-Safety Manual (SIL) (optional)

-Test certificate measuring accuracy (optional)

-Operating instructions manual "Indicating and adjustment

module"(optional)

-Supplementary instructions "GSM/GPRS radio module"(op-

tional)

-Supplementary instructions manual "Heating for indicating and

adjustment module"(optional)

-Supplementary instructions manual "Plug connector for con-

tinuously measuring sensors"(optional)

-Ex-specific"Safety instructions"(with Ex versions)

-if necessary,further certificates

3.2Principle of operation

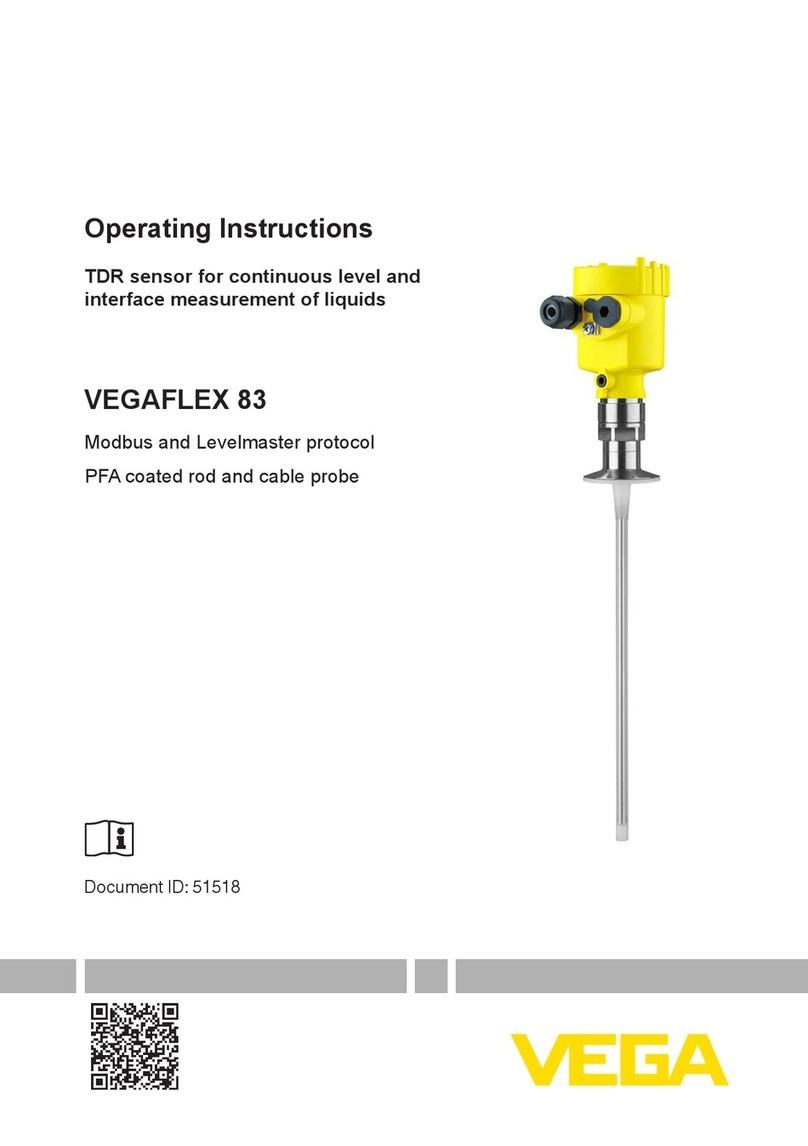

The instrument is designed for level measurement of bulk solids even

under difficult process conditions.Its mechanical construction and

electronics are specially optimised for such applications.Many

application possibilities can be found in the food processing industry,

in plastics processing and steel production as well as in the building

industry.

The instrument is particularly suitable for average-size silos and

vessels.

The instrument is also suitable for applications in liquids.

The use of the instrument is possible with products with an ε

r

value

≥1.5.The reachable value depends on the measurement conditions,

the antenna system,the standpipe or bypass.

