1

Sommario

1. GENERAL INFORMATION..................................................................................................................................2

2. START UP.................................................................................................................................................................3

3. CONNECTIONS.......................................................................................................................................................4

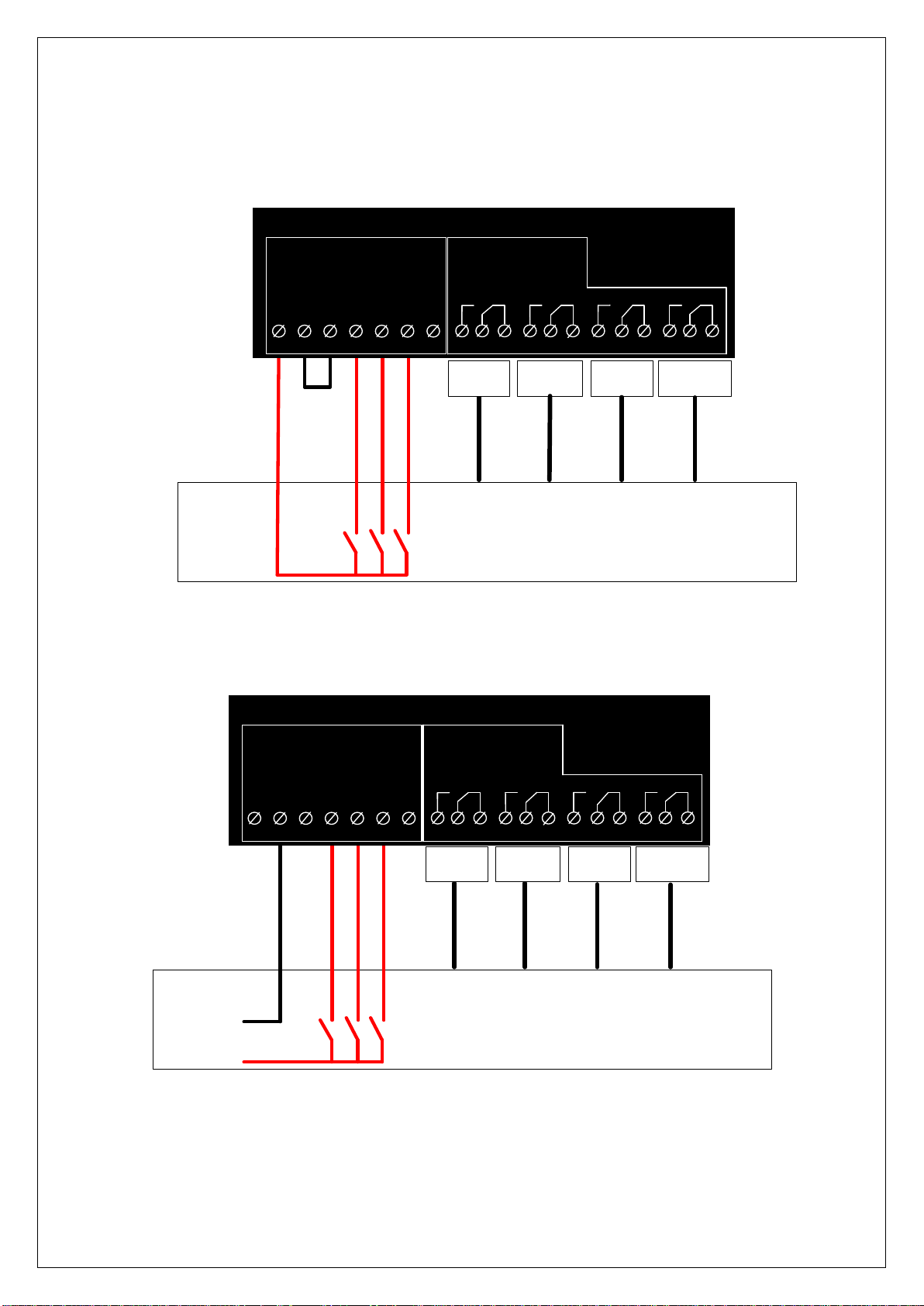

3.1. Opr800-Control Panel.......................................................................................................................................4

3.2. Opr800-Vega Light Curtains.............................................................................................................................5

3.3. Opr800-Light Curtains/Photocell......................................................................................................................5

