2

Contents

VEGASWING 51 • - contactless electronic switch

41045-EN-160108

Contents

1 About this document

1.1 Function ........................................................................................................................... 3

1.2 Target group ..................................................................................................................... 3

1.3 Symbols used................................................................................................................... 3

2 For your safety

2.1 Authorised personnel ....................................................................................................... 4

2.2 Appropriate use................................................................................................................ 4

2.3 Warning about incorrect use............................................................................................. 4

2.4 General safety instructions............................................................................................... 4

2.5 Safety label on the instrument .......................................................................................... 5

2.6 CE conformity................................................................................................................... 5

2.7 Environmental instructions ............................................................................................... 5

3 Product description

3.1 Conguration.................................................................................................................... 6

3.2 Principle of operation........................................................................................................ 6

3.3 Operation ......................................................................................................................... 7

3.4 Packaging, transport and storage..................................................................................... 7

4 Mounting

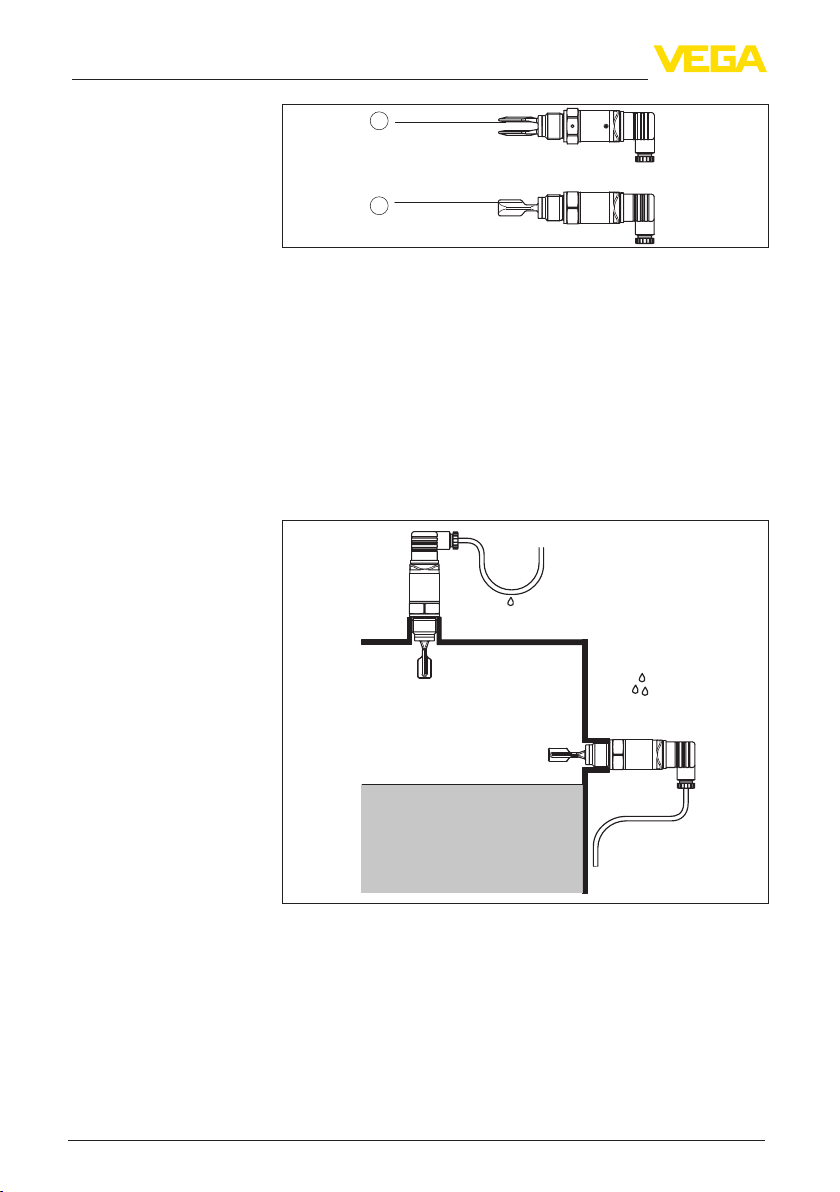

4.1 General instructions ......................................................................................................... 9

4.2 Mounting instructions ..................................................................................................... 11

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 13

5.2 Wiring plan ..................................................................................................................... 14

6 Setup

6.1 Indication of the switching status.................................................................................... 18

6.2 Simulation ...................................................................................................................... 18

6.3 Function table................................................................................................................. 19

7 Maintenanceandfaultrectication

7.1 Maintenance .................................................................................................................. 20

7.2 Rectify faults................................................................................................................... 20

7.3 How to proceed if a repair is necessary.......................................................................... 21

8 Dismount

8.1 Dismounting steps.......................................................................................................... 22

8.2 Disposal ......................................................................................................................... 22

9 Supplement

9.1 Technical data ................................................................................................................ 23

9.2 Dimensions .................................................................................................................... 26

Editing status: 2015-12-29