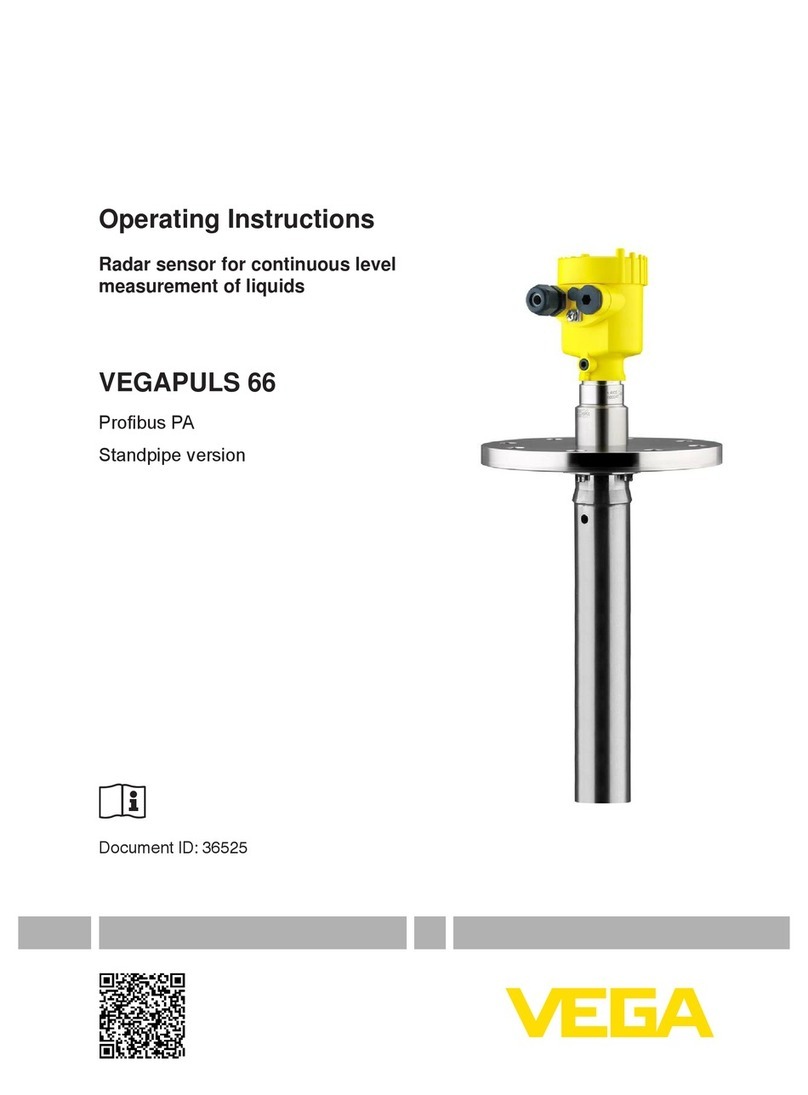

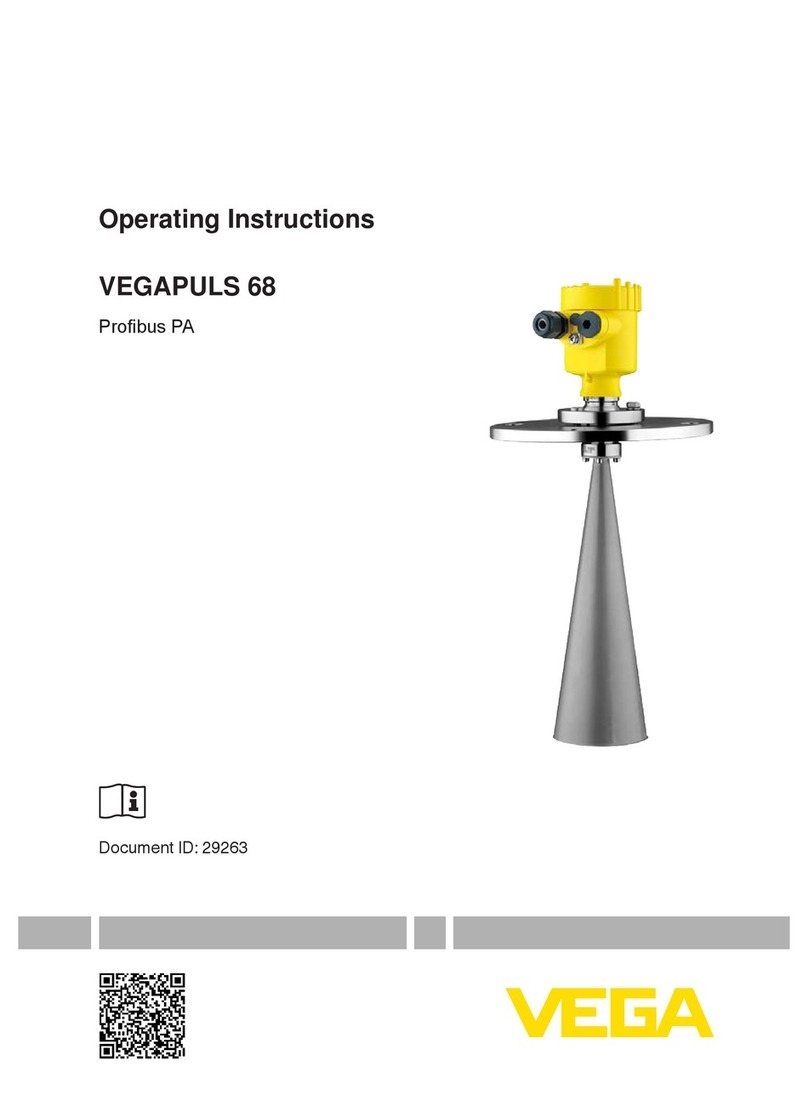

The antenna of the radar sensor emits short radar pulses with a

duration of approx.1ns.These pulses are reflected by the product

and received by the antenna as echoes.The running time of the radar

pulses from emission to reception is proportional to the distance and

hence to the level.The determined level is converted into an

appropriate output signal and outputted as measured value.

3.3Packaging,transport and storage

Your instrument was protected by packaging during transport.Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environment-

friendly,recyclable cardboard.For special versions,PE foam or PE foil

is also used.Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging.Nonobservance of these instructions can cause

damage to the device.

Application area

Functional principle

Packaging

Transport

8VEGAPULS SR 68 •4…20 mA/HART two-wire

3Product description

38294-EN-110209