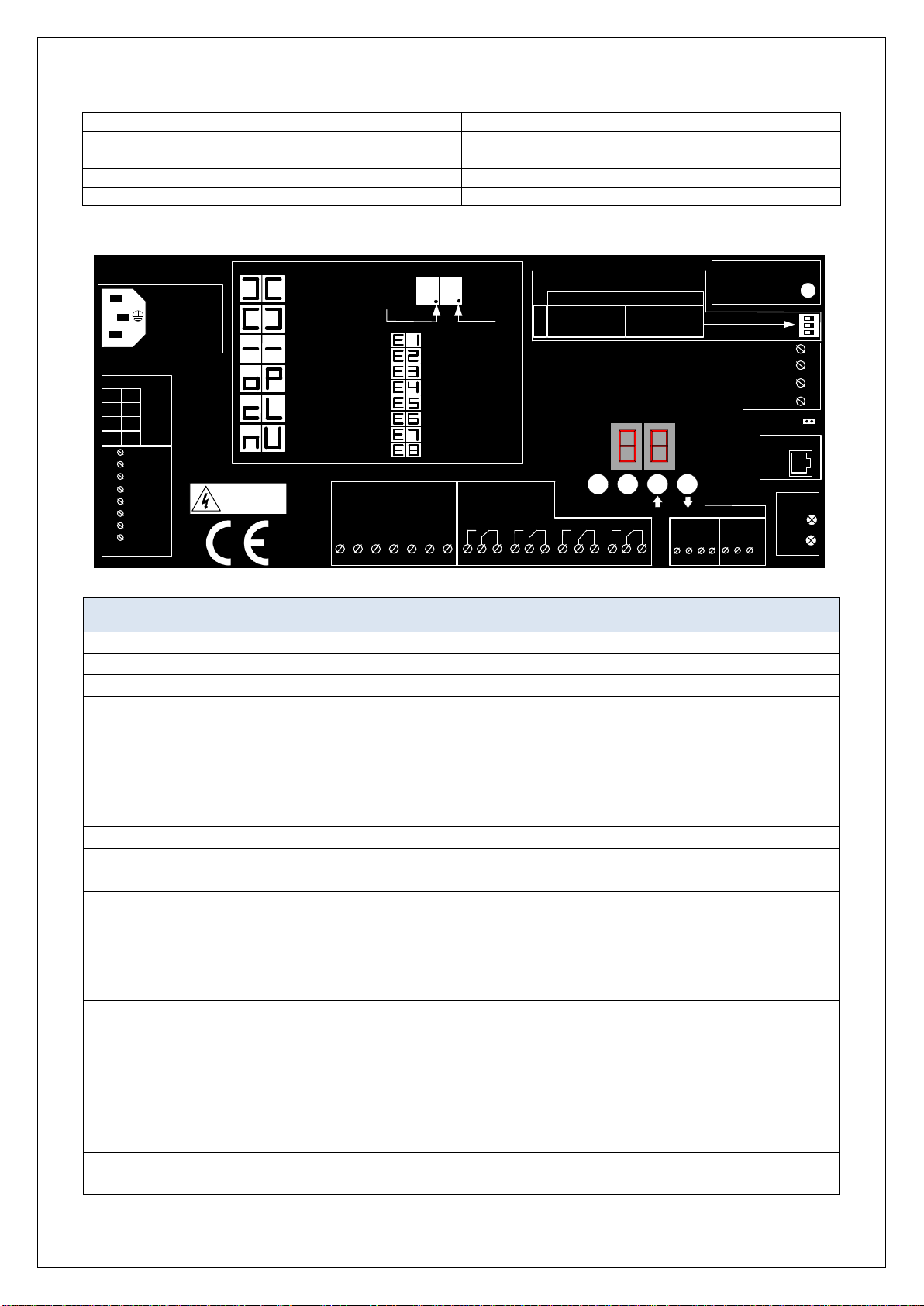

4. USER INTERFACE.................................................................................................................................................6

4.1. Dipswitch ..........................................................................................................................................................6

4.1.1. D1 .................................................................................................................................................................6

4.1.2. D2 .................................................................................................................................................................6

4.1.3. D3 .................................................................................................................................................................6

4.2. TST800..............................................................................................................................................................7

