2

Contents

VEGACAL 66 • For connection to a controller

30321-EN-200929

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 EU conformity................................................................................................................... 5

2.6 Installation and operation in the USA and Canada ........................................................... 6

2.7 Safety instructions for Ex areas ........................................................................................ 6

2.8 Environmental instructions ............................................................................................... 6

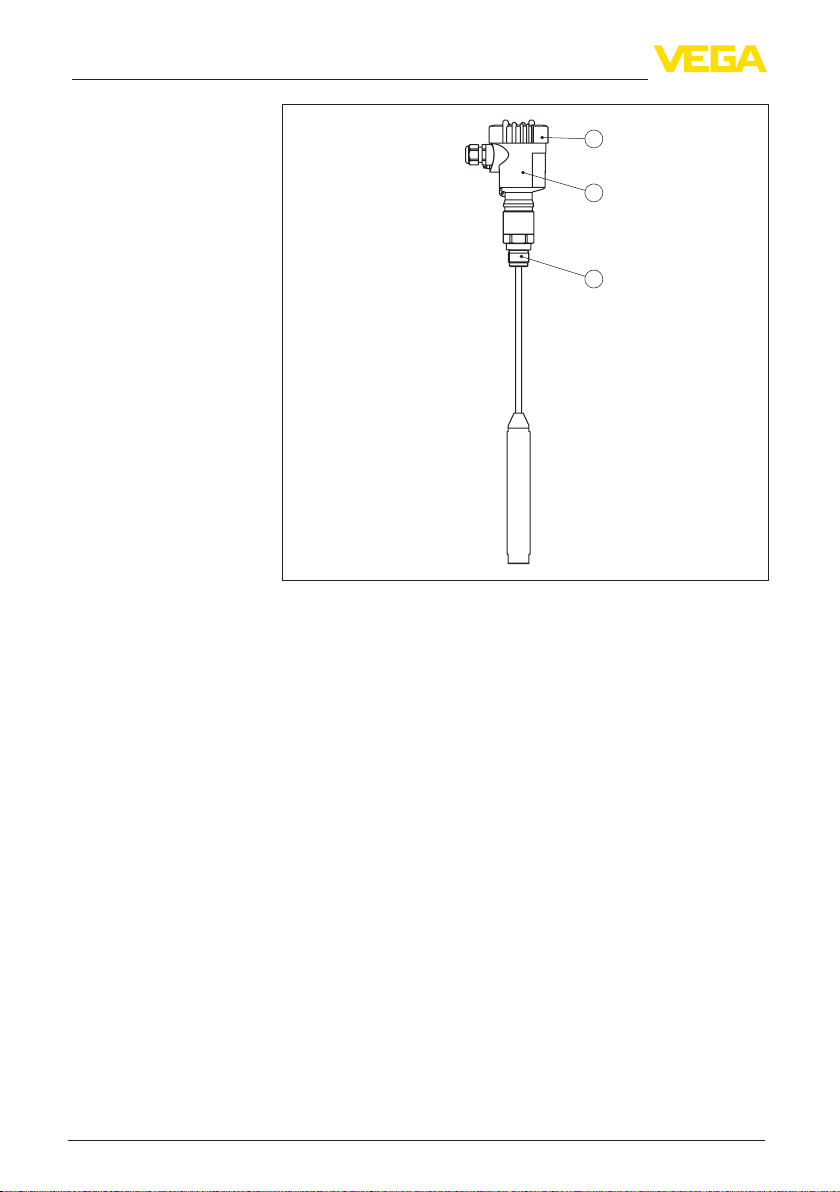

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation...................................................................................................... 10

3.3 Adjustment ..................................................................................................................... 10

3.4 Packaging, transport and storage................................................................................... 11

3.5 Accessories.................................................................................................................... 11

4 Mounting................................................................................................................................. 13

4.1 General instructions ....................................................................................................... 13

4.2 Mounting instructions ..................................................................................................... 15

5 Connecting to power supply................................................................................................. 17

5.1 Preparing the connection ............................................................................................... 17

5.2 Connection procedure.................................................................................................... 18

5.3 Wiring plan, single chamber housing.............................................................................. 19

5.4 Wiring plan - version IP66/IP68, 1 bar ............................................................................ 20

6 Setup with a controller .......................................................................................................... 21

6.1 General information........................................................................................................ 21

6.2 Adjustment system......................................................................................................... 21

6.3 Continuous level measurement...................................................................................... 22

7 Maintenanceandfaultrectication...................................................................................... 24

7.1 Maintenance .................................................................................................................. 24

7.2 Rectify faults................................................................................................................... 24

7.3 Exchanging the electronics module................................................................................ 25

7.4 How to proceed if a repair is necessary.......................................................................... 26

8 Dismount................................................................................................................................. 27

8.1 Dismounting steps.......................................................................................................... 27

8.2 Disposal ......................................................................................................................... 27

9 Supplement ............................................................................................................................ 28

9.1 Technical data ................................................................................................................ 28

9.2 Dimensions .................................................................................................................... 32

9.3 Industrial property rights................................................................................................. 36

9.4 Trademark ...................................................................................................................... 36