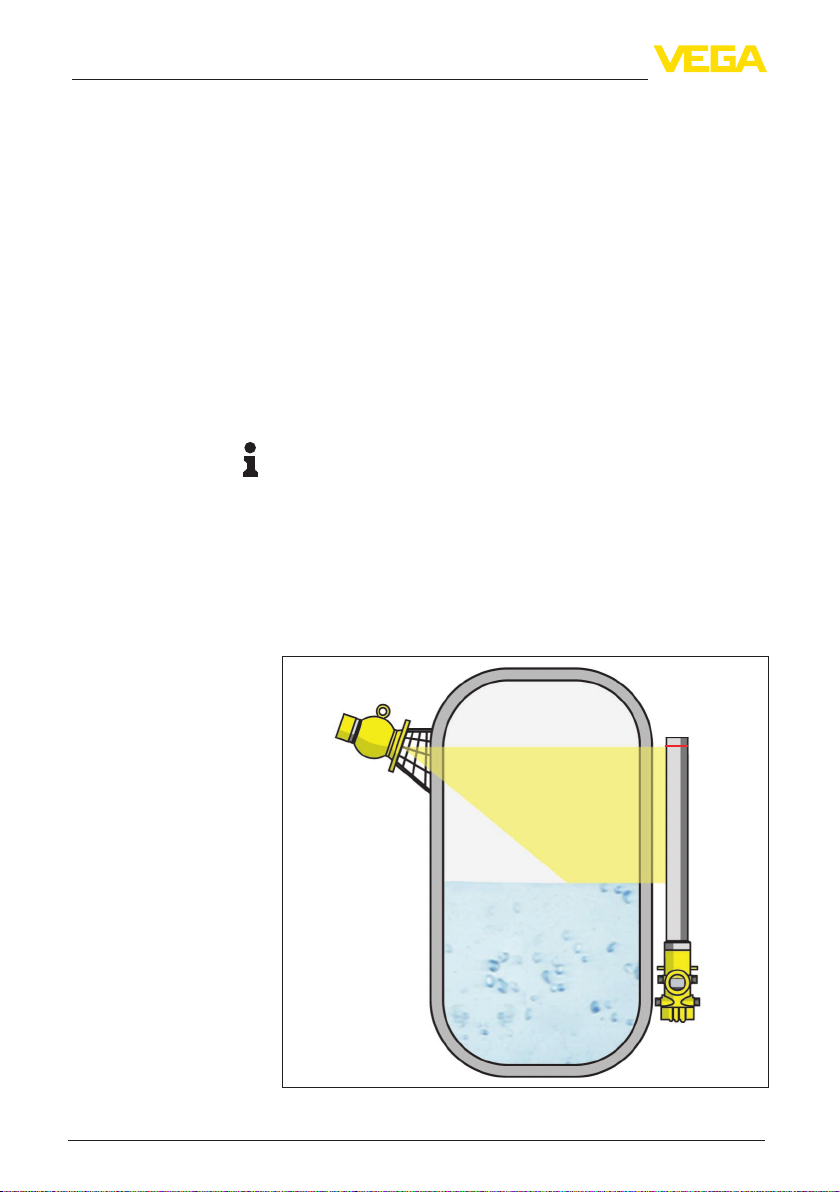

2.2 Principle of operation........................................................................................................ 6

2.3 System limitations ............................................................................................................ 6

2.4 Corresponding source container...................................................................................... 7

3 Mounting................................................................................................................................... 9

3.1 General instructions ......................................................................................................... 9

3.2 Mounting instructions ..................................................................................................... 10

4 Connecting to power supply................................................................................................. 14

4.1 Preparing the connection ............................................................................................... 14

4.2 Connection - Level measurement................................................................................... 16

4.3 Connection - Level detection.......................................................................................... 18

4.4 Connection - Summation................................................................................................ 20

5 Functional safety (SIL) .......................................................................................................... 22

5.1 Objective........................................................................................................................ 22

5.2 SILqualication.............................................................................................................. 22

5.3 Application area ............................................................................................................. 22

5.4 Safety concept of the parameterization .......................................................................... 23

6 Set up with the display and adjustment module ................................................................ 25

6.1 Insert display and adjustment module............................................................................ 25

6.2 Parameter adjustment - Summation Secondary............................................................. 25

7 Supplement ............................................................................................................................ 27

7.1 Technical data ................................................................................................................ 27

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

Youcanndsupplementaryinformationinthecorresponding,more

detailed Operating Instructions Manual as well as the Safety Manual

thatcomeswithinstrumentswithSILqualication.Thesemanualsare

available on our homepage.

Operating instructions SOLITRAC 31, four-wire 4 … 20 mA/

HART, with SIL qualication: Document-ID 43387

Editing status of the quick setup guide: 2021-11-25