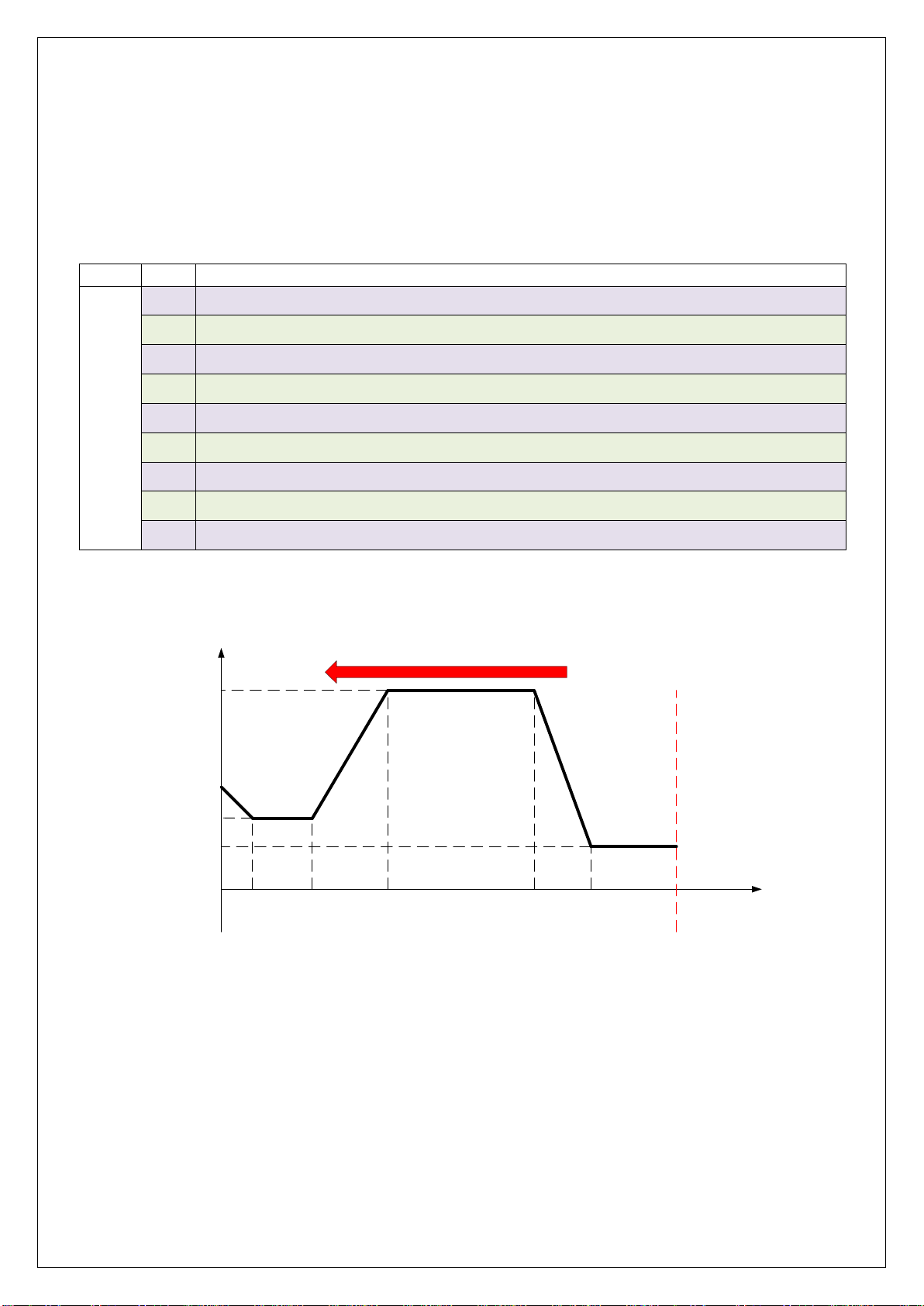

4.2.1. Opening Profile (MO) ..................................................................................................................................7

4.2.2. Closing Profile (M1) ................................................................................................................................8

