2

Contents

WEIGHTRAC 31 • Probus PA

43837-EN-200522

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 EU conformity................................................................................................................... 6

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Installation and operation in the USA and Canada ........................................................... 6

2.8 Environmental instructions ............................................................................................... 6

3 Product description ................................................................................................................. 7

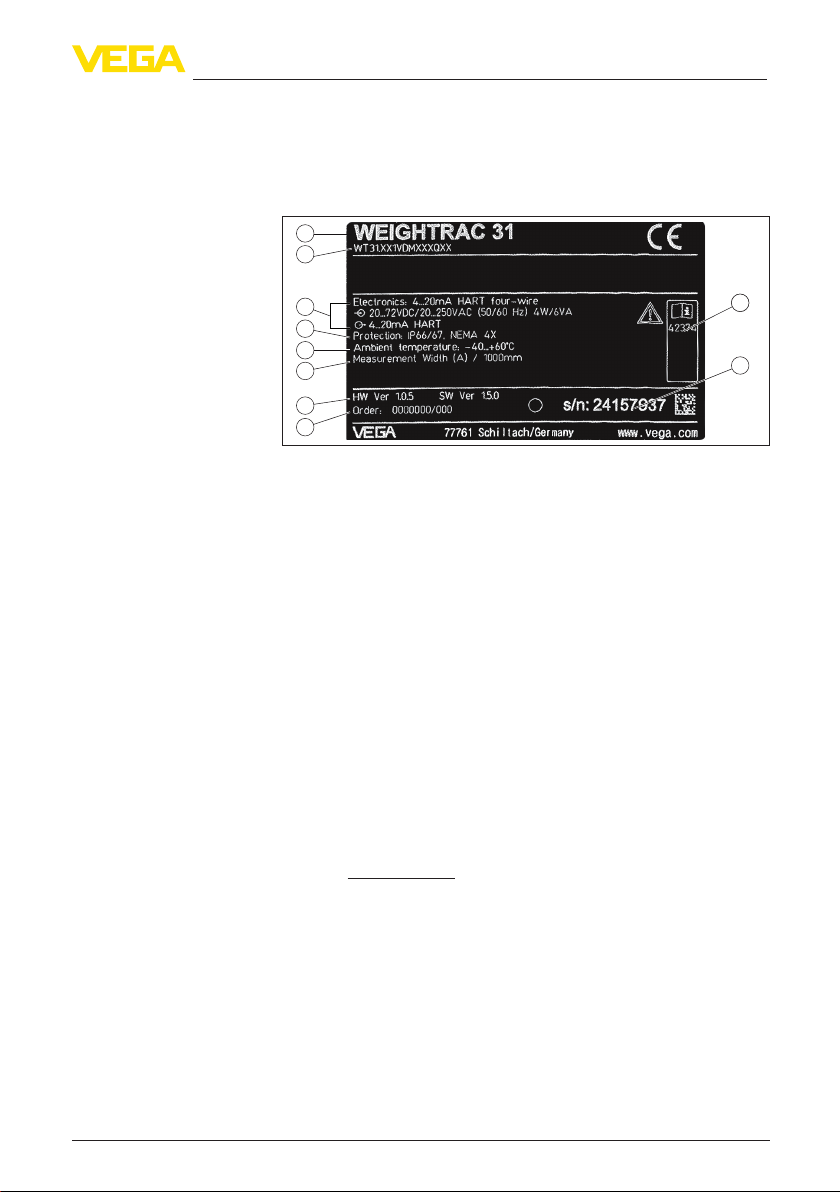

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Packaging, transport and storage..................................................................................... 9

3.4 Accessories...................................................................................................................... 9

3.5 Corresponding source container .................................................................................... 11

4 Mounting................................................................................................................................. 13

4.1 General instructions ....................................................................................................... 13

4.2 Mounting instructions ..................................................................................................... 14

5 Connecting to power supply................................................................................................. 24

5.1 Preparing the connection ............................................................................................... 24

5.2 Connection - Mass ow determination ........................................................................... 27

5.3 Connection - Summation................................................................................................ 29

5.4 Connection - Tachometer ............................................................................................... 31

5.5 Set instrument address .................................................................................................. 33

6 Adjustment with the display and adjustment module........................................................ 35

6.1 Insert display and adjustment module............................................................................ 35

6.2 Adjustment system......................................................................................................... 36

6.3 Display and adjustment module - Indication of system parameters................................ 37

6.4 Saving the parameterisation data................................................................................... 42

7 Setup with PACTware............................................................................................................. 43

7.1 Connect the PC.............................................................................................................. 43

7.2 Parameter adjustment with PACTware............................................................................ 43

7.3 Parameter adjustment - Mass ow detection.................................................................. 44

7.4 Saving the parameterisation data................................................................................... 60

8 Diagnostics and servicing .................................................................................................... 61

8.1 Maintenance .................................................................................................................. 61

8.2 Status messages............................................................................................................ 61

8.3 Rectify faults................................................................................................................... 64

8.4 Exchanging the electronics module................................................................................ 65

8.5 Software update............................................................................................................. 66

8.6 How to proceed if a repair is necessary.......................................................................... 66