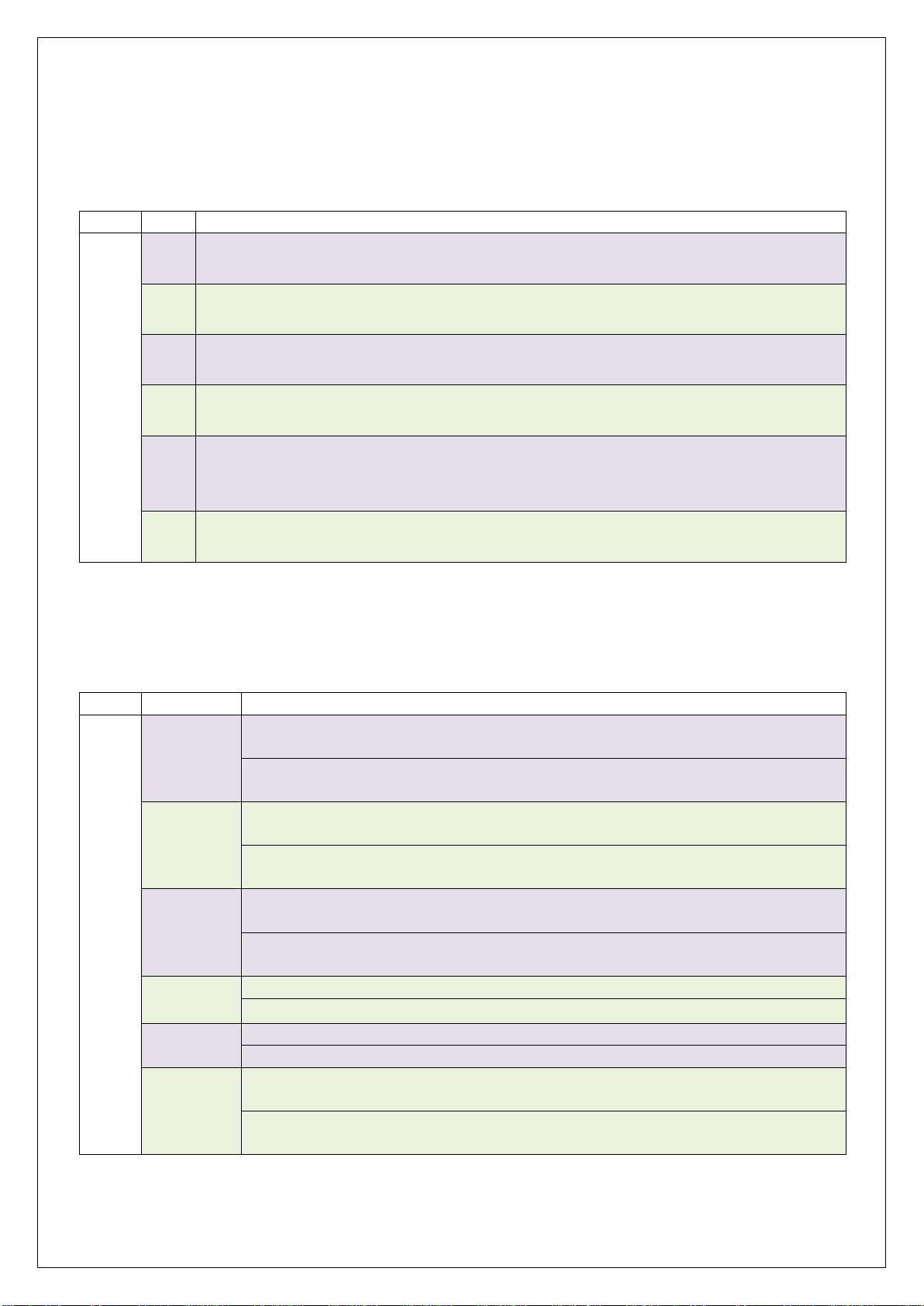

4.2.3. Torques (M2) ...........................................................................................................................................9

4.2.4. Options (M3)............................................................................................................................................9

4.2.5. Commands (M4) ....................................................................................................................................10

4.2.6. Parametri Meccanici (M5)......................................................................................................................10

4.2.7. Light Curtain Parameters (M6) ..............................................................................................................10

4.2.8. 81-20/50 Parameters (M7)......................................................................................................................10

4.2.9. Diagnostic Parameter (M8)....................................................................................................................11

5. FUNCTIONS...........................................................................................................................................................12

5.1. IxT Protection..................................................................................................................................................12

5.2. Security Test Vega Light Curtain....................................................................................................................12

5.3. Reopening to the floor –EN81-20/50 .............................................................................................................12

6. DIAGNOSTIC.........................................................................................................................................................13

6.1. LED.................................................................................................................................................................13

6.2. TST800............................................................................................................................................................14

7. DEFAULT...............................................................................................................................................................15

8. DIMENSIONS.........................................................................................................................................................16

9. TRUBLESHOOTING............................................................................................................................................17